17

ENGLISH

1 inch or

3/4 inch

socket

Cover

Micro-switch

Adjustment screw

Vibration plate

Bellows

Pad

Installation of flow switch

• The flow switch must be installed at the horizontal pipe of the heat

water supply outlet of the product and check the direction of the heat

water flow before the installation. (Picture 1)

• When connecting the flow switch to the product, remove the jump

wire to connect to the communication terminal (5(A) and 5(B)) of the

outdoor unit control box. (Picture 2, 3) (Open the cover of the flow

switch and check the wiring diagram before connecting the wires.

The wiring method can differ by the manufacturer of the flow

switch.)

• If necessary, adjust the flow rate detection screw after consulting

with an expert and adjust to the minimum flow rate range. (Picture 4)

(Adjust the flow switch to touch the contact point when the flow rate

reaches minimum flow rate.)

- Minimum flow rate : 6 TON-17.8 GPM, 8 TON-17.8 GPM, 10 TON-

17.8 GPM, 12 TON-17.8 GPM, 16 TON-25.4 GPM

Picture 1 Picture 2

Picture 3

Picture 4

CAUTION

!

• If the set value does not satisfy the minimum flow rate or if the

set value is changed by the user arbitrarily, it can result in

product performance deterioration or serious product problem.

• If the product is operated with the heat water supply not

flowing smoothly, it can damage the heat exchanger or cause

serious product problems.

• In case of CH24 or CH180 error, there is a possibility that the

plate type heat exchanger is partially frozen inside. In this case

resolve the issue of partial freezing and then operate the

product again. (Cause of partial freezing : Insufficient heat water

flux, water not supplied, insufficient coolant, alien particle

penetrated inside plate type heat exchanger)

• When the product operates while the flow switch touches the

contact point at the flow rate range out of the permitted range,

it can cause product performance deterioration or serious

product problem.

• Must use the normal closed type flow switch

- Circuit of outdoor unit is normal closed type.

Flow switch work

• You must install the flow switch to the water collection pipe system

connecting to the outdoor unit.

(Flow switch acts as the 1st protection device when the heat water

is not supplied. If a certain level of water does not flow after

installing the flow switch, an error sign of CH 189 error will be

displayed on the product and the product will stop operating.)

• When setting the flow switch, it is recommended to use the product

with default set value to satisfy the minimum flow rate of this

product. (The minimum flow rate : 6 TON-17.8 GPM, 8 TON-17.8

GPM, 10 TON-17.8 GPM, 12 TON-17.8 GPM, 16 TON-25.4 GPM)

• Select the flow switch with the permitted pressure specification

considering the pressure specification of the heat water supply

system. (Control signal from outdoor unit is AC 220 V.)

PIPE CONNECTIONS BETWEEN

INDOOR AND OUTDOOR UNIT

- Pipe connections can be done on the front side or on the side

according to the installation environments.

- Be sure to let 0.2 kgf/cm

2

(2.8 psi) Nitrogen flow in the pipe when

welding.

- If Nitrogen was not flown during welding, many oxidized membranes

may form inside the pipe and disturb the normal operations of valves

and condensers.

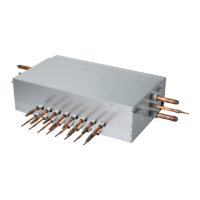

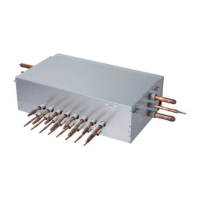

Refrigerant piping system

3 Outdoor Units

Example : 12 Indoor Units connected

Ⓐ : Outdoor Unit

Ⓑ : Y branch

Ⓓ : Indoor Unit

Ⓔ : Connection branch pipe between Outdoor units : ARCNB31

Ⓕ : Connection branch pipe between Outdoor units : ARCNB21

Ⓗ : Header

Ⓘ : HR Unit

- Case 1 ("a") : Maximum height is 15 m(49.2 ft) if you install with Y

branch.

- Case 2 ("b") : Maximum height is 5 m(16 ft) in serial connection of HR

units.

A1

I1

D

1

0

m

or l

e

s

s

1

2

D

D

D

3

4

A

C1

B

C2

C3

*

B1

B2

A2

A3

a

b

c

d

e

g

j

k

D

x

l

m

n

sealing

f

i

H

h

"a"

"b"

E

F

I2

I4

H

I3

Master

Slave 1

Slave 2

ODU Capacity

Master ≥ Slave1 ≥ Slave 2

D

5

D

6

D

7

D

8

D

10

D

9

D

11

D

12

ʺ

ʻ

Refrigerant Pipe

Regulator

Nitrogen

Taping

Valve

Nitrogen

Direction

Nitrogen

Direction

For Heat Recovery System Installation

WARNING

!

• Piping length from outdoor unit branch to outdoor unit ≤ 10 m

(32.8 ft), equivalent length : max 13 m (42.7 ft) (for 12 Ton (144

kBtu) or more)

* If the large capacity indoor units (Over 48 kBtu; using over

Ø 15.88 (5/8) / Ø 9.52 (3/8)) are installed, it should be used the

Valve Group setting.

Loading...

Loading...