51

ENGLISH

Water supply system test run

Before executing the test run for the product, you must first test the

heat source water system.

The test run for the product must be executed after checking the flow

rate and temperature of the heat source water supplied.

Equipment design

Execute the

product test run

Water pipe system

installation

Water supply pipe

and product connection

Water supply

system test run

Judging whether there

is any problem with

the water supply

Design the system including cooling tower, boiler, pump etc.

- Check the equipment capacity (Water volume, temperature

control range).

Connect the water pipe to the inlet/outlet of the product so

that the water can be supplied to the product.

Execute water supply system test run

- The product does not operate but the pump and water

supply equipment will operate to flow the Heat source

water to the heat exchanger on the product side.

- Flow the water to all water piping system to clean any alien

particles inside the pipes and execute an air purge to

remove an air within the pipes to make the water supply

smoother.

- Clean all the strainers of water pipe including around

outdoor units.

Execute the test of water supply system without operating

the product.

- Check whether outdoor unit inlet/outlet flow rate complies

to the product specification. Standard Water volume is

96 LPM based on 10 HP and 196 LPM based on 20 HP.

- Check the water supply temperature. whether is OK

After checking the normal condition of the water supply,

execute the test run of the product.

To prevent the freezing of the heat exchanger when the

refrigerant is discharged with the water supply blocked,

discharge the refrigerant after draining out around the

outdoor unit.

Install the water pipe

WARNING

!

• Always check whether the water supply is flowing smoothly

before the test run. (If sufficient amount of water is not

flowing, it can burn the product.)

• During the initial test run after installing the product, leaving

the product for more than 3 days or after replacing the

compressor, power must be connected 6 hours prior to the

operation to heat the compressor heater. (If the product is not

heated sufficiently, it can burn the product.)

How to Cope with Abnormal Test Run

Item

Phenomenon

Cause Checkpoint and resolution

Whether

heat

water is

supplied

CH24

Heat water not

supplied or flow

rate is insufficient

Check whether the heat source water

supply pump is operating.

Check whether the heat source water

supply pipe is clogged.

(Clean strainer, valve locked, valve

issue, air trapped etc.)

CH32

Heat water not

supplied or flow

rate is insufficient

Check whether heat source water

supply pump is operating.

Check whether the heat source water

supply pipe is clogged.

(Clean strainer, valve locked, valve

issue, air trapped etc.)

CH34

Heat water not

supplied or flow

rate is insufficient

(During Cooling)

Check whether heat source water

supply pump is operating.

Check whether the heat source water

supply pipe is clogged.

(Clean strainer, valve locked, valve

issue, air trapped etc.)

CH180

Heat water not

supplied or flow

rate is insufficient

(During heating)

Check whether heat source water

supply pump is operating.

Check whether the heat source water

supply pipe is clogged.

(Clean strainer, valve locked, valve

issue, air trapped etc.)

CH189

When connecting

the flow switch,

heat-sourced

water doesn’t

flow or the

amount of its flow

lacks due to the

checked error

related to

heat-sourced

water.

Check whether the heat source water

supply pump is operating.

Check whether the heat source water

supply pipe is clogged.

(Clean strainer, valve locked, valve

issue, air trapped etc.)

Check whether the flow switch is

normal condition.

(Flow switch problem, arbitrary

control, disconnection etc.)

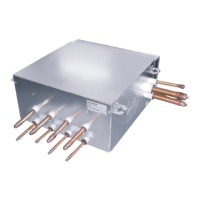

h When CH24 or CH180 error occurs during the test operation of the

heater, the inside of the panel heat exchanger may be partially

frozen and therefore, be sure to get rid of its cause and then,

re-operate the device.

(The root cause of partial freezing: The lack of flow of heat-sourced

water, suspension of water, lack of cooling medium, infiltration of

foreign substance inside of panel heat exchanger)

Loading...

Loading...