Page 9

C − Drier

A filter drier designed for all XC16 model units is factory

installed in the liquid line. The filter drier is designed to re-

move moisture and foreign matter, which can lead to com-

pressor failure.

Moisture and / or Acid Check

Because POE oils absorb moisture, the dryness of the

system must be verified any time the refrigerant system

is exposed to open air. A compressor oil sample must be

taken to determine if excessive moisture has been

introduced to the oil. Table 2 lists kits available from Lennox

to check POE oils.

If oil sample taken from a system that has been exposed to

open air does not test in the dry color range, the filter drier

MUST be replaced.

IMPORTANT

Replacement filter drier MUST be approved for

R−410A refrigerant and POE application.

Foreign Matter Check

It is recommended that a liquid line filter drier be replaced

when the pressure drop across the filter drier is greater than

4 psig.

TABLE 2

KIT CONTENTS TUBE SHELF LIFE

10N46 − Refrigerant Analysis Checkmate−RT700

10N45 − Acid Test Tubes Checkmate−RT750A (three pack)

2 − 3 years @ room temperature. 3+

years refrigerated

10N44 − Moisture Test Tubes

Checkmate − RT751 Tubes (three

pack)

6 − 12 months @ room temperature. 2

years refrigerated

74N40 − Easy Oil Test Tubes

Checkmate − RT752C Tubes (three

pack)

2 − 3 years @ room temperature. 3+

years refrigerated

74N39 − Acid Test Kit Sporlan One Shot − TA−1

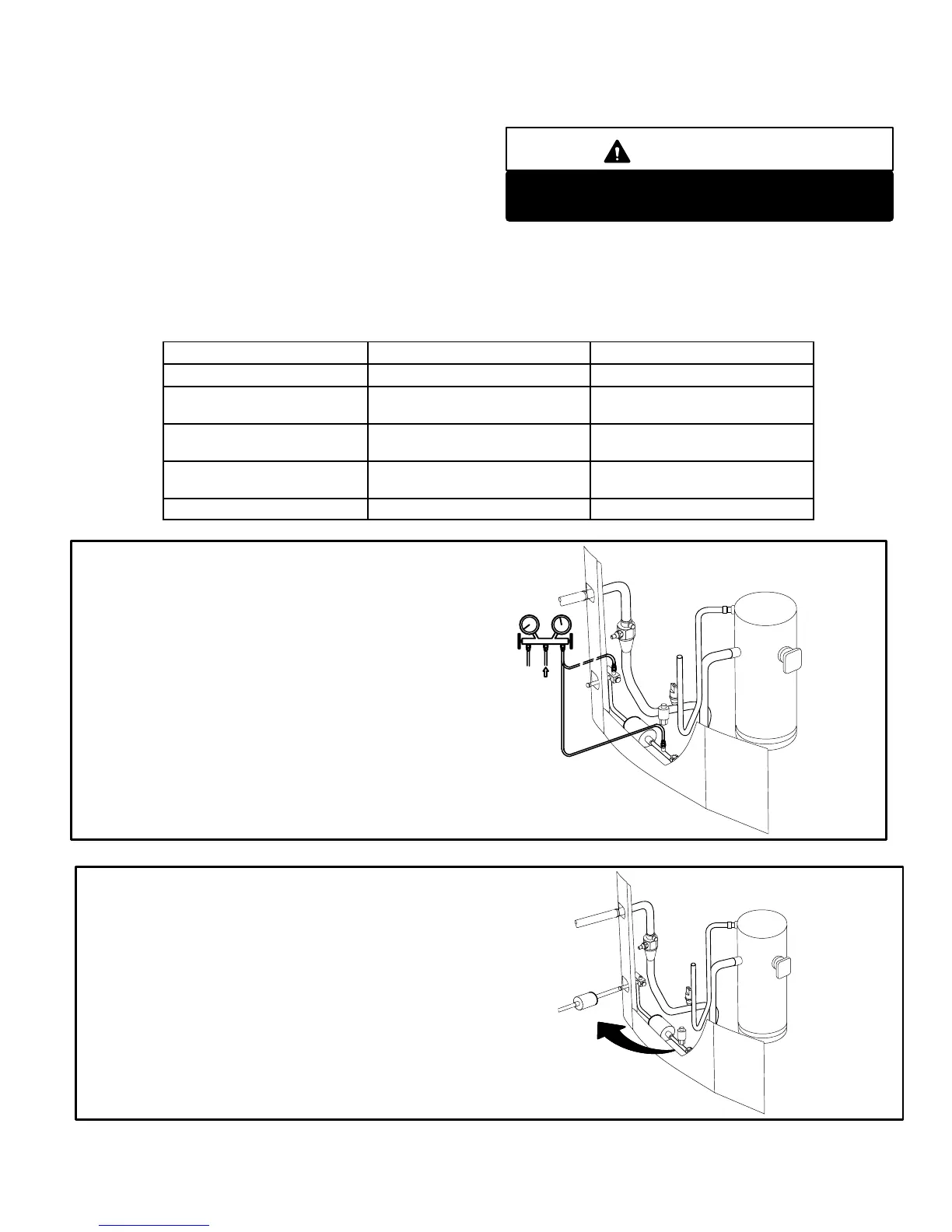

FIGURE 9

1− Shut off power to unit.

2− Remove high pressure switch from fitting next to filter drier.

(A schrader core is located under the high pressure switch).

3− Install high pressure gauge hose onto high pressure switch fitting.

4− Turn power on to unit and turn room thermostat to call for cooling.

5− Record pressure reading on gauge.

6− Remove hose from high pressure fitting and install on liquid line valve.

7− Read liquid line valve pressure.

8− High pressure fitting pressure − liquid line valve pressure = filter drier

pressure drop.

9− If pressure drop is greater than 4 psig replace filter drier. See figure 10.

10− Re−install high pressure switch.

MEASURING FILTER DRIER PRESSURE DROP

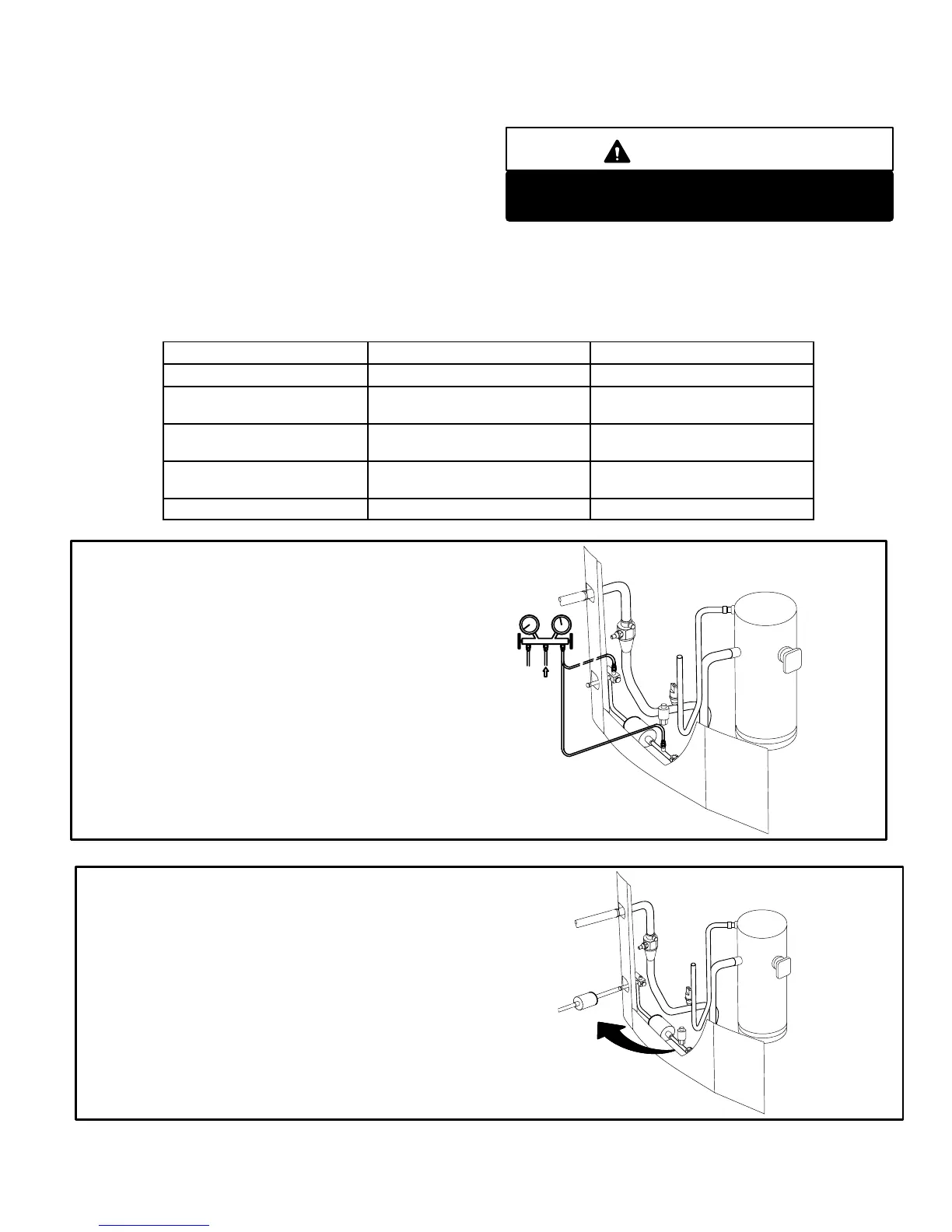

FIGURE 10

REPLACING FILTER DRIER

1− Recover all refrigerant from unit.

2− Remove original filter drier.

3− Install new filter drier in existing location or alternate location as

shown. Proper brazing procedures should be followed.

4− Evacuate system. See section IV − part B − .

5− Recharge system. See section IV − part C − .

Loading...

Loading...