System bus (CAN) with Ser vo PLC & Drive PLC

General information

2-9

l PLC-Systembus EN 1.1

2.6 Transmitting parameter data

With Lenze devices ”codes” are parameter data.

• Parameter data are, for instance, set when the plant settings are made during commissioning

or when the material for the production machine is changed.

• Parameter data are transmitted as so-called SDOs (

Service Data Objects

) via the system bus

and acknowledged by the recipient, i.e. the transmitter receives a message whether the

transmission was successful.

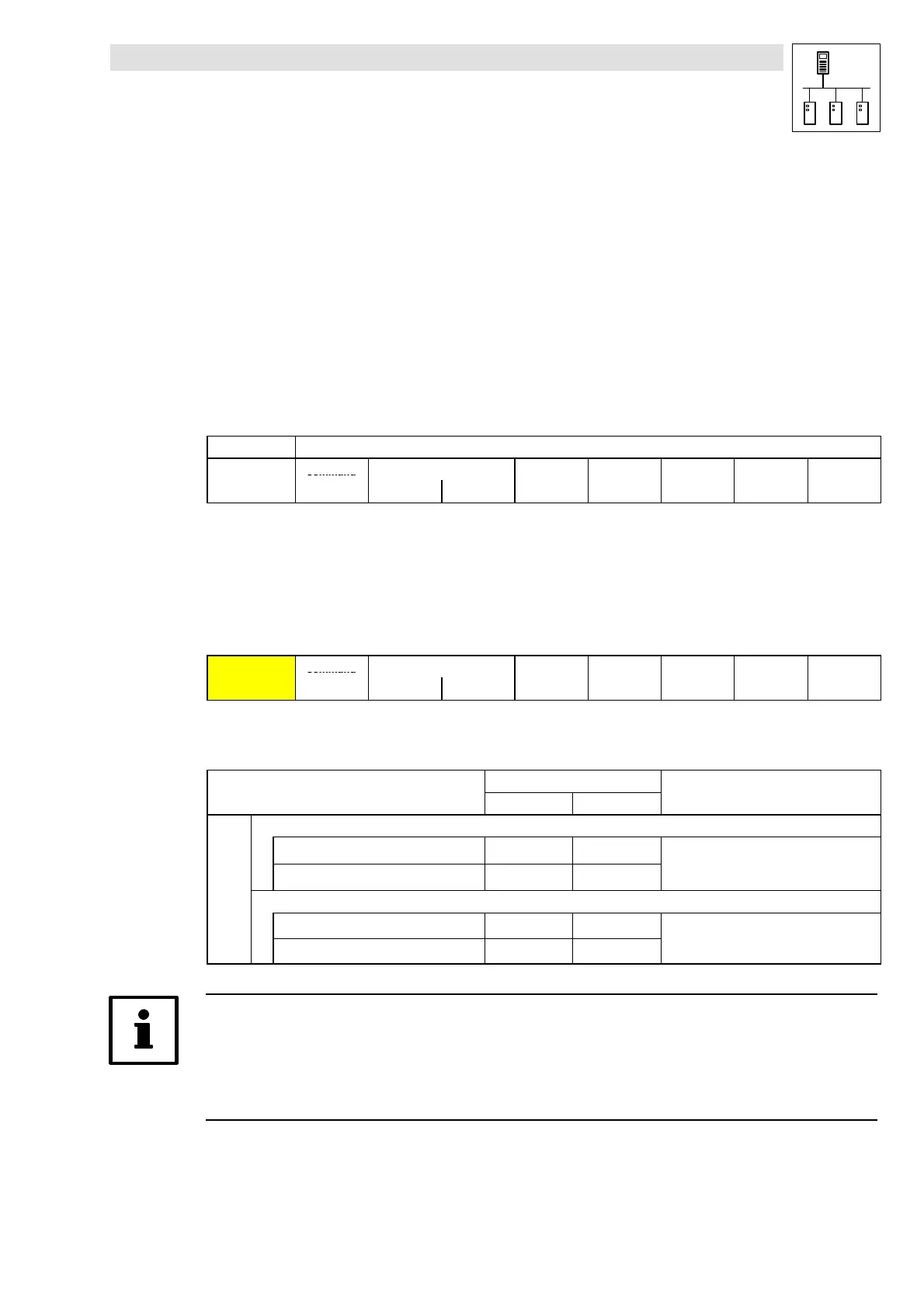

2.6.1 Telegram structure

Structure of the telegram for parameter data:

11 Bit 8-byte user data

Command

Index

ent

er

code

Low-byte High-byte

u

n

e

ata

ata

ata

ata

• In the below sub-sections, the individual telegram components are explained in detail.

• In chapter 2.6.2 you can find an example of writing a parameter. (^ 2-13)

• In chapter 2.6.3 you can find an example of reading a parameter. (^ 2-14)

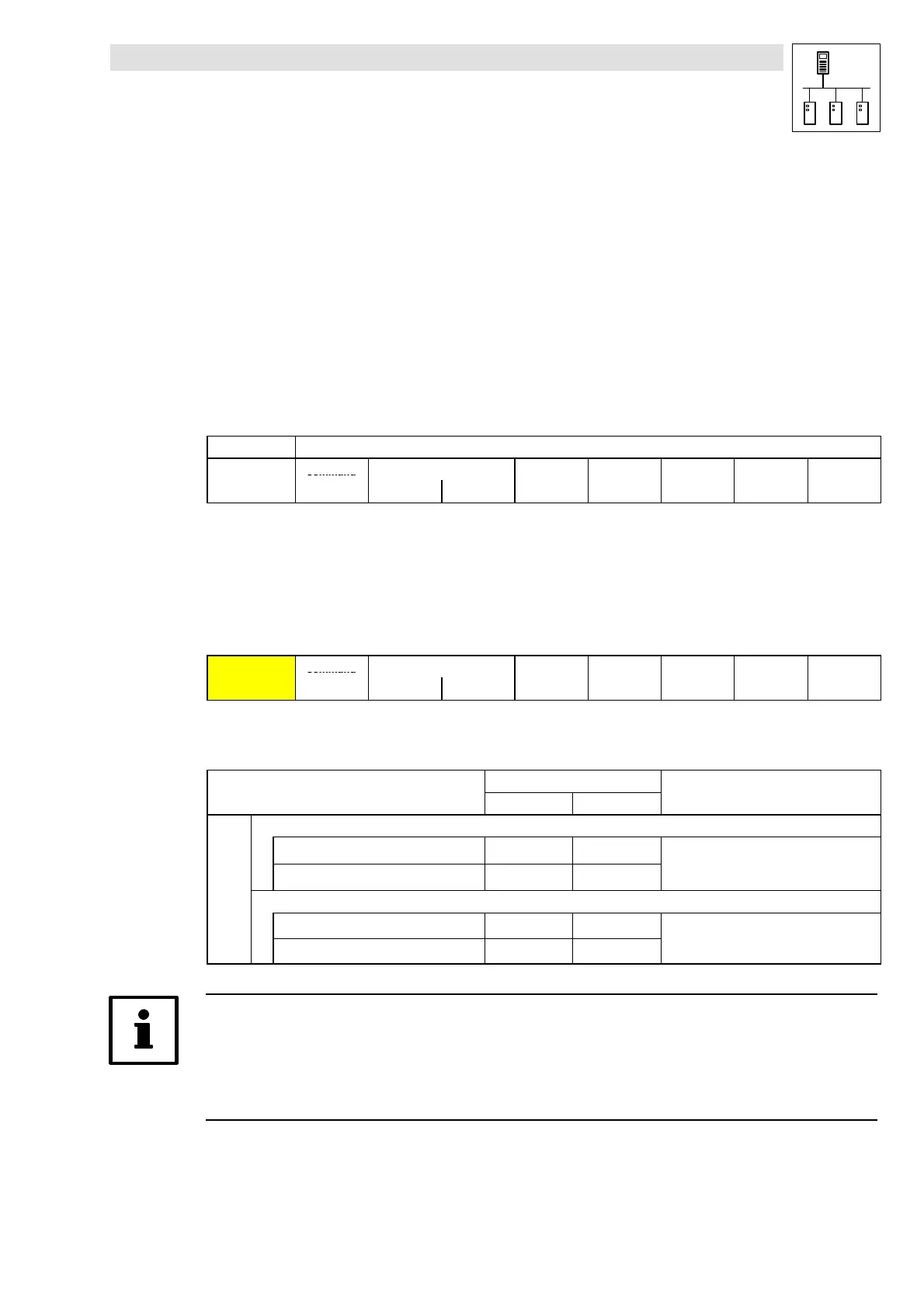

2.6.1.1 Identifier

Command

Index

ent

er

code

Low-byte High-byte

u

n

e

ata

ata

ata

ata

Two parameter channels are available for parameter data transmission. They are addressed via the

identifier.

Identifier = Basic identifier + node address of the participant

dec hex

SDOs Parameter channel 1

Output (transmit) 1536 600

+ C0350

(CAN)

Input (receive) 1408 580

+

5

+ C2450

(FIF CAN)

Parameter channel 2

Output (transmit) 1600 640

+ C0350

(CAN)

Input (receive) 1472 5C0

+

5

+ C2450

(FIF CAN)

Tip!

There is an offset of 64 between the identifiers for parameter channels 1 and 2:

• Output parameter channel 1 = 1536

• Output parameter channel 2 = 1536 + 64 = 1600

Loading...

Loading...