3

300 mm

(12”)

25-30 mm

1” - 1 ³/₁₆”

4

2

1

S900/S2000 windlass ref B10500 iss.1 | 5

4- Installation

4.2 Accessories

Use only genuine Lewmar parts and accessories to ensure top performance and eliminate the risk of voiding your

warranty. For replacement parts, please visit your dealer or www.lewmar.com

4.3 Bulkhead preparation

IMPORTANT - Plan location carefully at the stern of the vessel and allow for the following:

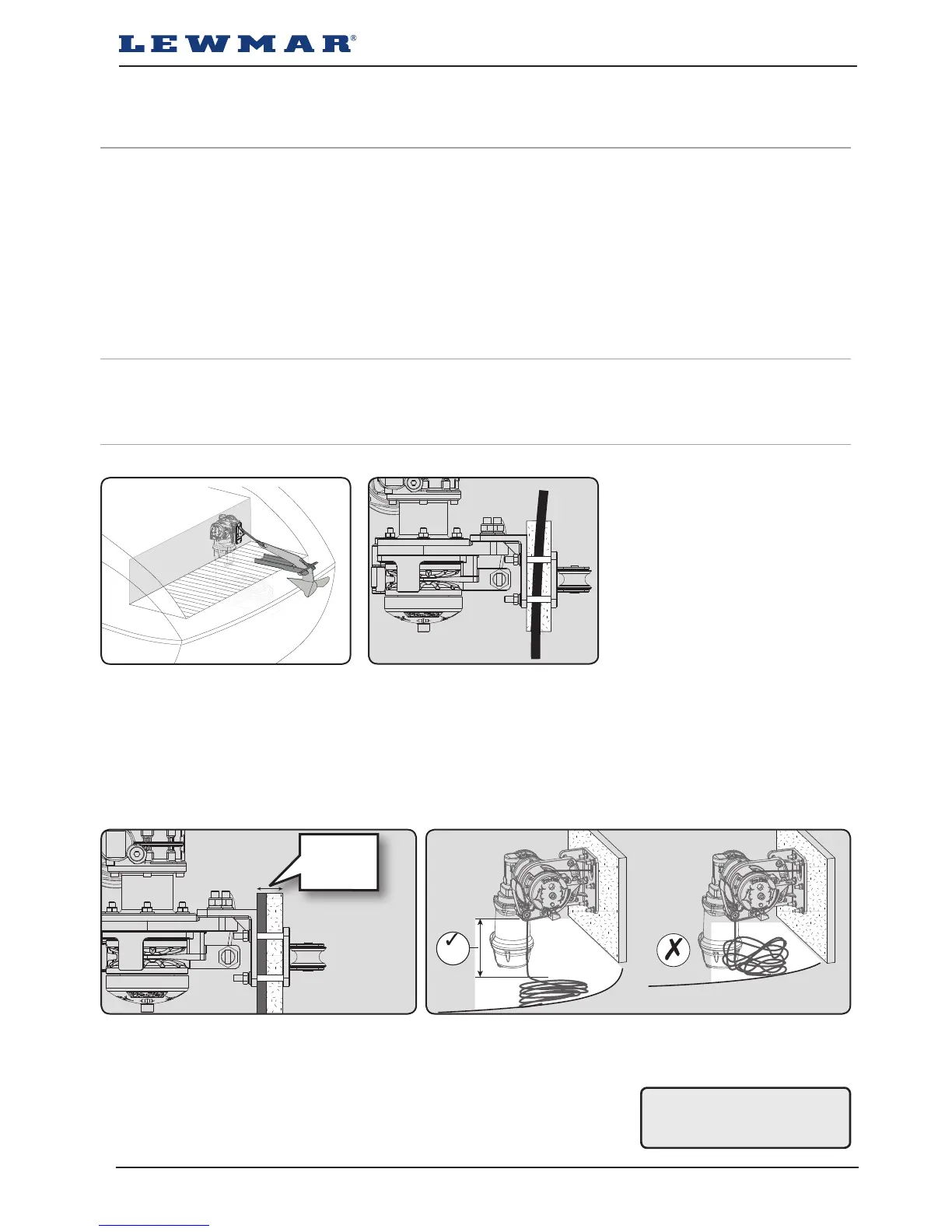

1. Select an appropriate position taking into consideration the position of the anchor roller and the locker behind

the bulkhead . Lead from the roller should be fed in-line back to the the pulley and along its centre line.

2. If the bulkhead is not flat, a suitable mounting pad may be required to take up camber or sheer.

NOTE: If in doubt about the suitable construction of the pad consult a qualified marine engineer.

The bulkhead is an integral component of the windlass. It has to secure the windlass and be strong enough

to cope with the high torque stresses involved in recovering the anchor. Thin bulkhead made of foam or balsa

laminate construction, will require reinforcement in order to spread the loads applied while the windlass is in

use.

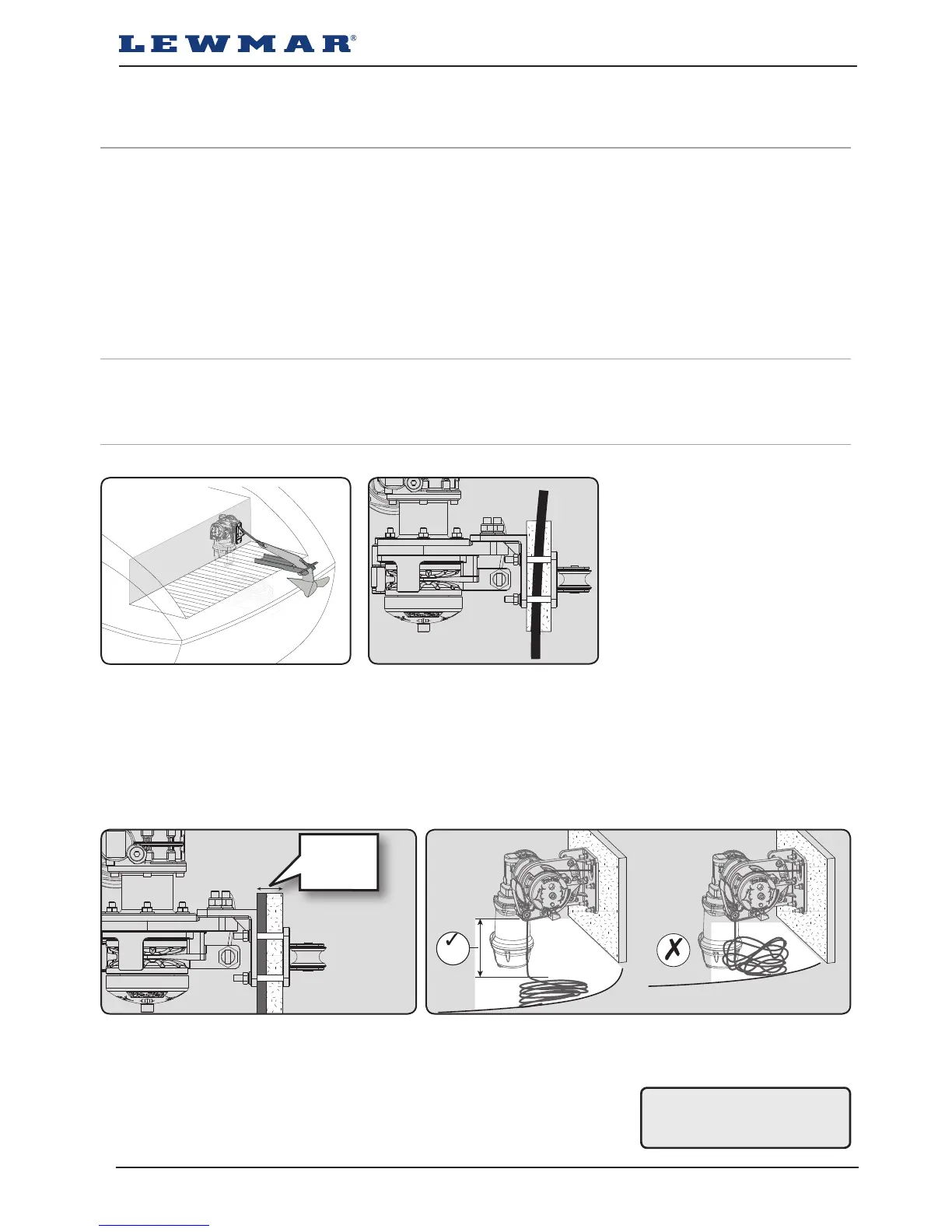

1. Lewmar recommends a minimum bulkhead thickness of 25mm (1”),

M8 Screws supplied suit bulkhead and packing thickness of 25-30mm (1” - 1 ³/₁₆” ).

Note: For thicker bulkheads, please source suitable length M8 countersunk screws.

2. Check clearance behind the bulkhead to fit the windlass including the motor

gearbox and allow for sufficient vertical fall (minimum of 300 mm /12” at all

times) for the lead line when hauling in.

WINDLASS INSTALLATION

• An appropriate marine sealant

• Electric drill and 9mm (⅜”) drill bit

• 50mm (2”) Hole Saw

• 5mm (³/₁₆”) Allen Key

• 13mm (½”) Spanner

WIRING INSTALLATION

• Crimping Pliers / Wire Stripper

• Suitable electrical cable and crimp terminals

4.1 Basic requirements

Each installation requires the following tools:

WARNING! Failure to

provide minimum vertical

fall will cause jamming.

Loading...

Loading...