Page 5

TP SERIES

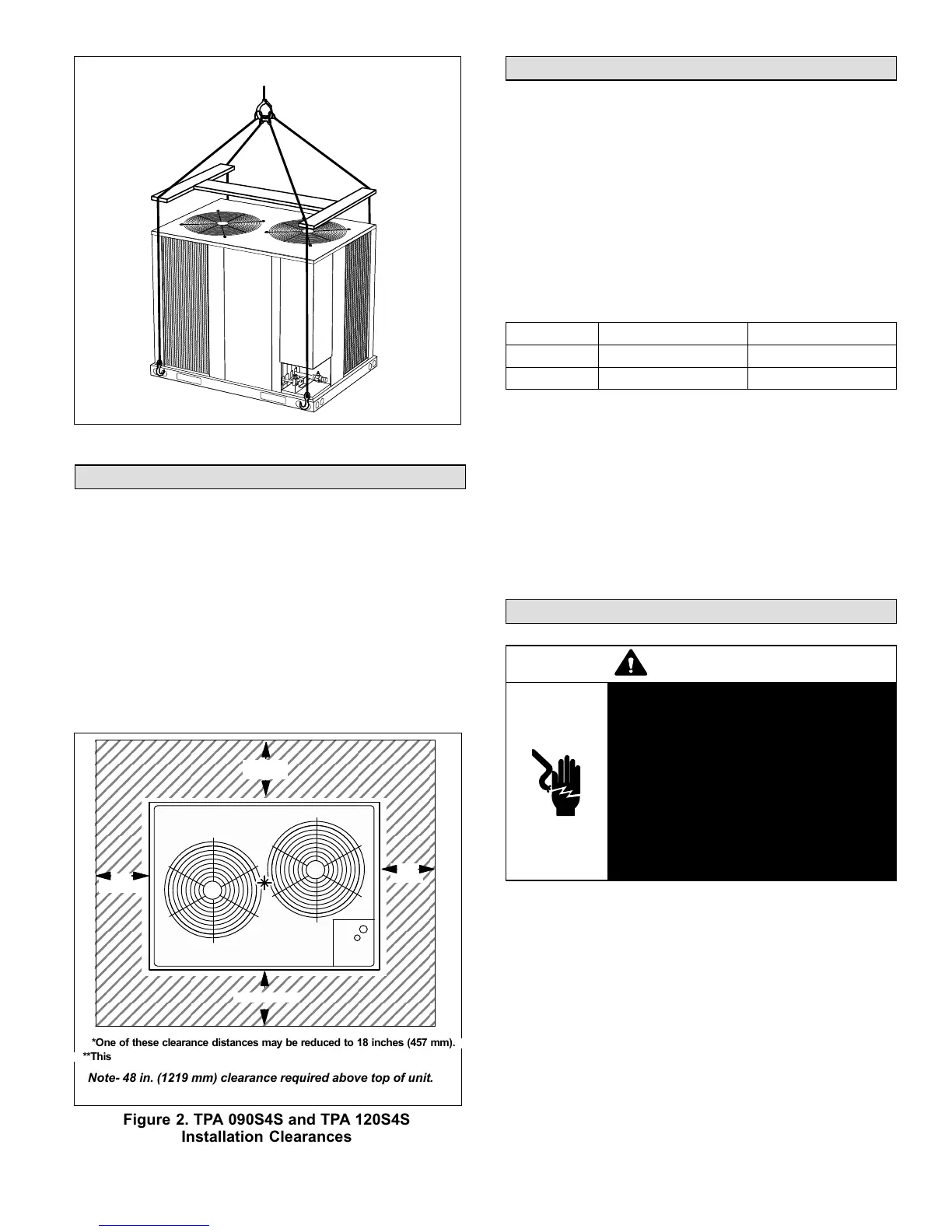

Caution - do not

walk on unit.

Lifting point should be directly above the center of gravity.

Important - all panels

must be in place for

rigging.

Figure 1. TPA 090S4S and TPA 120S4S

Installation Clearances

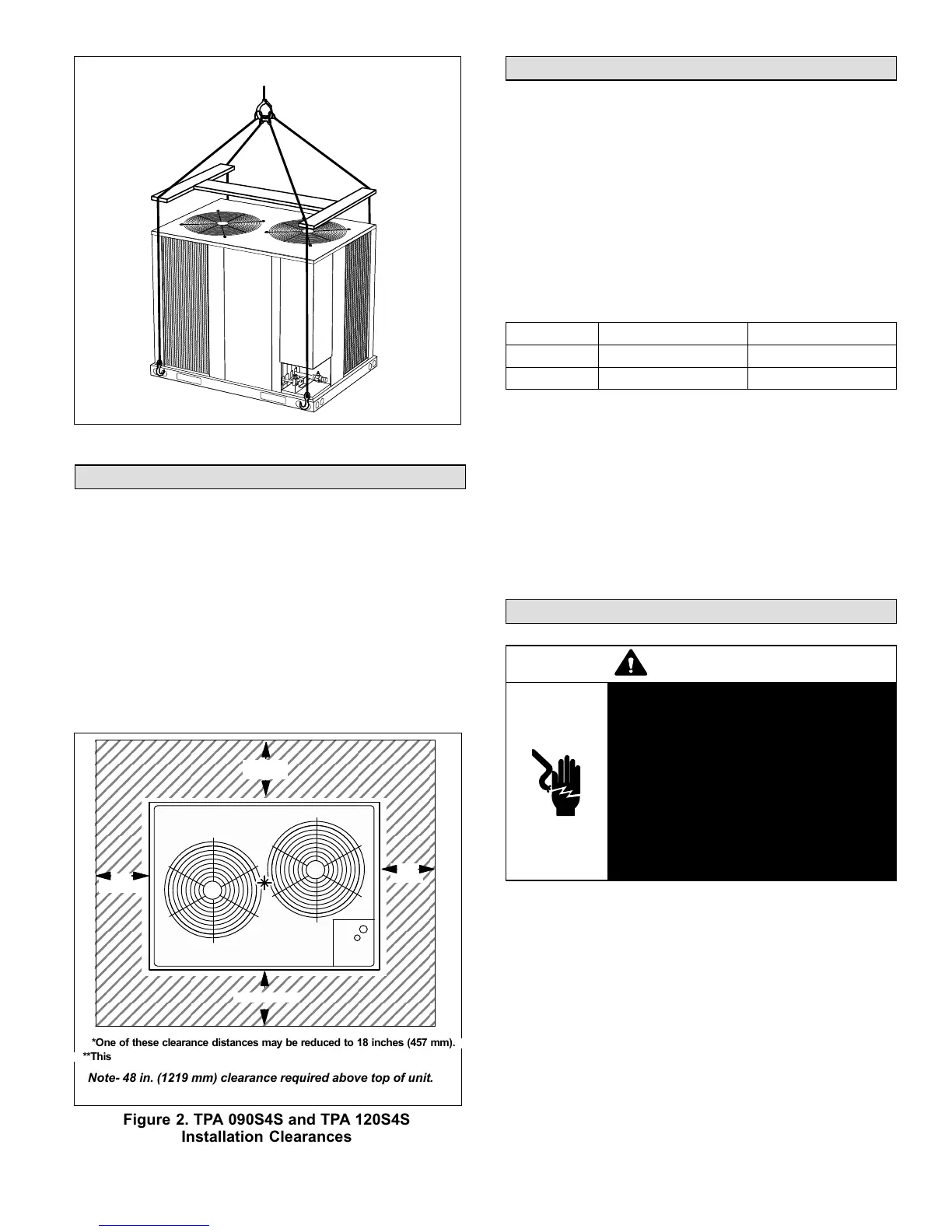

See Unit Dimensions on page to sizing mounting slab,

platforms or supports. Refer to figure 2 for mandatory

installation clearance requirements.

NOTES:

Clearance to one of the remaining two sides may be

12 in. (305 mm) and the final side may be 6 in. (152

mm).

A clearance of 24 in. (610 mm) must be maintained

between two units.

48 in. (1219 mm) clearance required on top of unit.

ÏÏÏÏÏÏÏÏÏÏÏÏÏÏÏ

ÏÏÏÏÏÏÏÏÏÏÏÏÏÏÏ

ÏÏÏÏÏÏÏÏÏÏÏÏÏÏÏ

ÏÏÏÏÏÏÏÏÏÏÏÏÏÏÏ

ÏÏÏÏÏÏÏÏÏÏÏÏÏÏÏ

ÏÏÏÏÏÏÏÏÏÏÏÏÏÏÏ

ÏÏÏÏÏÏÏÏÏÏÏÏÏÏÏ

ÏÏÏÏÏÏÏÏÏÏÏÏÏÏÏ

ÏÏÏÏÏÏÏÏÏÏÏÏÏÏÏ

ÏÏÏÏÏÏÏÏÏÏÏÏÏÏÏ

ÏÏÏÏÏÏÏÏÏÏÏÏÏÏÏ

ÏÏÏÏÏÏÏÏÏÏÏÏÏÏÏ

ÏÏÏÏÏÏÏÏÏÏÏÏÏÏÏ

Note- 48 in. (1219 mm) clearance required above top of unit.

Figure 2. TPA 090S4S and TPA 120S4S

Installation Clearances

*One of these clearance distances may be reduced to 18 inches (457 mm).

**This clearance may be reduced to 12 inches (305 mm).

SEE

NOTES

36 (914)

30

(762)

SEE

NOTES

Line Set

Field refrigerant piping consists of liquid and suction lines

connecting the condensing unit and the indoor unit. Liquid

and suction service valves are located in a compartment at

the corner of the unit below the control box. Piping can be

routed directly from the service valves or field supplied

elbows can be added to divert the piping as required

Refer to table 1 for field-fabricated refrigerant line sizes for

runs up to 50 linear feet (15 m).

Table 1. Refrigerant Line Sizes for Runs

Up to 50 Linear Feet

Unit Liquid Line Suction Line

TPA 090 5/8” (16 mm) 1-3/8” (35 mm)

TPA 120 5/8” (16 mm) 1-3/8” (35 mm)

Refrigerant Line Limitations

You may install the unit in applications that have line set

lengths of up to 50 linear feet (15 m) with refrigerant line

sizes as outlined in table 1 (excluding equivalent length of

fittings). Size refrigerant lines greater than 50 linear feet

(15m or greater) according to the Lennox Refrigerant

Piping Design and Fabrication Guidelines (Corp. 9351-L9)

or latest version.

Electrical Connections

WARNING

Electric Shock Hazard. Can cause injury

or death.

Line voltage is present at all components

on units with single‐pole contactors, even

when unit is not in operation!

Unit may have multiple power supplies.

Disconnect all remote electric power

supplies before opening access panel.

Unit must be grounded in accordance

with national and local codes.

In the United States, wiring must conform with current local

codes and the current National Electric Code (NEC). In

Canada, wiring must conform with current local codes and

the current Canadian Electrical Code (CEC).

TRANSFORMER - 24VAC, 70VA - PROVIDED

NOTE — The addition of accessories to the system could

exceed the 70VA power requirement of the

factory‐provided transformer. Measure the system's

current and voltage after installation is complete to

determine transformer loading. If loading exceeds the

factory‐provided transformer capacity, a larger

field‐provided transformer will need to be installed in the

system.

Loading...

Loading...