Page 10

Replacement

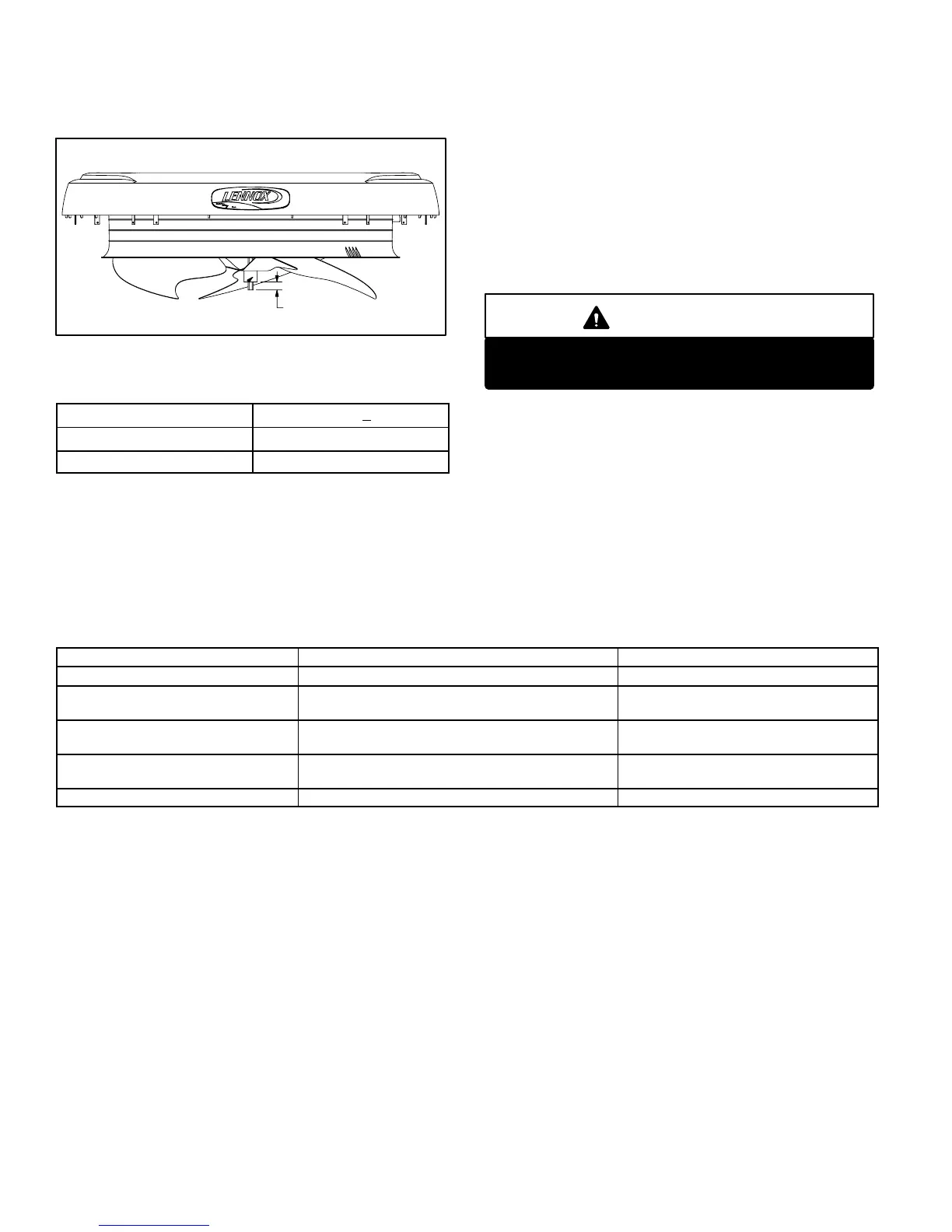

See figure 13 if condenser fan motor replacement is nec-

essary.

FIGURE 13

A" See Table 2

TABLE 2

XP19 UNIT "A" DIM. + 1/8"

−024, −036 3/4"

−048, −060 Flush

G−Filter Drier

A filter drier designed for all XP19 model units is factory

installed in the liquid line. The filter drier is designed to re-

move moisture and foreign matter, which can lead to com-

pressor failure.

Moisture and / or Acid Check

Because POE oils absorb moisture, the dryness of the

system must be verified any time the refrigerant sys-

tem is exposed to open air. A compressor oil sample

must be taken to determine if excessive moisture has been

introduced to the oil. Table 3 lists kits available from Lennox

to check POE oils.

If oil sample taken from a system that has been exposed to

open air does not test in the dry color range, the filter drier

MUST be replaced.

IMPORTANT

Replacement filter drier MUST be approved for

R410A refrigerant and POE application.

Foreign Matter Check

It is recommended that a liquid line filter drier be replaced

when the pressure drop across the filter drier is greater

than 4 psig.

H−Accumulator (XP19−060−1 and −2 only)

5 ton XP19−1 and −2 units are equipped with an accumula-

tor. The purpose of the accumulator is to trap and evapo-

rate all liquid refrigerant returning to the compressor.

TABLE 3

KIT CONTENTS TUBE SHELF LIFE

10N46 − Refrigerant Analysis Checkmate−RT700

10N45 − Acid Test Tubes Checkmate−RT750A (three pack)

2 − 3 years @ room temperature. 3+ years

refrigerated

10N44 − Moisture Test Tubes Checkmate − RT751 Tubes (three pack)

6 − 12 months @ room temperature. 2 years

refrigerated

74N40 − Easy Oil Test Tubes Checkmate − RT752C Tubes (three pack)

2 − 3 years @ room temperature. 3+ years

refrigerated

74N39 − Acid Test Kit Sporlan One Shot − TA−1

Loading...

Loading...