2. Faults

2-1. Power

2-2. Compressor

TROUBLE DIAGNOSIS

-67-

Problems Causes Checks Measures Remarks

No power on - Power cord cut. - Check the voltage with tester. -Replace the components.

outlet. - Faulty connector insertion. - Check visually. -Reconnect the connecting parts.

- Faulty connection between plug - Check visually. -Reconnect the connecting parts.

and adapter.

Fuse blows out. - Short circuit by wrong connection. - Check the fuse with tester - Find and remove the cause of - Replace with rated

- Low voltage products are or visually. problem (ex. short, high voltage, fuse after confirming

connected to high voltage. - Check the input volt are with tester low voltage). its specification.

- Short caused by vermin. (between power cord and products). - Replace with rated fuse.

- Electricity leakage. - Check the resistance of power cord ■ If fuse blowns out

- High voltage. with tester (if it is 0Ω, it is shorted). frequently, confirm

- Short circuit of components the cause and repair.

(tracking due to moisture and dust

penetration).

Problems Causes Checks Measures Remarks

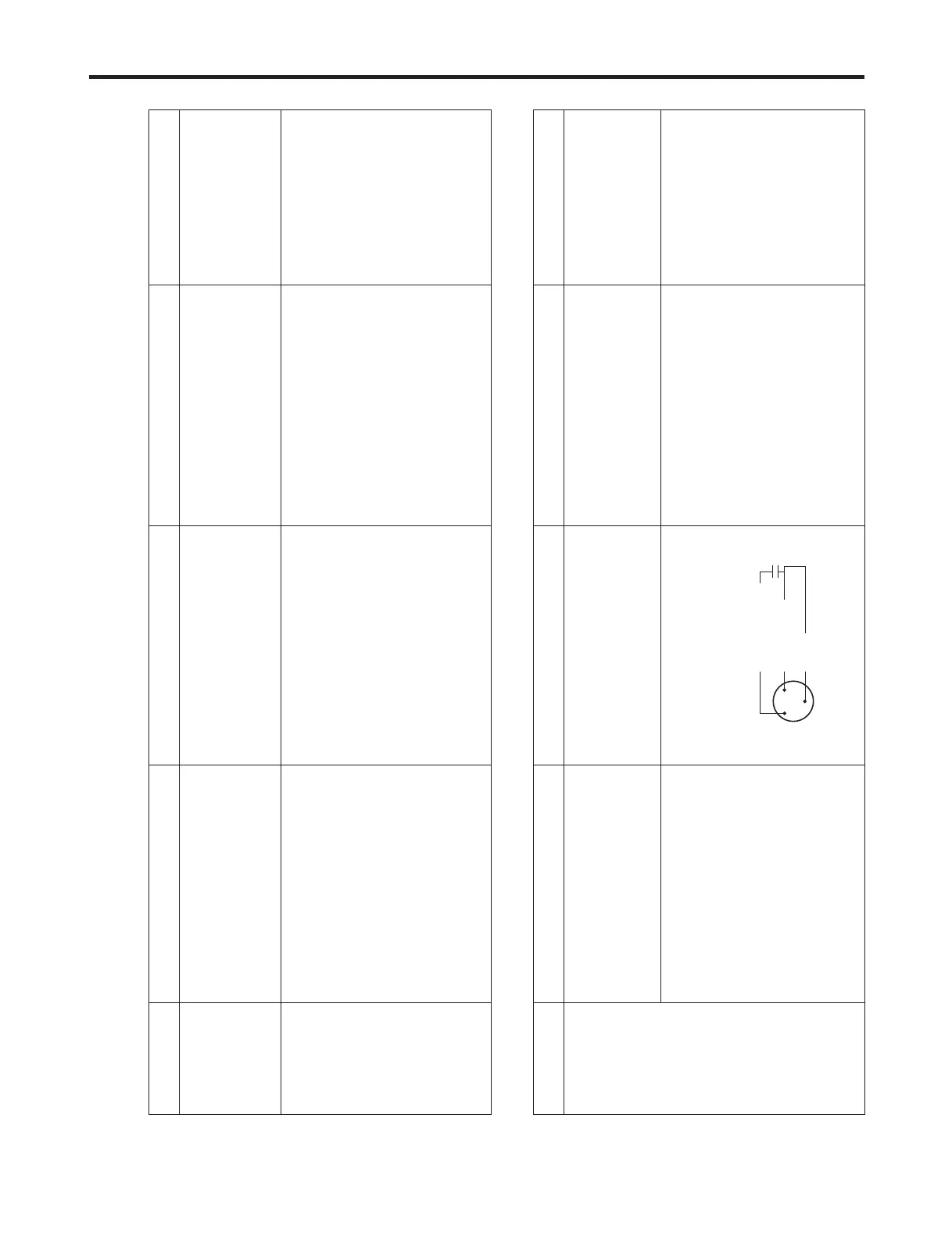

Compressor - Faulty PTC. - Check the resistance. - If resistance is infinite, replace it

does not Vlaue:∞ is defective. with new one.

operate. - If it is not infinite, it is normal.

- Check other parts.

- Compressor is locked up. - If compressor assembly parts are - During forced operation:

normal (capacitor, PTC, OLP), - Operates: Check other parts.

apply power directly to the - Does not operate operate:

compressor to force operation. Replace the frozen compressor

with new one, weld, evacuate,

and recharge refrigerant.

OLP It starts as soon as it is • Refer to weld repair procedures.

contacted.

Auxiliary winding

Main winding

Power

Loading...

Loading...