Page 29

C-Heating Components (FIGURE 14)

1. Ignitor

The SureLight

®

ignitor is made of durable silicon nitride.

Ignitor longevity is enhanced by controlling voltage to the

ignitor. The integrated control provides a regulated 120

volts to the ignitor for a consistent ignition and long ig-

nitor life. Due to this feature of the control, voltage mea-

sured with a digital meter will be slightly lower. To measure

correct voltage use a true RMS meter or ignitor can be

ohmed. Ohm value should be 39 to 70.

2. Flame Sensor

A ame sensor is located on the left side of the burner

support. The sensor is mounted on the ame rollout plate

and the tip protrudes into the ame envelope of the left-

most burner. The sensor can be removed for service with-

out removing any part of the burners. During operation,

ame is sensed by current passed through the ame and

sensing electrode. The SureLight control allows the gas

valve to remain open as long as ame signal is sensed.

To check ame sense signal use the push-button found

on the integrated control and go to Field Test Mode. The

menu will display the ame signal. TABLE 18 shows the

ame signal for the SLP99DFV unit.

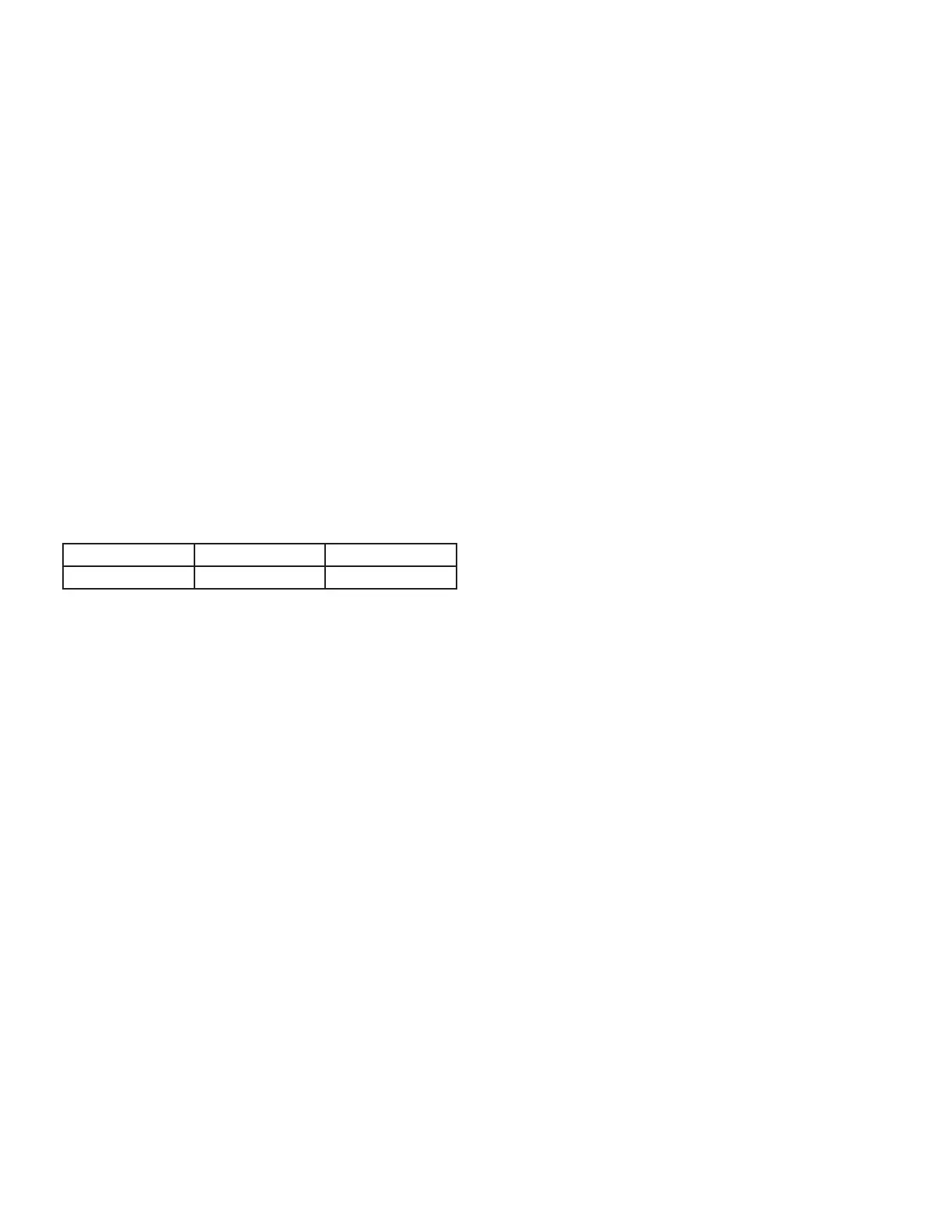

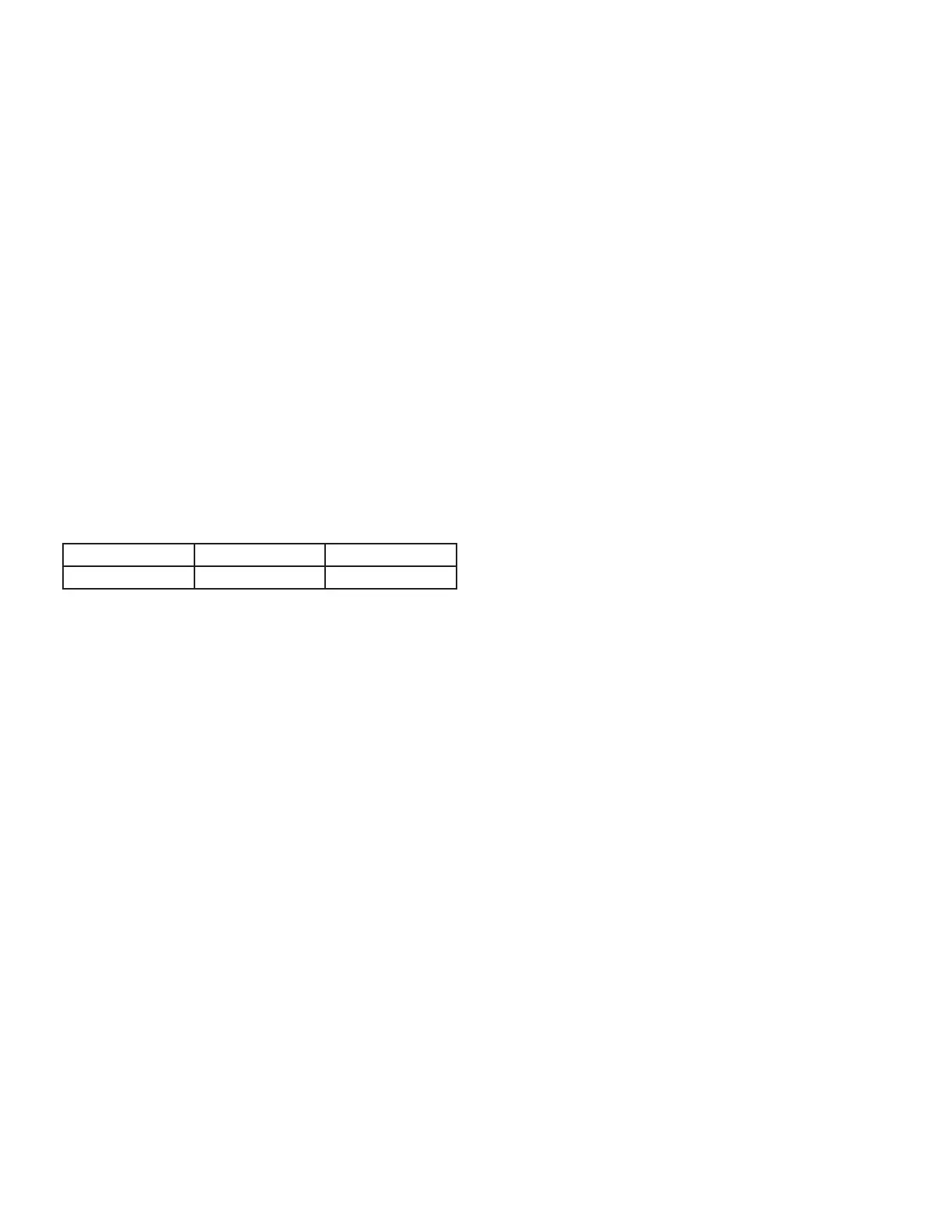

TABLE 18

Flame Signal in Microamps

Normal Low Drop Out

2.6 or greater 2.5 or less 1.1

NOTE - A much higher than normal micro amp reading

(15 for example) may appear when checking ame signal.

3. Flame Rollout Switches

Flame rollout switch S47 is a high temperature limit located

inside the burner box. Each furnace is equipped with two

identical switches. The limit is a N.C. SPST manual-reset

limit connected in series with the primary limit S10.

When S47 senses rollout, the circuit breaks and the inte-

grated control immediately stops ignition and closes the

gas valve. If unit is running and ame rollout is detected,

the gas valve will close and integrated control will be dis-

abled. Rollout can be caused by a blocked heat exchang-

er, ue or lack of combustion air. The switch is factory set

to trip (open) at 210°F and cannot be adjusted. The switch

can be manually reset. To manually reset a tripped switch,

push the reset button located on the center of the switch.

4. Burners

All units use inshot burners. Burners are factory set and

require no adjustment. Always operate the unit with the

burner box front panel in place. Each burner uses an ori-

ce that is precisely matched to the burner input. Burners

can be removed as a one piece assembly for service. If

burner assembly has been removed, it is critical to align

center of each burner to the center of the clamshell when

re-installing. See more detail in Section VII- MAINTE-

NANCE..

5. Duralock Plus Heat Exchanger (FIGURE 15)

Units use an aluminized steel primary and stainless steel

secondary heat exchanger assembly. Heat is transferred

to the air stream from all surfaces of the heat exchanger.

The shape of the heat exchanger ensures maximum e-

ciency.

The combustion air inducer pulls fresh air through the

burner box. This air is mixed with gas in the burners. The

gas / air mixture is then burned at the entrance of each

clamshell. Combustion gases are then pulled through the

primary and secondary heat exchangers and exhausted

out the exhaust vent pipe.

Loading...

Loading...