Service Manual of Rough Terrain Mobile Elevating Work Platform

59

wrench 1/2 16mm, torque wrench

QSP200, AT262 thread locker (on

demand)

Removing the rear axle assembly

△

! CAUTION: Risk of part damage.

The motor maintenance shall only be

performed by the dealers.

△

! CAUTION: Risk of part damage.

The working area and surface where this

step is performed must be clean, and no

impurities will enter the hydraulic system,

which may cause serious component damage.

It is recommended that the dealer perform

maintenance.

△

! CAUTION:

Before refitting, the O-ring of the removed

fitting and/or hose assembly must be replaced

and then tightened to the specified torque

Please refer to hydraulic hose and fitting

torque specifications.

1. Lock the steered wheel.

2. Mark, disconnect and plug the hydraulic hose

of driving motor.

△

! WARNING: Risk of personal injury.

Splashed hydraulic oil may penetrate and

burn the skin. Therefore, please loosen

hydraulic connectors very slowly to reduce the

oil pressure gradually. Do not spray or splash

oil.

3. Remove the fasteners of the driving motor.

4. Pull out the driving motor shaft from the

reducer, and remove the driving motor from

the machine.

△

! CAUTION:

An O-ring is installed between the driving

motor and the reducer. When installing the

driving motor to the machine, make sure that

the O-ring is in the correct position.

5. Lock the steered wheel and place the jack in

the middle of the steering end of the chassis.

6. Unscrew the wheel nuts, but do not remove

them.

7. Raise the machine by 5 cm. Place the bracket

under the chassis for the purpose of

supporting.

8. Unscrew the wheel nuts and remove the tires.

9. Place another jack under the reducer to

support and fix the reducer.

10. Remove the fasteners of the reducer and then

remove the reducer.

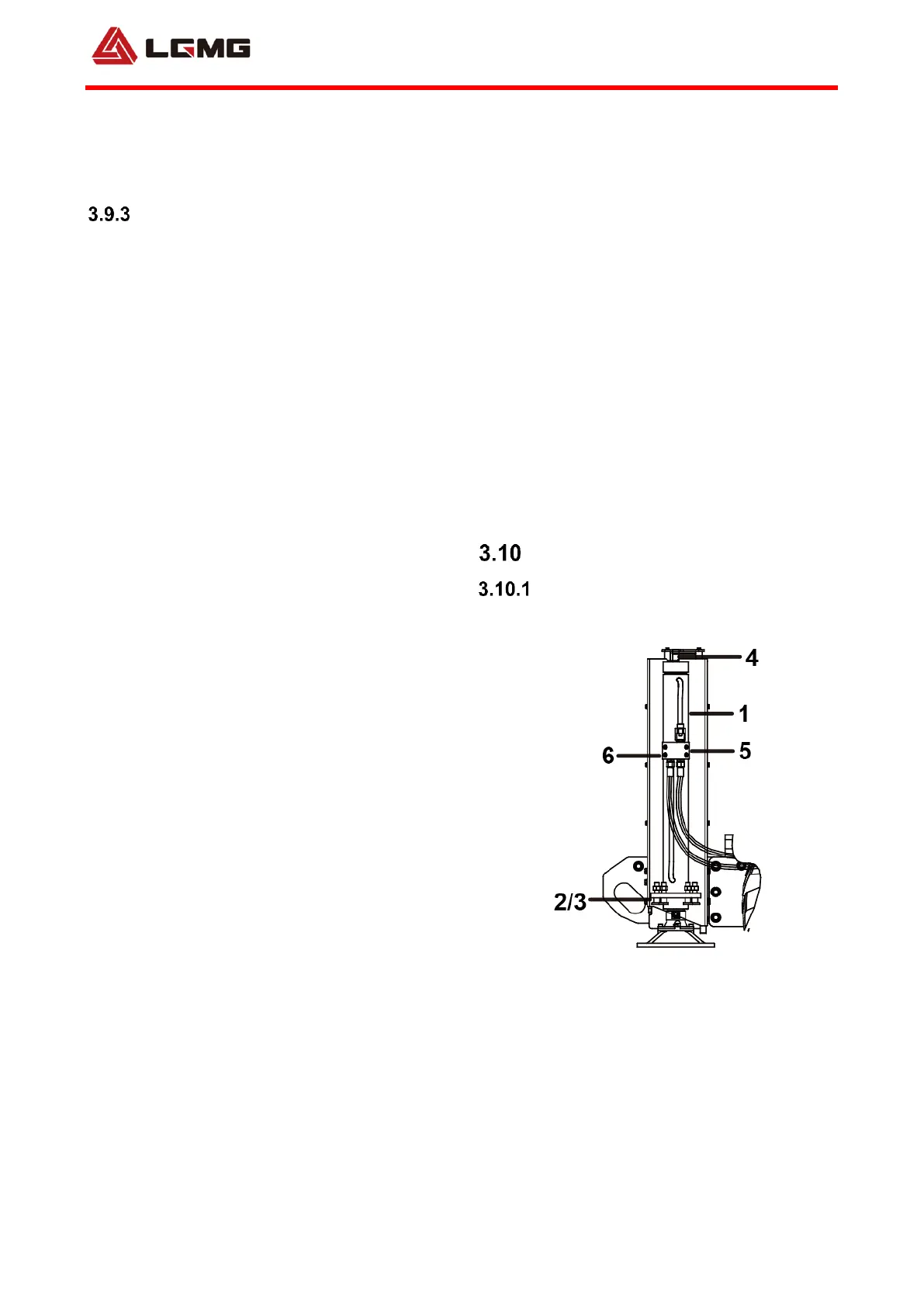

Outrigger assembly

Assembling the outrigger

cylinder

Fig. 3.51 outrigger cylinder

1. Outrigger cylinder 2. Outrigger cylinder

mounting bolt 3. Nut 4. Outrigger cylinder guide

stud 5. Outrigger solenoid valve ST5128-AB00 6.

Screw

1. Install part 1 to the mounting positions on both

sides of the support beam with parts 2 and 3,

and tighten it to the specified torque; apply

AT262 thread locker to bolts before installation;

Loading...

Loading...