6

OCEAN EVO™

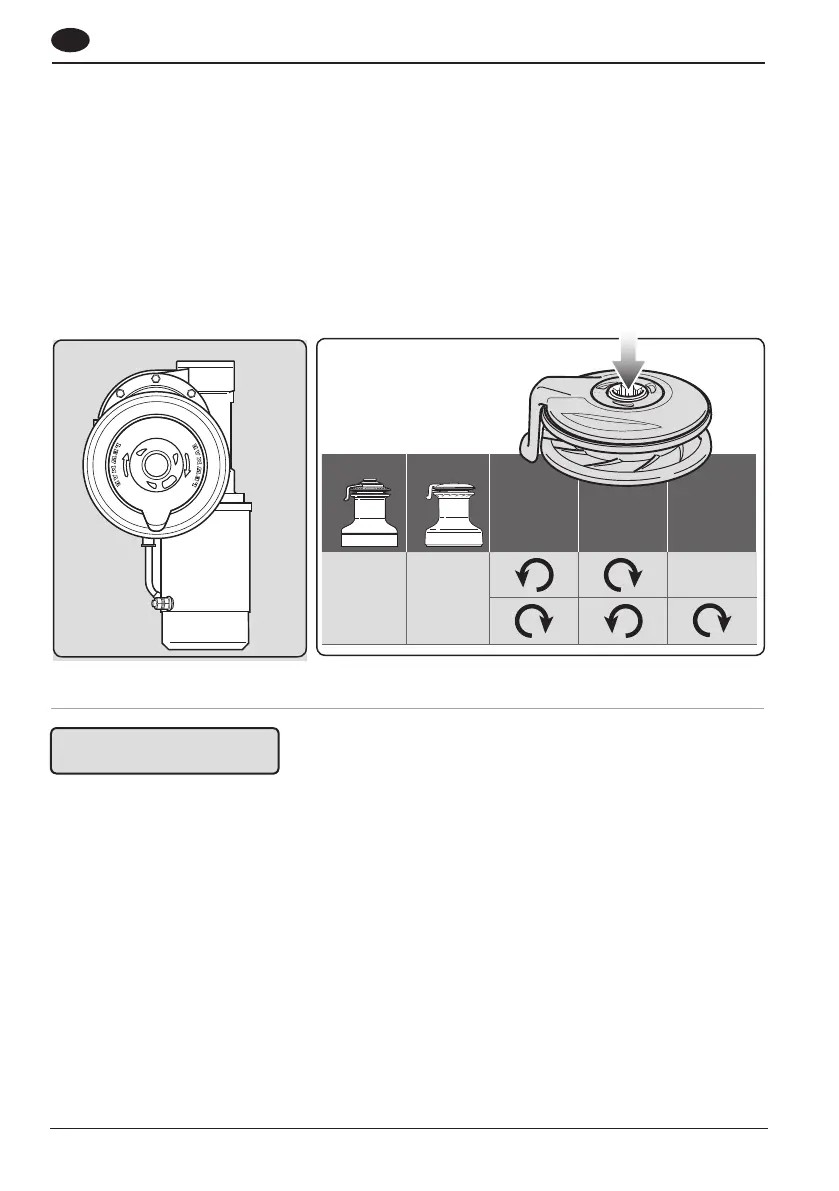

1st 2nd 3rd

68-111 70-90

3.4-43.4-3

GB

3. If the motor/gearbox is fitted the opposite way round it will produce the following problems:

• On a single speed winch it will not operate and make a clicking noise. Remove motor/gearbox and refit the

opposite way round.

• On a 2 or 3 speed winch it will dramatically reduce performance. Contact Lewmar for correct fitting of

electrical connections to rectify this situation or refit the motor/gearbox the opposite way round.

4. Correct spindle rotation when fitted and operated.

• Check clearance below deck and accessibility then position the deck switches near and in view of the

winch. Use template as a guide to cut/drill hole, fit switch and seal.

• Once you have selected the ideal position for winch, motor/gearbox and controls, double check everything

and only then drill holes in the deck.

NOTE: Illustrations based on Model 50 Ocean winch unless stated otherwise. For winch models over 65 just

removing the drum gives access to fixing bolt holes.

• Place the winch in position to ensure correct fit once the holes have been drilled/cut.

1. Unscrew the top cap anti-clockwise and remove.

2. OCEAN 40- Remove feeder arm and collets.

OCEAN 46-111- Remove feeder arm.

3. EVO®- Rotate the drum until the cutout in the upper crown is opposite the collets.

3.5 Fitting an electric/hydraulic winch 40-65

WARNING! Isolate the winch

using circuit breaker/isolator.

Loading...

Loading...