Maintenance

Maintenance operations

7

42

Lenze ¯ MA 12.0013 ¯ 3.0

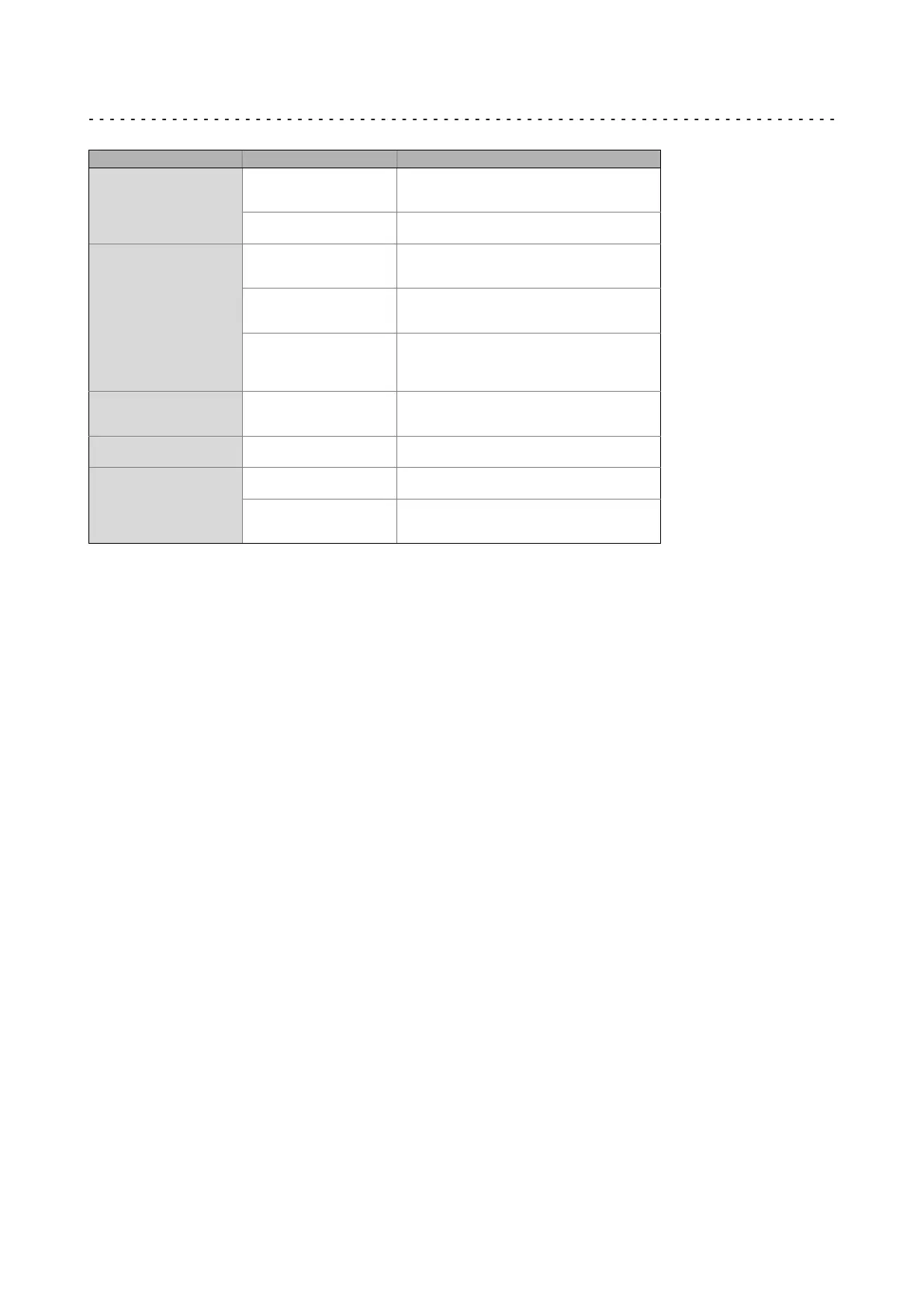

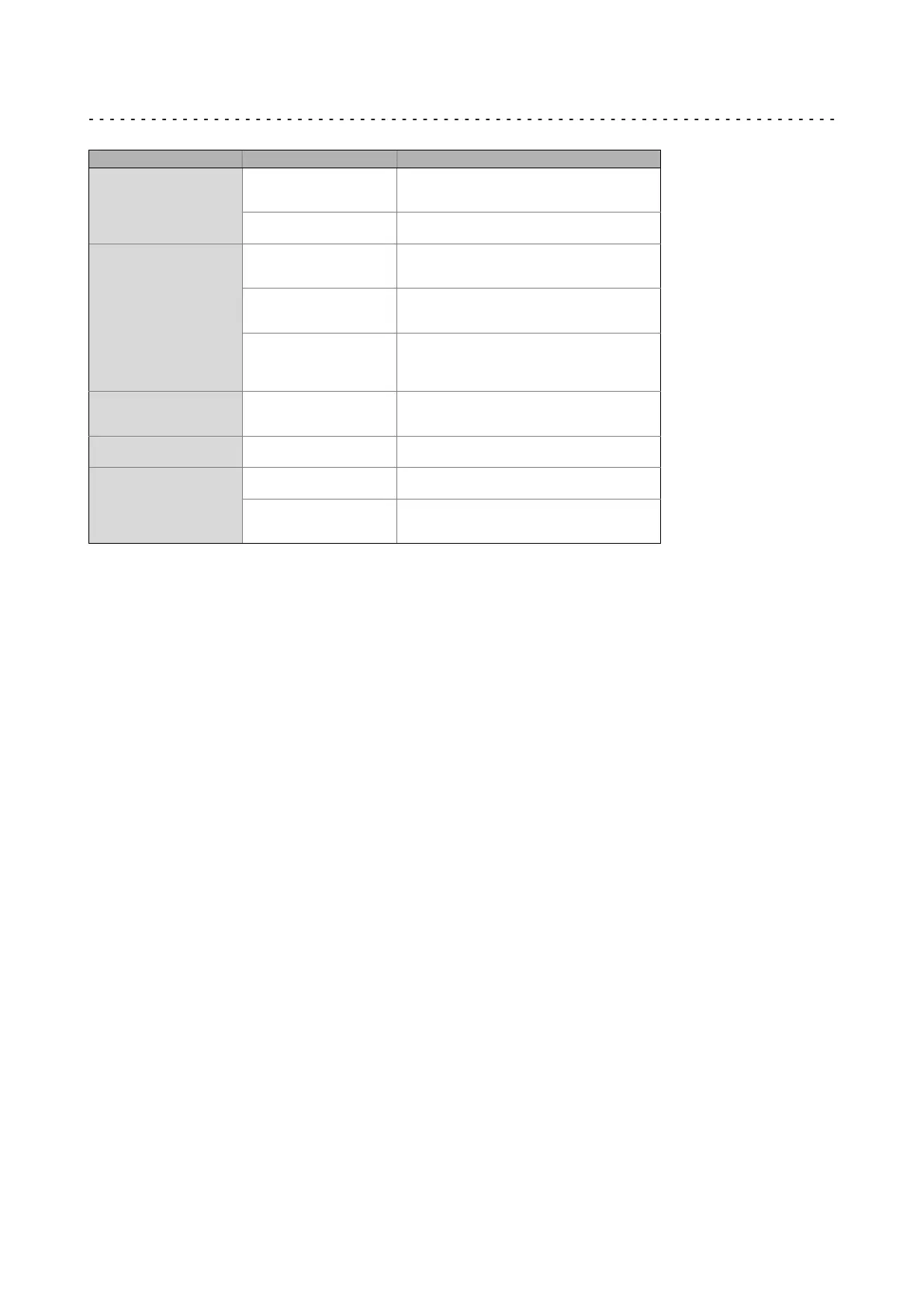

Time interval Measures Description of the operations

On the first day, then every

month

Visual inspection Inspection regarding unusual operating noises,

vibrations and impermissibly high

temperatures

Leakage test If leakages are found, eliminate their cause, see

"Troubleshooting" section

Every 6 months

Clean gearbox Remove dirt and dust deposits. To be inspected

more frequently in the case of heavy dirt

accumulation

Check rubber buffer Check rubber buffer of the torque plate and

replace it in the event of visible wear or

damage

Relubricate bell housings

of the roller bearing

For bell housings with lubricating nipples:

relubricate roller bearing in bell housing using a

grease gun. Grease: Klüber Microlube GLY 92,

quantity approx. 5 grams

Annually Check vent valve Check whether air can pass through the

breather element. If it shows blockages, replace

it

After 3h, then every 2 years Check fastening elements Check mounting of the gearbox (foot, flange

and shrink disk mounting).

According to diagram; at

the latest as specified in

the lubricant table

Oil change Carry out oil change 54 for type and amount

of lubricant see nameplate

Replace roller bearing

grease filling

When an oil change is carried out, the roller

bearing grease filling should also be replaced

55

7.3 Maintenance operations

Gearboxes and geared motors are ready to use on delivery and filled by Lenze with the

lubricant type and lubricant quantity indicated on the nameplate. The first filling

corresponds to the mounting position and design indicated on the nameplate.

Loading...

Loading...