Removal Area for Liquid/Gas pipe

bottom side connections.

CAUTION

• Do not give damage to the pipe/base during the Knock Out

work.

• Proceed to pipe work after removing burr after Knock Out work.

• Perform sleeve work to prevent damage to the wire when con-

necting wires using knock Outs.

!

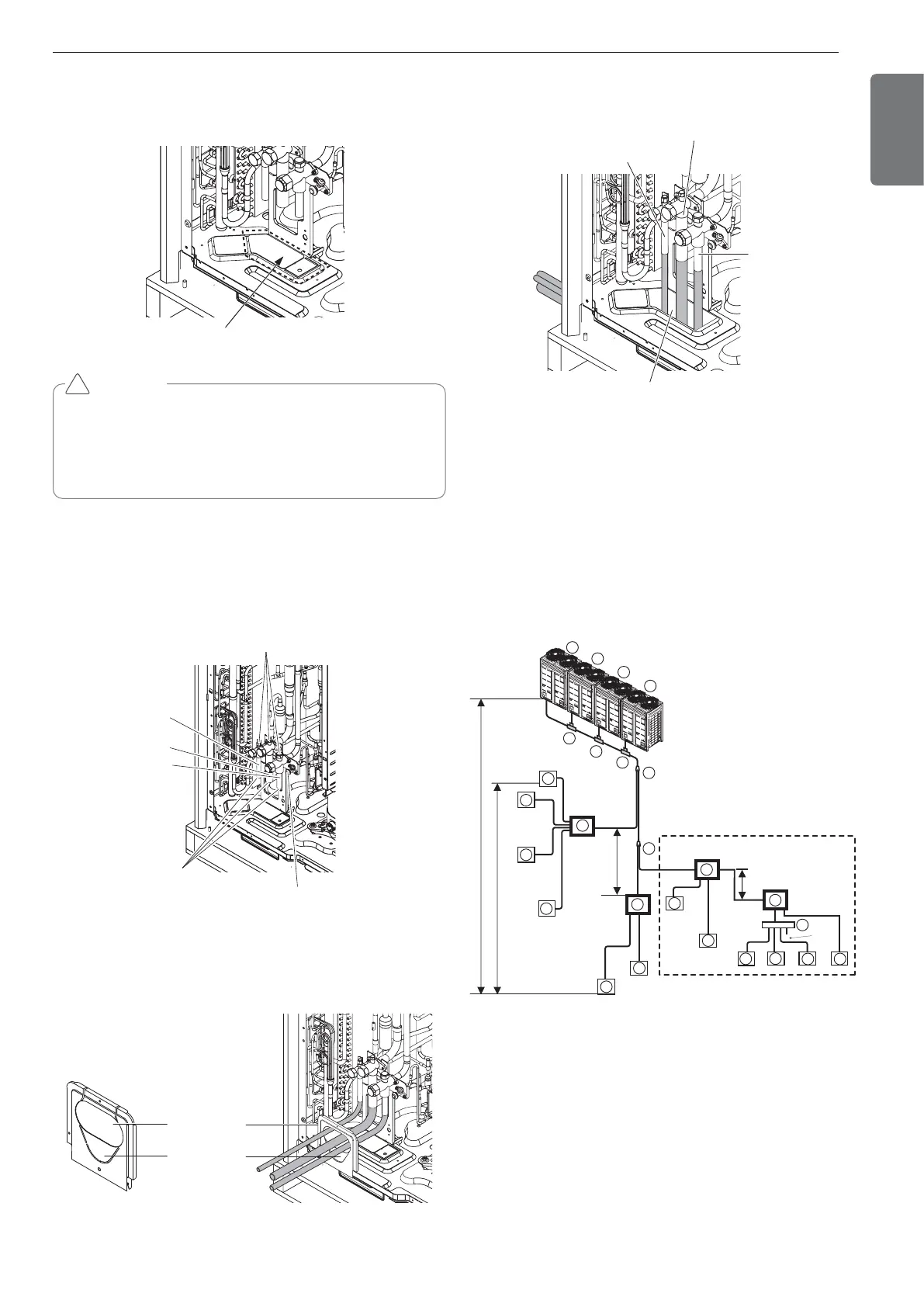

Remove leakage prevention cap

• Remove the leakage prevention cap attached to the outdoor unit

service valve before pipe work.

• Proceed the leakage prevention cap removal as follows:

- Verify whether the liquid/gas pipes are locked.

- Extract remaining refrigerant or air inside using the service port.

- Remove the leakage prevention cap

Leakage Prevention Cap

Low Pressure Gas pipe

Service Port

Refrigerant Charging Port

Liquid pipe

High Pressure Gas pipe

Pipe Drawing Out during Single / Series connection

Method of drawing out pipes on the front side

- Proceed with the pipe work as shown in the below figure for front

side pipe drawing out.

Pipe Knock Out

for High Pressure

Gas pipe

Pipe Knock Out for

Liquid/Gas pipes

Method of drawing out pipes on the bottom side

- Drawing out common pipe through side panel

Liquid pipe

Low Pressure Gas pipe

High Pressure

Gas pipe

Remove pipe knock out

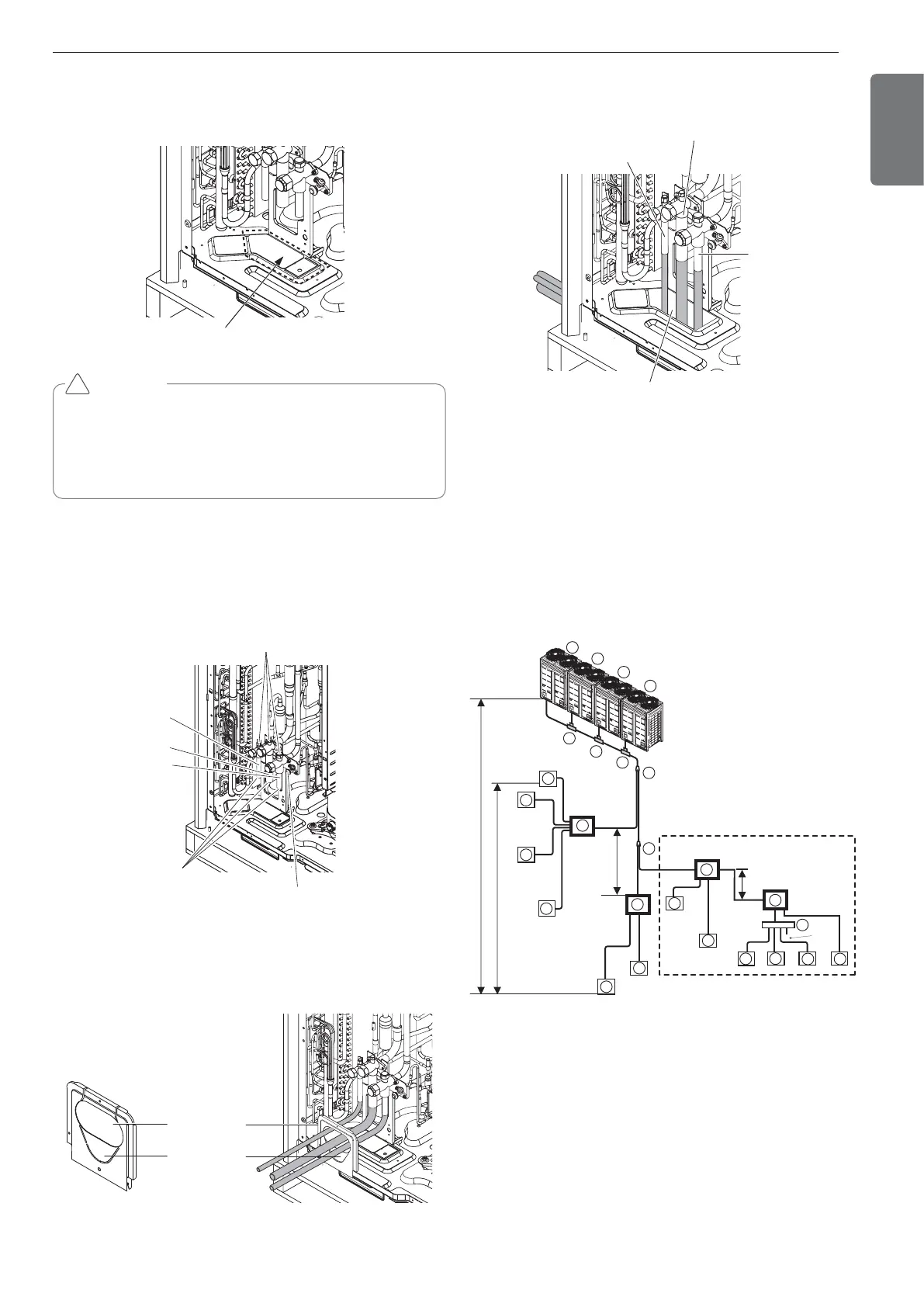

Refrigerant piping system

3 Outdoor Units

Example : 12 Indoor Units connected

Ⓐ : Outdoor Unit

Ⓑ : Y branch

Ⓒ : Indoor Unit

Ⓓ : Connection branch pipe between Outdoor units : ARCNB21

Ⓔ : Connection branch pipe between Outdoor units : ARCNB31

Ⓕ : Connection branch pipe between Outdoor units : ARCNB41

Ⓖ : Header

Ⓗ : HR Unit

- Case 1 ("a") : Maximum height is 15m if you install with Y branch.

- Case 2 ("b") : Maximum height is 5m in serial connection of HR units.

A2

H1

C

1

2

C

C

C

3

4

E

F

D

A

F3

C1

B

C2

C3

*

B1

B2

A3

A4

a

b

c

d

e

g

j

k

x

l

m

n

sealing

f

i

H

h

"a"

"b"

F2

F1

H2

H4

G

H3

Slave 1

Slave 2

Slave 3

ODU Capacity

Master ≥ Slave1 ≥ Slave 2

C

5

C

6

C

7

C

8

C

10

C

9

C

11

C

12

A1

Master

Conditional

To satisfy below condition to make 40 m ~ 90 m of pipe length after first branch.

1) Diameter of pipes between first branch and the last branch should be in-

creased by one step, except pipe diameter B,C3 is same as Diameter A

Ø6.35 ’ Ø 9.52 ’ Ø 12.7 ’ Ø 15.88 ’ Ø 19.05 ’ Ø 22.2 ’ Ø 25.4*, Ø 28.58 ’

Ø 31.8*, Ø 34.9 ’ Ø 38.1*

* : It is not necessary to size up.

2) While calculating whole refrigerant pipe length, pipe B,C3 length should

be calculated twice.

A + B x 2 + C3 x 2 + C1 + C2 + a + b + c + d + e + f + g + i + j + k + l + m + n ≤ 1,000 m

3) Length of pipe from each indoor unit to the HR Unit

(a,b,c,d,e,f,g,i,j,k,l,m,n) ≤ 40 m

4)

[Length of pipe from outdoor unit to the farthest indoor unit D12 (A+B+C+D+e)]

-

[Length of pipe outdoor unit to the closest indoor unit D1(C1+a)] ≤ 40 m

Preparation Work

- Use Knock Outs of Base Pan of the outdoor unit for Left/Right or

Bottom pipe drawing outs.

Loading...

Loading...