Page 7

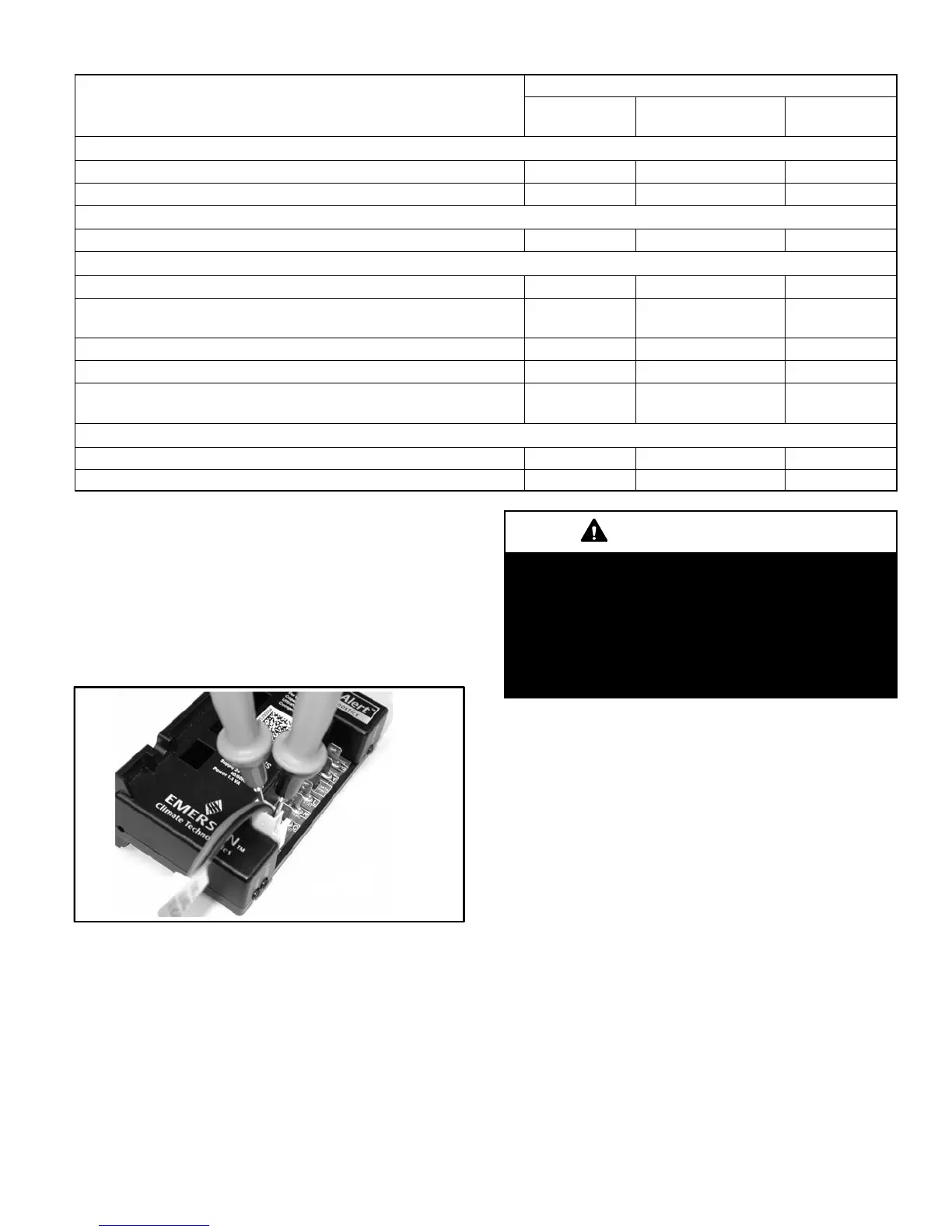

TABLE 1

Compressor Operation

Unit Readings

Y1 −

1st-Stage

Expected Results

Y2 −

2nd-Stage

Compressor

Voltage Same

Amperage Higher

Condenser Fan motor

Amperage Same or Higher

Temperature

Ambient Same

Outdoor Coil Discharge Air Higher in Cooling

Lower in Heating

Compressor Discharge Line Higher

Indoor Return Air Same

Indoor Coil Discharge Air Lower in Cooling

Higher in Heating

Pressures

Suction (Vapor) Lower

Liquid Higher

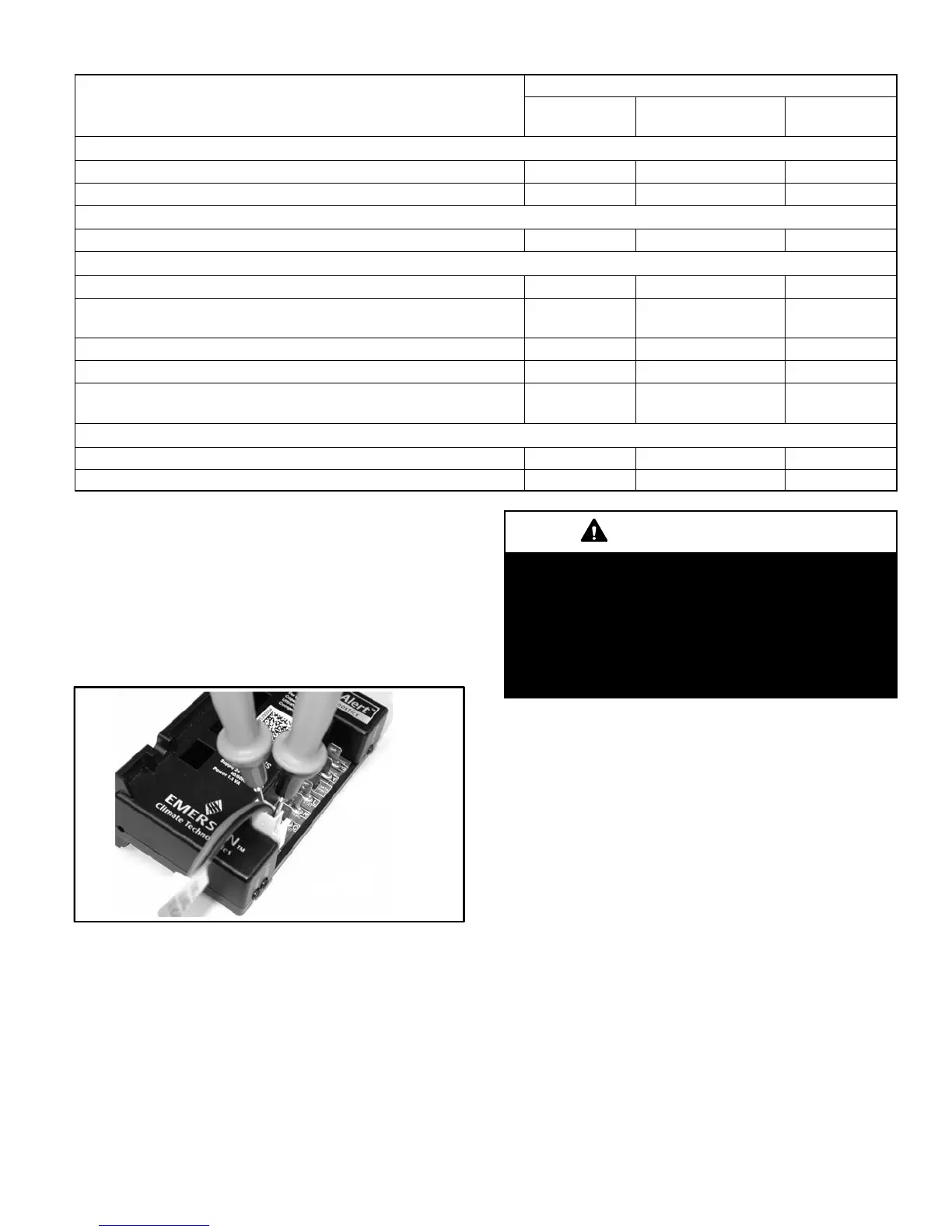

STEP 2 Confirm DC voltage output on compressor

solenoid plug

1−. Shut power off to the outdoor unit.

2−. Insert lead wires from voltmeter into back of the red

and black wire plug jack that feeds power to compres-

sor solenoid coil. Set voltmeter to DC volt scale to read

DC voltage output from LSOM II plug. See figure 9.

FIGURE 9

3−. Apply a Y1 and Y2 demand from the indoor thermostat

to the LSOM II.

4−. Turn power back on to unit.

5−. Compressor should cycle ON" when Y1 is calling.

6−. With Y2 calling, 5 seconds after compressor cycles

ON", LSOM II will output 24 volt DC signal to the com-

pressor solenoid plug. Once the solenoid has pulled in,

the LSOM II will reduce the DC voltage to a pulsating

6 to 18 volt DC output to the solenoid to allow the sole-

noid to remain energized.

IMPORTANT

When checking compressor for two−stage operation,

always cycle Y1 to Y2 from terminals on the LSOMII

or room thermostat connections. DO NOT cycle sec-

ond stage (Y2) of compressor by unplugging the

24VDC solenoid LSOM II end of plug. The LSOM II will

only output a 6 to 18VDC signal which will be insuffi-

cient voltage to pull the solenoid coil in for second

stage.

If compressor solenoid is still not shifting to high capac-

ity, this check will verify that DC power is being fed from

the LSOM II.

7−. Shut power off to unit (main and low voltage)

8−. Unplug the 2 pin solenoid plug from the fusite connec-

tion on the compressor and the plug end from the

LSOM II.

9−. Using an OHM meter, check for continuity on the plug

harness wire ends (red to red, black to black). Wires

should have continuity between same colors and no

continuity between opposite color wires.

If the above checks verify that the solenoid plug is pro-

viding power to cycle into high capacity operation, con-

tinue to step 3 to determine if problem is with solenoid

coil in compressor

STEP 3 Confirm internal unloader solenoid has

proper resistance

1−. Shut all power off to unit (main and low voltage)

2−. Unplug the molded plug from the compressor solenoid

2−pin fusite.

3−. Using a volt meter set on the 200 ohm scale

Replace the Compressor under these conditions:

Loading...

Loading...