13

ENGLISH

HR unit HR unit

sealing

Changeover under control Auto changeover Changeover under control

Zoning control group 1 Zoning control group 2

(Max. 8 Indoor Units)

(Max. 8 Indoor Units)

Installation of Zoning Control

Some indoor unit can be connected to one port of HR unit.

WARNING

!

• A branch pipe of HR unit allows up to 14.5 kW (48 kBtu/h) based

on cooling capacity of the indoor unit. (up to 14.5 kW (48 kBtu/h)

for max installation)

• The maximum total capacity of indoor units connected to a

PRHR043A HR unit is 58 kW (192 kBtu/h).

• The maximum number of indoor units connected to a PRHR043A

HR unit are 32 indoor units. (The Maximum indoor units per a

branch pipe of HR unit are 8 indoor units)

• There is not operate “Auto-changeover” & “Mode override”

function in the zoning group.

• When there are operating indoor units on cooling(heating) mode,

another indoor units aren’t changed on heating(cooling) mode in

the zoning group.

[Reducers for indoor unit and HR unit]

[Unit : mm(inch)]

Models

High pressure

-

Gas pipe

Low pressure

Liquid pipe

Indoor unit

reducer

HR unit

reducer

PRHR023(A)

OD 22.2(7/8) Ø 19.05(3/4) Ø 15.88(5/8)

OD 15.88(5/8) Ø 12.7(1/2)

Ø 6.35(1/4)OD 9.52(3/8)

Ø 6.35(1/4)OD 9.52(3/8)

OD 19.05(3/4) Ø 15.88(5/8)

OD 12.7(1/2) Ø 9.52(3/8)

Ø

12.7(1/2)

OD 22.2(7/8) Ø 19.05(3/4) Ø 15.88(5/8)

OD 15.88(5/8) Ø 12.7(1/2)

PRHR033(A)

PRHR043(A)

PRHR063(A)

PRHR083(A)

OD 19.05(3/4) Ø 15.88(5/8)

OD 28.58(1-1/8) Ø 22.2(7/8) Ø 19.05(3/4)

OD 15.88(5/8) Ø 12.7(1/2) Ø 9.52(3/8)

OD 12.7(1/2) Ø 9.52(3/8)

OD 15.88(5/8) Ø 12.7(1/2)

CAUTION

1 Use the following materials for refrigerant piping.

• Material: Seamless phosphorous deoxidized copper pipe

• Wall thickness : Comply with the relevant local and national

regulations for the designed pressure 3.8 MPa

(551.14 psi). We recommend the following table

as the minimum wall thickness.

Outer diameter

[mm(inch)]

6.35

(1/4)

9.52

(3/8)

12.7

(1/2)

15.88

(5/8)

19.05

(3/4)

22.2

(7/8)

25.4

(1)

28.58

(1-1/8)

31.8

(1-1/4)

34.9

(1-3/8)

38.1

(1-1/2)

41.3

(1-5/8)

44.45

(1-3/4)

53.98

(2-1/8)

Minimum thickness

[mm(inch)]

0.8

(1/32)

0.8

(1/32)

0.8

(1/32)

0.99

(5/128)

0.99

(5/128)

0.99

(5/128)

0.99

(5/128)

0.99

(5/128)

1.1

(3/64)

1.21

(3/64)

1.35

(7/128)

1.43

(7/128)

1.55

(1/16)

2.1

(11/128)

2 Commercially available piping often contains dust and other

materials. Always blow it clean with a dry inert gas.

3 Use care to prevent dust, water or other contaminants from

entering the piping during installation.

4 Reduce the number of bending portions as much as possible, and

make bending radius as big as possible.

5 Always use the branch piping set shown below, which are sold

separately.

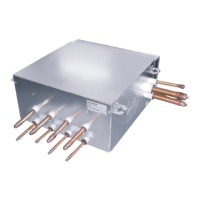

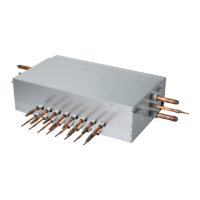

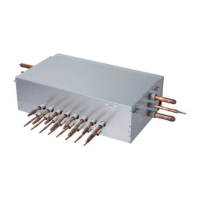

Y branch

Header

4 branch 7 branch 10 branch

ARBLB01621, ARBLB03321,

ARBLB07121, ARBLB14521,

ARBLB23220

ARBL054 ARBL057 ARBL1010

ARBL104 ARBL107 ARBL2010

6 If the diameters of the branch piping of the designated refrigerant

piping differs, use a pipe cutter to cut the connecting section and

then use an adapter for connecting different diameters to connect

the piping.

7 Always observe the restrictions on the refrigerant piping (such as

rated length, difference in height, and piping diameter).

Failure to do so can result in equipment failure or a decline in

heating/cooling performance.

8 A second branch cannot be made after a header. (These are shown

by .)

9 The Multi V water will stop due to an abnormality like excessive or

insufficient refrigerant. At such a time, always properly charge the

unit. When servicing, always check the notes concerning both the

piping length and the amount of additional refrigerant.

10 Never perform a pump down. This will not only damage the

compressor but also deteriorate the performance.

11 Never use refrigerant to perform an air purge. Always evacuate

using a vacuum pump.

12 Always insulate the piping properly. Insufficient insulation will

result in a decline in heating/cooling performance, drip of

condensate and other such problems.

13 When connecting the refrigerant piping, make sure the service

valves of the Outdoor Unit is completely closed (the factory

setting) and do not operate it until the refrigerant piping for the

Outside and Indoor Units has been connected, a refrigerant

leakage test has been performed and the evacuation process has

been completed.

14 Always use a non-oxidizing brazing material for brazing the parts

and do not use flux. If not, oxidized film can cause clogging or

damage to the compressor unit and flux can harm the copper

piping or refrigerant oil.

Ⓐ To Outdoor Unit

Ⓑ Sealed Piping

A

A

B

Loading...

Loading...