14

ENGLISH

WARNING

!

When installing and moving the air conditioner to another site, be

sure to make recharge refrigerant after perfect evacuation.

• If a different refrigerant or air is mixed with the original

refrigerant, the refrigerant cycle may malfunction and the unit

may be damaged.

• After selecting diameter of the refrigerant pipe to suit total

capacity of the indoor unit connected after branching, use an

appropriate branch pipe set according to the pipe diameter of the

indoor unit and the installation pipe drawing.

Cautions in pipe connection/valve operation

Open status when both the pipe and the valve are

in a straight line.

Cut both the pipe and the valve with a cutter to

suit the length

[Don't cut the length of less than 70 mm

(2-3/4”)]

CLOSE OPEN

Elbow

Ball Valve(Gas Pipe)

Ball Valve

(Liquid Pipe)

WARNING

!

Always use extreme care to prevent the refrigerant gas (R410A)

from leakage while using fire or flame. If the refrigerant gas comes

in contact with the flame from any source, such as a gas stove, it

breaks down and generates a poisonous gas which can cause gas

poisoning. Never perform brazing in an unventilated room. Always

conduct an inspection for gas leakage after installation of the

refrigerant piping has been completed.

WARNING

!

After completing work, securely tighten both service ports and

caps so that gas does not leak.

For Heat Pump System Installation

Precautions on Pipe connection / valve operation

Pipe connection is done by connecting from the end of the pipe to the

branching pipes, and the refrigerant pipe coming out of the outdoor

unit is divided at the end to connect to each indoor unit. Flare

connection for the indoor unit, and welding connection for the outdoor

pipe and the branching parts.

① Pipe joint (auxiliary parts): Securely perform brazing with a nitrogen

blow into the service port.(Releasing pressure : 0.02 MPa(2.9 psi) or

less)

② Cap: Remove caps and operate valve, etc. After operation, always

reattach caps (tightening torque of valve cap: 25 N·m (250 kg·cm) or

more). (Don't remove the internal part of the port)

③ Service port: Make the refrigerant pipe vacuum and charge it using

the service port. Always reattach caps after completing work

(tightening torque of service cap: 14 N·m (140 kg·cm) or more).

④ Liquid pipe

⑤ Gas pipe

⑥ Elbow joint (field supply)

h Remove the front panel before pipe

connection

h Must check the pipe (liquid pipe, gas

pipe) before pipe connection

h In case of the heat pump system

installation, be sure to maintain to

close no use pipe like picture.

Liquid pipe

Not used (keep closed)

Not used (keep closed)Not used (keep closed)

Gas pipe

A ≥ B ≥ C

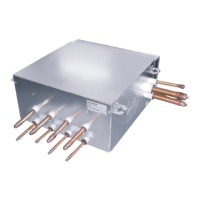

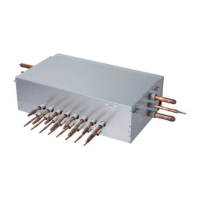

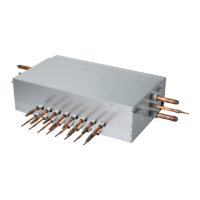

① IDU side connection pipe

② ODU to ODU connection pipe (1st branch)

③ ODU to ODU connection pipe (2nd branch)

(Master)

AB

(Slave1)

C

(Slave2)

2, 3 Outdoor Units

Outdoor Units Model Pipe

2 Unit

Ⓐ

ARCNN21

Liquid Pipe

O.D 15.88(5/8)

I.D 15.88(5/8)

I.D 19.05(3/4)

I.D 22.2(7/8)

O.D 15.88(5/8) I.D 19.05(3/4)

I.D 12.7(1/2) I.D 15.88(5/8)

O.D 12.7(1/2) I.D 9.52(3/8)

I.D 12.7

(1/2)

I.D 9.52

(3/8)

83

(3-9/32)

O.D 19.05(3/4)

70(2-3/4)

I.D 15.88(5/8)

331(13-1/32)

314(12-3/8)

I.D 19.05(3/4)

Gas Pipe

I.D 22.2

(7/8)

I.D 28.58(1-1/8)

I.D 31.8(1-1/4)

I.D 28.58

(1-1/8)

I.D 34.9(1-3/8)

I.D 41.3

(1-5/8)

130(5-1/8)

I.D 38.1

(1-1/2)

I.D 22.2

(7/8)

O.D 28.58

(1-1/8)

I.D 34.9(1-3/8)

111

(4-3/8)

O.D 34.9(1-3/8)

I.D 28.58(1-1/8)

I.D 22.2(7/8)

O.D 28.58

(1-1/8)

416(16-3/8)

408(16-1/16)

I.D 34.9

(1-3/8)

Connection of Outdoor units

When installing ODU series, refer below picture.

[Unit : mm(inch)]

Loading...

Loading...