Do you have a question about the LG Multi V PRHR042A and is the answer not in the manual?

Hazards and instructions for safe installation by authorized personnel.

Warnings and precautions for safe product operation.

Precautions for installation environment, noise, and refrigerant leaks.

Precautions for operation in special environments and handling.

Minimum space requirements for unit installation.

Instructions for securely fixing the unit with bolts and base support.

Warnings regarding support strength, wind/earthquake resistance, and ground support.

Procedure for correct flaring work to prevent gas leakage.

Dimensions and torque specifications for flare connections.

Guidelines for connecting flare nuts and performing leak checks.

Principles for drying, cleanliness, and airtightness in refrigerant piping.

Specific piping installation for HR systems.

Guidelines for connecting pipes and operating valves.

Warnings about refrigerant handling during welding.

Instructions for connecting multiple outdoor units.

Warning before brazing work.

Limitations and warnings for HR unit branch pipe and capacity.

Recommended materials and wall thickness for refrigerant piping.

Importance of following piping restrictions to prevent failure.

Specific precautions for heat pump system pipe connection.

Warnings related to refrigerant handling during welding.

Importance of nitrogen flow during welding.

Warnings about refrigerant handling and pipe diameter selection.

Using knock-outs for pipe drawing outs and wiring.

Overview of refrigerant piping for 3 outdoor units.

Methods for drawing out pipes on front and bottom sides.

Specifications for pipe diameters from branches.

Warnings regarding HR unit serial connections and pipe length differences.

Overview of refrigerant piping for 1 outdoor unit.

Methods for drawing out pipes on front and bottom sides.

Procedure for drawing out common pipes through side panels.

Connection patterns for Y branch method.

Connection patterns for Y branch method.

Table showing limit pipe lengths for series units.

Warnings about pipe diameter and length calculations.

Pipe diameter specifications based on ODU capacity and conditions.

Pipe diameter specifications based on downward indoor unit capacity.

Warnings about pipe diameter B being larger than A.

Pipe diameter selection for indoor unit connections.

Calculation method for additional refrigerant charge.

Regulation for refrigerant leakage and concentration limits.

Warnings during refrigerant charging.

Instructions for fitting branch pipes.

Pipe configurations for Y branch pipes.

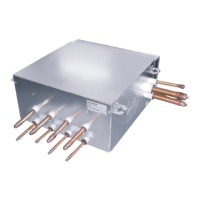

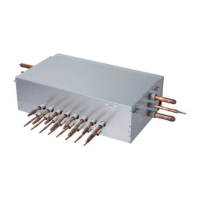

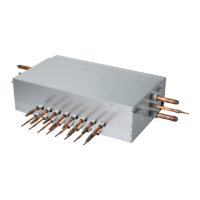

Pipe configurations for various header models.

Setting procedure for vacuum mode using DIP switches.

Procedure for performing a nitrogen gas leak test.

Procedure for vacuum drying the system.

Warnings about using vacuum pumps and flammable gases.

Warnings about refrigerant handling and recharge.

Warnings about using authorized electricians and power supply capacity.

Guidelines for laying power wiring and connecting terminals.

Specifications for communication and power cables.

Warning about outdoor air temperature sensor exposure.

Recommended spacing between communication and power cables.

Warnings regarding power supply, cable size, and wiring regulations.

Example wiring for communication cables.

Warnings about ground lines, separate switches, and reversed phase.

Example wiring for communication cables at different voltages.

Warnings about ground lines, separate switches, and reversed phase.

Warnings about ground lines, separate switches, and reversed phase.

Procedure for connecting main power lines.

Procedure for connecting communication and ground wires.

Checking outdoor unit settings using DIP switches and 7-segment display.

Selecting automatic or manual addressing for HR unit valves.

Setting zoning control for HR unit branches.

Warnings about using HR unit models with fewer pipes than available.

Instructions for using the rotary switch for HR unit addressing.

Manual valve addressing procedure using DIP and tact switches.

Setting manual valve addresses for non-zoning configurations.

Setting manual valve addresses for zoning configurations.

Setting the Valve Group Control using SW01D.

Manual pipe detection procedure using DIP and push switches.

Manual addressing steps for valves #1 and #6.

Procedure for automatic addressing of indoor units.

Manual pipe detection for zoning settings.

Manual pipe detection for zoning with multiple indoor units.

| Brand | LG |

|---|---|

| Model | Multi V PRHR042A |

| Category | Air Conditioner |

| Language | English |

Loading...

Loading...