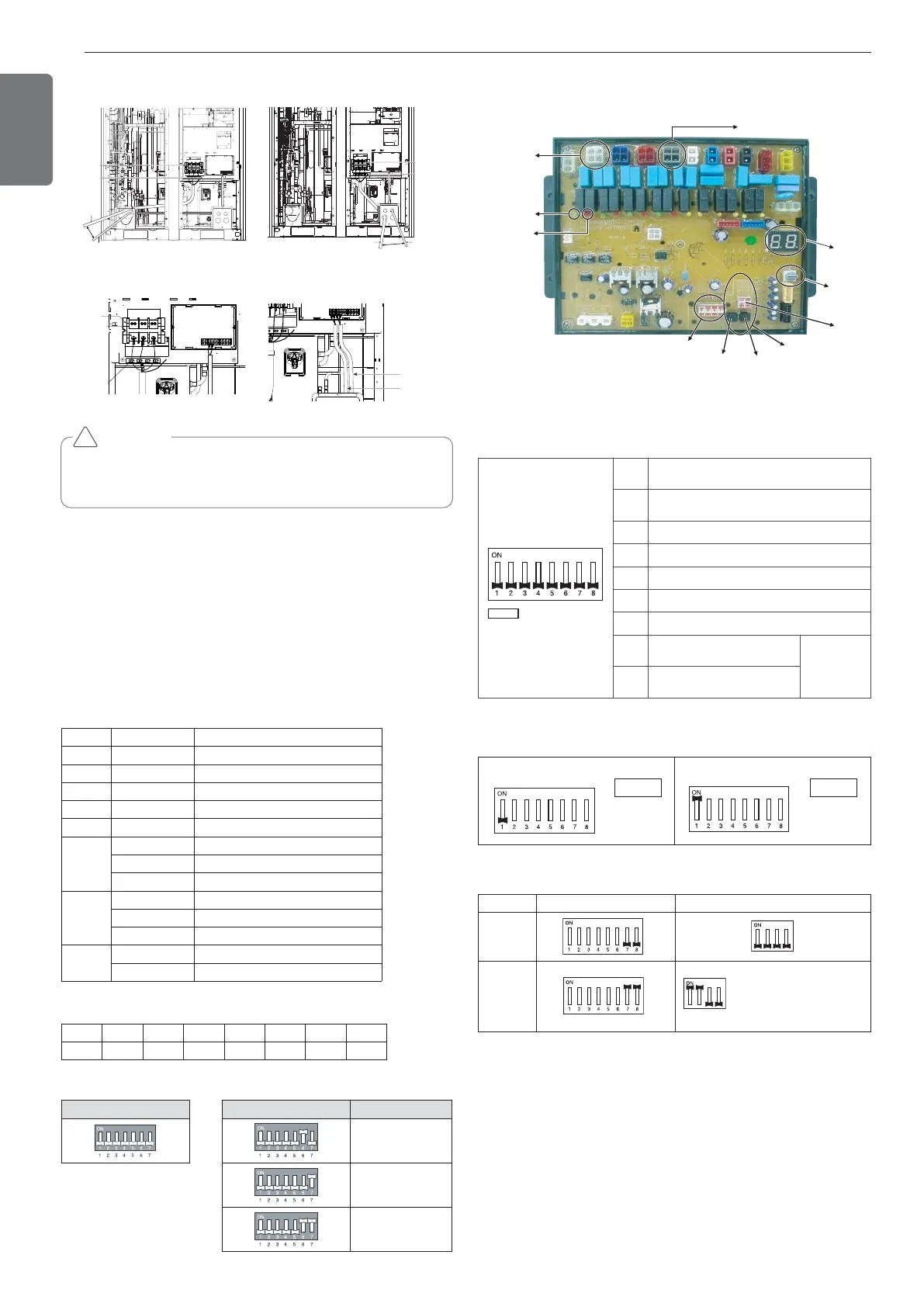

Switch for setup of HR Unit

Main function of SW02M

1. Selection of the method for addressing valves of an HR unit

(Auto/Manual)

2. Setting the zoning control

ON

S/W

Selection

No.1

Method for addressing valves of an HR

unit (Auto/Manual)

No.2 Model of HR unit

No.3 Model of HR unit

No.4 Model of HR unit

No.5 Valve group setting

No.6 Valve group setting

No.7

Use only in factory pro-

duction (preset to “OFF”)

Zoning set-

ting (“ON”)

No.8

Use only in factory pro-

duction (preset to “OFF”)

Turn the dip switch of

the zoning branch on.

Ex) Branch 1,2 are zon-

ing control.

HR Unit PCB

28

ENGLISH

CAUTION

It should be wiring power cables or communication cables to avoid

interference with the oil level sensor. Otherwise, That oil level sensor

would be operated abnormally.

!

Front Side 1 Front Side 2

Main Power Connection Communication Connection

Checking the setting of outdoor units

Checking according to dip switch setting

- You can check the setting values of the Master outdoor unit from the

7 segment LED.

The dip switch setting should be changed when the power is OFF.

Checking the initial display

The number is sequentially appeared at the 7 segment in 5 seconds

after applying the power. This number represents the setting condition.

• Initial display order

• Example) ARUB620DTE4

• Master Unit • Slave Unit

Dip switch setting Dip switch setting ODU Setting

Slave 1

Slave 2

Slave 3

Order No Mean

①

8~20 Master model capacity

②

10~20 Slave 1 model capacity

③

10~20 Slave 2 model capacity

④

10~20 Slave 3 model capacity

⑤

8~80 Total capacity

⑥

1 Cooling Only

2 Heat Pump

3 Heat Recovery

⑦

38 380V model

46 460V model

22 220V model

⑧

1 Full function

2 Core function

① ② ③ ④ ⑤ ⑥ ⑦ ⑧

18 16 14 14 62 3 46 1

Loading...

Loading...