3 4

1 2

6

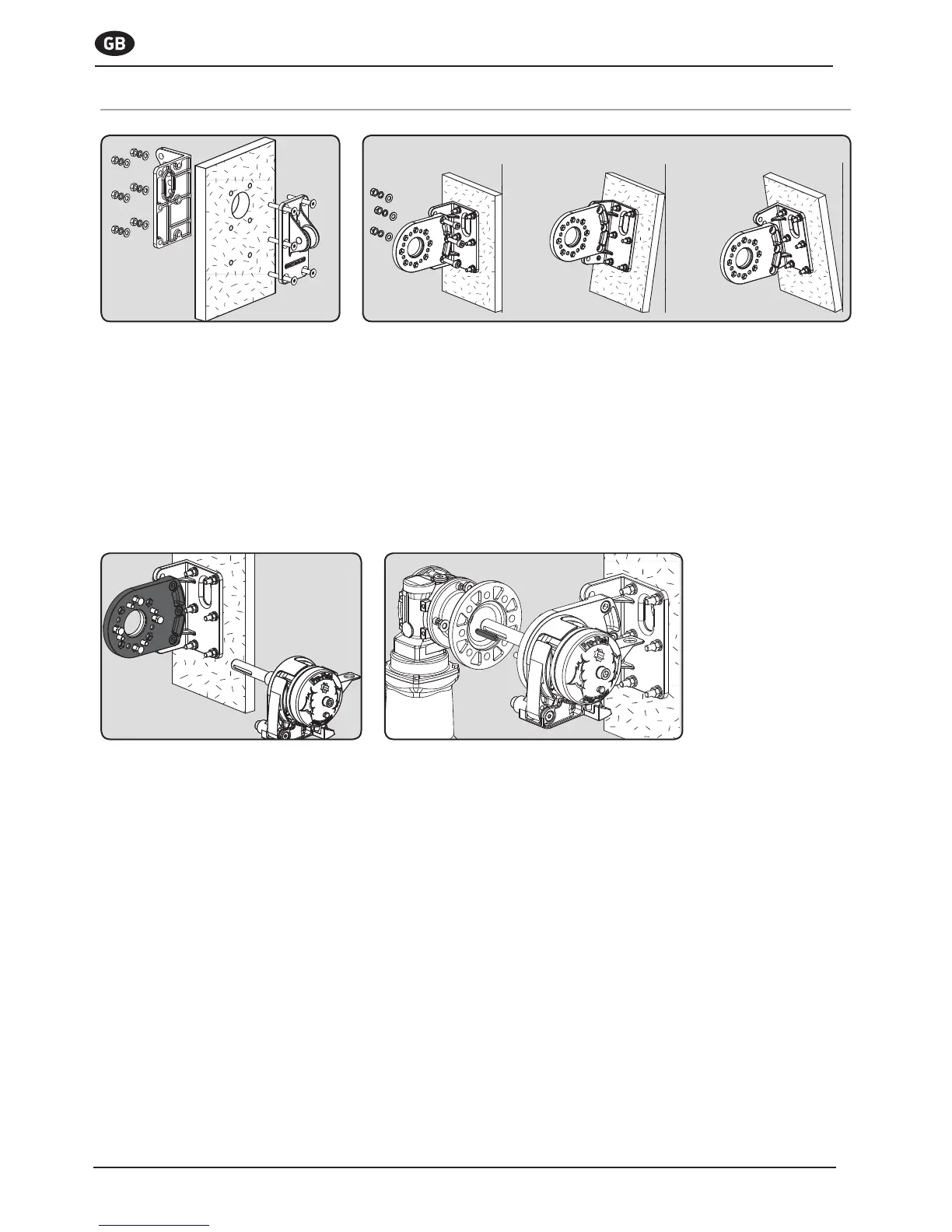

1. Using the template and aer you have checked all the bulkhead requirements cut the following holes:

• Using a 9mm (⅜”) diameter drill bit, make the six holes to fit M8 mounting screws.

• With a 50mm (2”) diameter hole saw, make one hole for the rode to pass through.

• To help avoid water absorption by the deck, apply an appropriate marine sealant to the freshly cut hole edges.

• Assemble and tighten screws to 21Nm using a 5mm Allen key and 13mm spanner

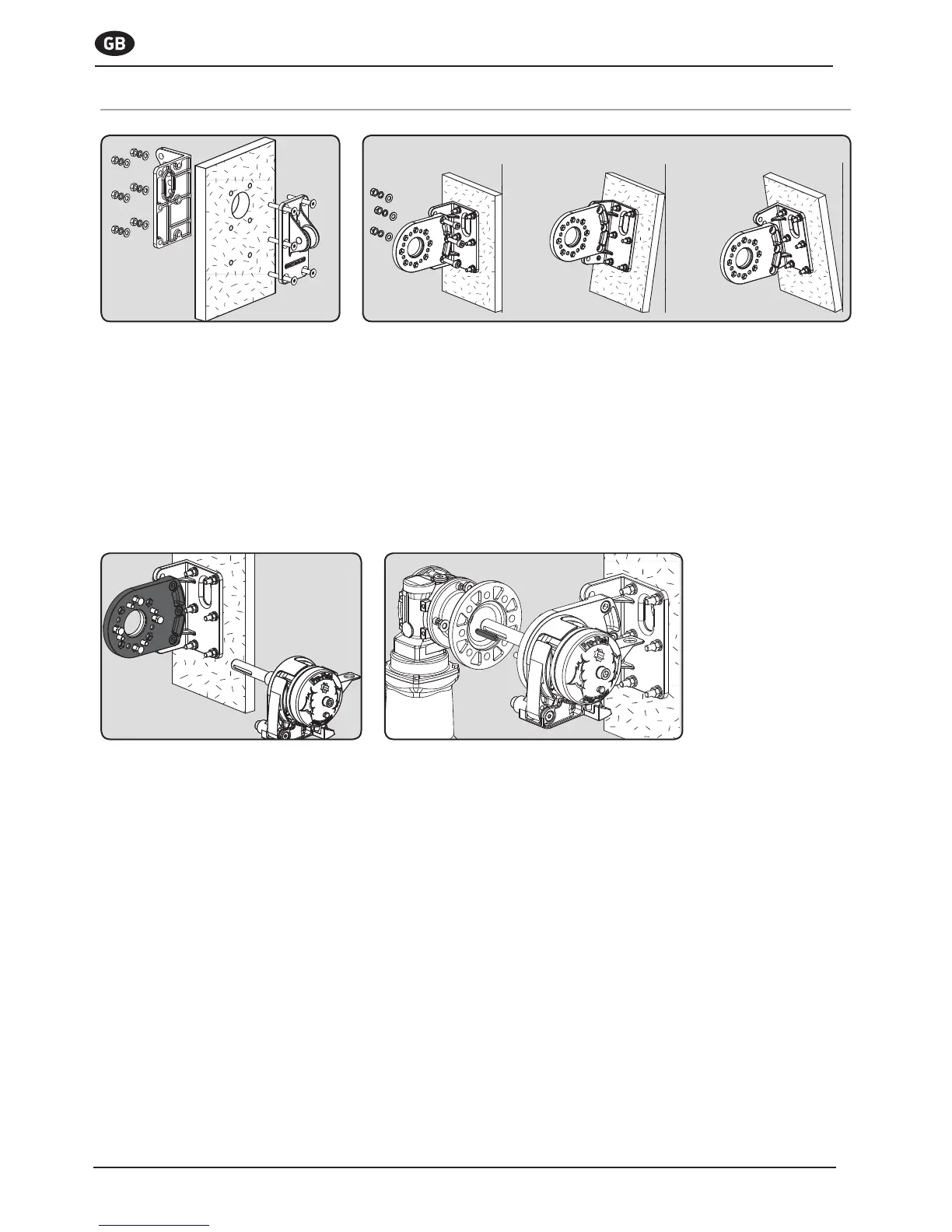

2. The mounting bracket allows 3 different positions.

Select the desired position depending on the angle of the bulkhead.

• Secure the mounting plate in the chosen position using M10 screws and tighten to 43Nm using an 8mm allen

key and 17mm spanner.

4.4 Bulkhead fitting

3. Position 4 off gearbox mounting bolts, registering hex heads in recesses of housing, to give desired motor /

gearbox position.

• Insert 4 off M8 screws into prefered position and secure main unit. Tighten to 21Nm using a 6mm Allen key

4. Insert key into drivesha and slide motor / gearbox onto sha and secure to main unit using 4 off M8 nuts and

washers. Torque to 21Nm using a 13mm spanner.

Loading...

Loading...