Page 32

8. Combustion Air Inducer (B6) & Pressure Switch

(S18)

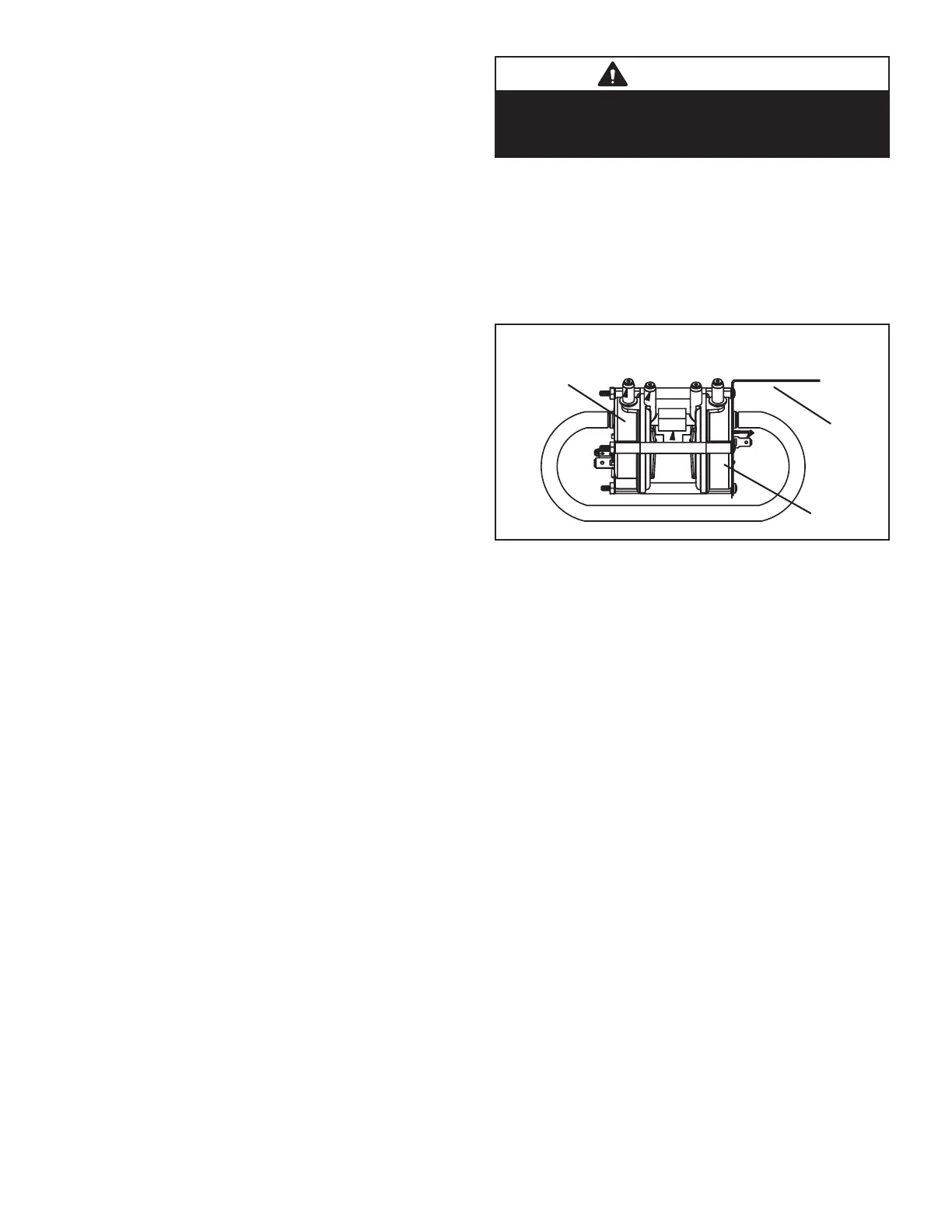

All SLP99UHV units are equipped with a combustion air

inducer (B6) and dual pressure switch assembly (high re

and low re). The pressure switch (FIGURE 17) serves

four functions. First it establishes calibration points for

the vent calibration routine. The combustion air inducer’s

speed at a given ring rate is a function of the vent system

resistance. The calibration routine establishes the inducer

speed required to make low and high re switches for a

given vent pipe installation and interpolates the speeds

required to achieve all intermediate rates between these

two points. The setting for lowre switch on the assembly

is such that it does not normally enter into the vent cali-

bration routine.

Second, the switch proves combustion air inducer oper-

ation by sensing a vacuum energizing the control circuit

and allowing ignition. The low re pressure switch pro-

vides this function.

Third, the switch interrupts the combustion process in the

event vent outlet or combustion air intake blockage. Final-

ly, the switch interrupts the combustion process if the con-

densate drainage system becomes blocked to the point

the condensate level builds up in the cold end header box/

secondary coil or vent system.

If the switch assembly is to be replaced, replace the en-

tire assembly. Individual switch components cannot be

replaced.

Combustion Air Inducer Specications

• Three phase AC induction motor

• Sealed ball bearings

• VFD controlled by the furnace control board

• Operates at 60 to 180Hz

• Voltage range 33 - 110 VAC

• Amp draw 0.75 - 1.0

• Windings resistance 16.74 / 14.26

• Speed range 1000 - 5400 RPM

Combustion Air Inducer Troubleshooting

• Is the CAI mounted correctly?

• Any air or condensate leaks?

• Does the motor and wheel turn freely?

• Any missing or broken mounting screws?

• Perform a visual inspection

• Clean as needed

• Measure the resistance between each of the wind-

ings. All readings should read 16.74 / 14.26 and be

approximately 10% of each other.

• Check each winding to ground to conrm there is

no continuity / not grounded

WARNING

The pressure switch is a safety shut-down control

in the furnace and must not be jumpered for any

reason other than troubleshooting.

Pressure Switch Troubleshooting

To troubleshoot the pressure switch, add a temporary

jumper. The unit will not re with the switch jumpered.

Therefore, the pressure switch must be bypassed after

the combustion air inducer is activated. This will determine

if the pressure switch and furnace are operating properly.

However, this may not indicate if the sealed combustion

system is operating properly.

bracket

low fire

high fire

Pressure Switch (S18)

FIGURE 17

Vent Calibration

The vent calibration sequence establishes furnace oper-

ating parameters in a specic installation. The integrat-

ed control runs the calibration and may be repeated as

necessary to maintain proper furnace operation. Prior to

calibration, all duct work (and returns) vent pipe and con-

densate trap (primed) must be connected.

If calibration is successful the data is stored in memory

and will be used to determine furnace operation and main-

tain parameters during heat call. If calibration is not suc-

cessful, the integrated control will proceed to a 5 minute

delay and signal the appropriate code. After the 5 minute

delay the calibration will be repeated 4 more times with a

5 minute delay in between. If still unsuccessful after the

4 trials (total 5) the integrated control will go into a 1 hour

soft lockout.

Calibration may be initiated by:

• Initial call for heat

• Cycling main power o / on and then call for heat

• Venting conditions change (aecting high and low

pressure switch operation)

• Ramp down low re switch check failed (calibration

will follow next call for heat)

• The service technician (by pressing the push but-

ton found on the integrated control until the control

cycles through to “Field Test Mode”)

Loading...

Loading...