Maintenance

Maintenance operations

Replacing the lubricant

8

61

Lenze • BA 12.0023 • 9.0

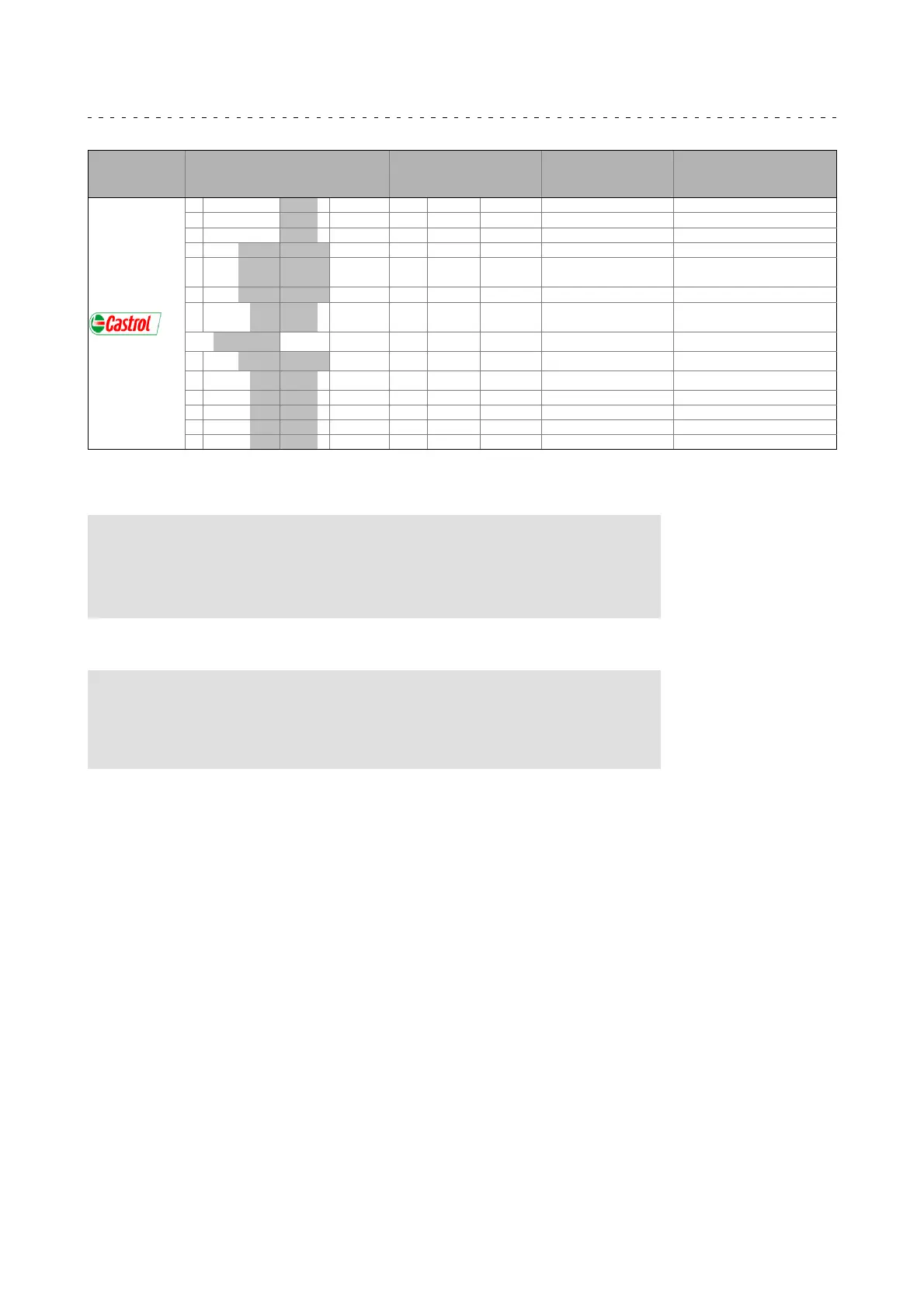

Gearbox type

GSS

GKK07

Gearbox type

GKL, GST, GFL, GKS,

GKR, GKK04 ... 06

DIN 51517-3: CLP

ISO 12925-1: CKC/CKD

Ambient temperature [°C]

-50 0 +50

0 +40 CLP VG 460 Alpha SP 460

0 +40 CLP VG 460 Optigear BM 460

0 +40 CLP VG 460 Tribol 1100/460

-25 +50

3)

CLP HC VG 320 Alphasyn EP 320

-25 +50

3)

CLP HC VG 320

Optigear Synthetic

A 320

-25 +50

3)

CLP HC VG 320 Tribol 1510/320

-20 +40

CLP E VG 320

Tribol Bio Top

1418/320

-40 0

4)

CLP HC VG 46 Optileb HY 46

-25 +50

3)

CLP HC VG 320 Optileb GT 220

-20 +40

CLP VG 220 Food Proof 1810/220

-20 +40 CLP PG VG 220 Tribol 800/220

1) 2)

-20 +40 CLP PG VG 460 Tribol 800/460

1) 2)

-20 +40 CLP PG VG 220 Alphasyn PG 220

1) 2)

-20 +40 CLP PG VG 460 Alphasyn PG 460

1) 2)

8.2.4 Replacing the lubricant

Stop!

• Gearbox should be warm.

• Secure drive system and machine from inadvertent movement and

mains connection.

Stop!

With gearbox types GST-3, GFL-3, GSS-3 and GKS-4, the

pre-stage is separately lubricated–all gearbox components have to be

completely drained!

Tip!

When changing the lubricant, also change the grease packing of the

bearings and replace the rotary shaft seals!

1. Place receptacle under oil drain plug.

2. Remove breathing / oil filler plug.

3. Completely drain lubricant by removing the oil drain plug.

4. Reinsert drain plug (if necessary, replace seal).

5. Fill in lubricant through filler hole (quantities see nameplate).

6. Screw in breathing / oil filler plug.

7. Dispose of waste oil according to the applicable regulations.

Loading...

Loading...