Application examples

15-4

SHB9300CRV EN 2.0

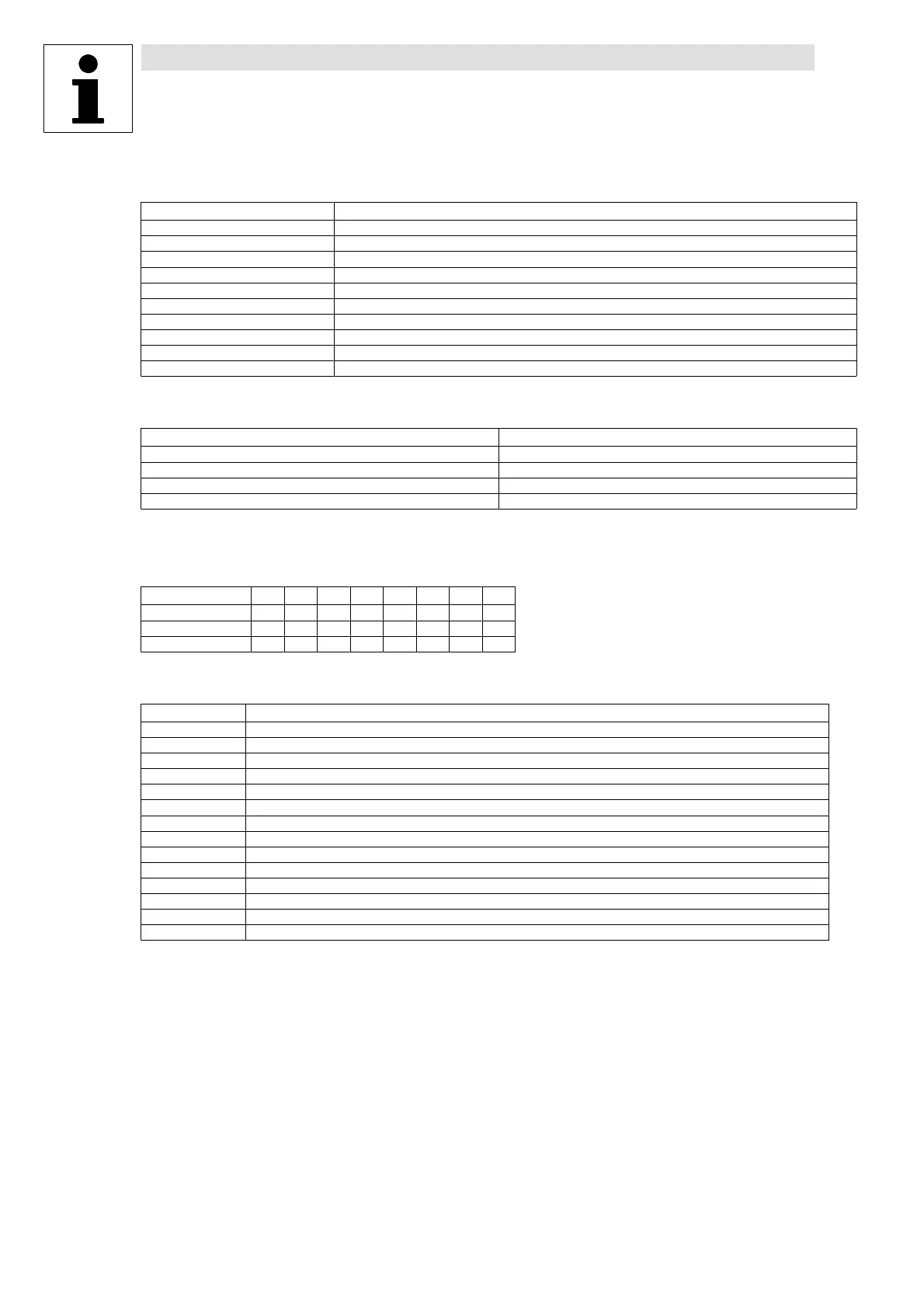

Digital signals

Terminal Function

X5, terminal 28 Controller enable

X5, E1 Selection of event profile (C1420)

X5, E2 Profile selection (see table terminal layout)

X5, E3 Profile selection (see table terminal layout)

X5, E4 Profile selection (see table terminal layout)

X5, E5 Fault reset (trip reset) / profile acceptance

X5, A1 Fault (trip)

X5, A2 Contouring error limit reached

X5, A3 Ready for operation (RDY)

X5, A4 Welding time error

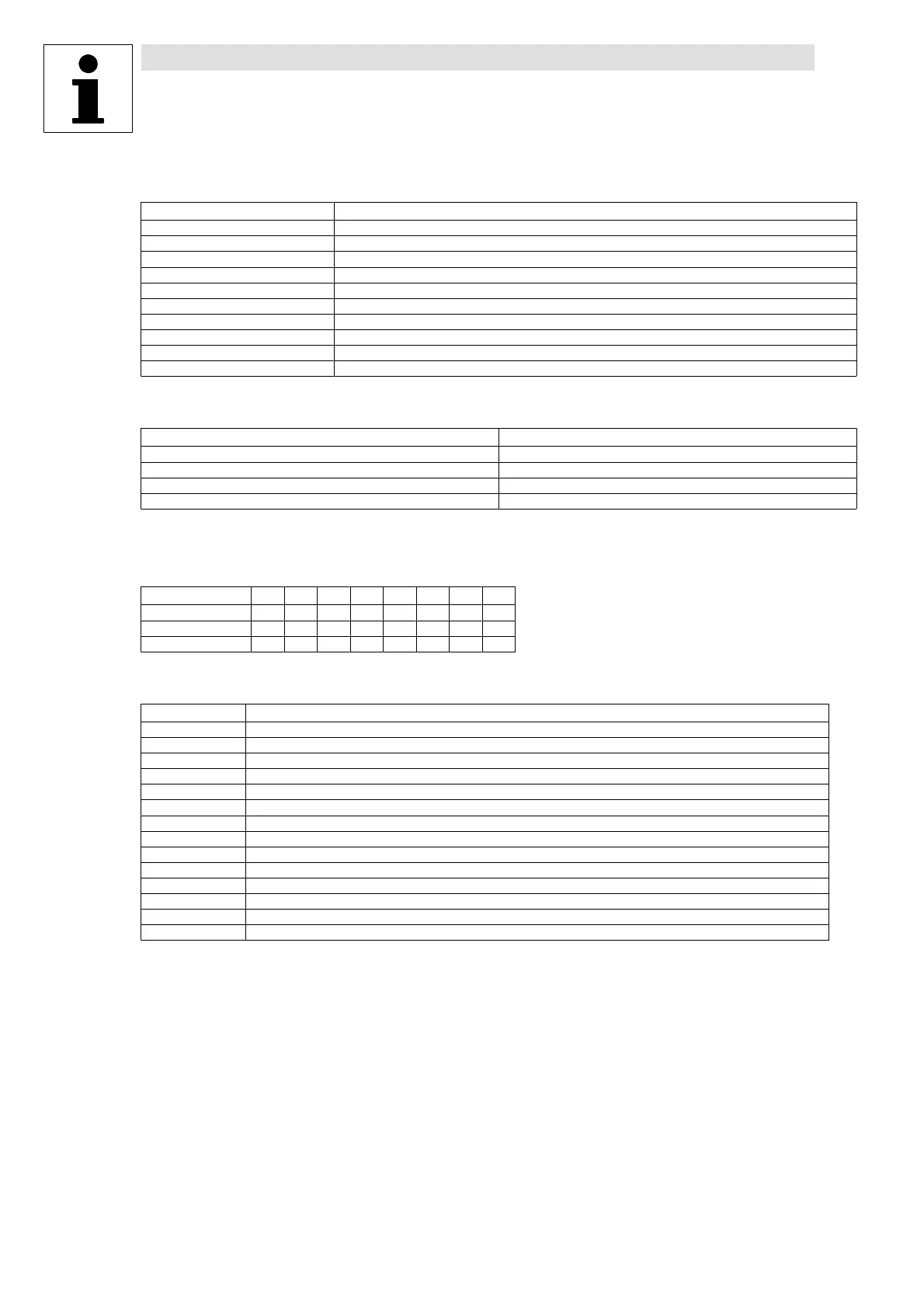

Analog signals

Terminal Function

Analog input 1: X6, terminals 1, 2 Setpoint of the virtual master

Analog input 2: X6, terminals 3, 4 not assigned

Analog output 1: X6, terminal 62 Act. speed

Analog output 2: X6, terminal 63 Act. torque

Digital frequency output: X10: Virtual master value

Terminal layout for profile selection

Profile no. 0 1 2 3 4 5 6 7

X5, E2 0 1 0 1 0 1 0 1

X5, E3 0 0 1 1 0 0 1 1

X5, E4 0 0 0 0 1 1 1 1

Application-specific codes

Code Function

C1420 Selection of the event profile (dig. input E1 = H)

C1380/1 Hysteresis of contouring error evaluation

C1380/2 Hysteresis of contouring error warning

C0250 Activation of the master value reduction (C0250=1 => reduction value C0472/7 active)

0472/1 Stretching/compression of X-axis (100% = no stretching/compression)

0472/2 Influence of speed precontrol

0472/3 Influence of torque precontrol

0472/4 Reduction factor for contouring error warning (warning limit = C0472/4 x C1477/2)

0472/7 Reduced master value

0472/10 Torque limit value

0474/1 Welding time (1 incr. = 1 ms)

1476/1 Phase trimming in X-direction

1476/16 Touch-probe position in X-direction

1477/2 Contouring error limit (in s_units)

Loading...

Loading...