Page 38 of 295

Warnings

• All IC (Integrated Controls) versions are not compliant for Medical use.

• Do not sideload the actuator.

• Only use the actuator within specified working limits.

• Always use steel backfixture for LA23 over 1500N and for pull loads.

• When mounting the LA23 in the application ensure that the bolts can withstand the wear and that they are secured safely.

• The B and G 24V motors must only be used with their respective control box types.

- Motor type A: 12V

- Motor type B: 24V motor which must be used with JUMBO; CBJ1/2, CBJC and CBJH or generally in applications which are mainly driven with battery

- Motor type G: 24V motor which must be used with OpenBus

TM

control boxes; CB20, CB16, CB6S, CA30, CA40, CO61

• If an actuator with stroke length below 50 mm is used, and the electrical end-stop switch fails, please be aware that the distance before reaching

the mechanical end-stop will be prolonged. The extra distance will be 50 mm minus actual stroke length. I.e. If an actuator with 20 mm stroke

length is used and the switch fails, it will travel an additional 30 mm before reaching the mechanical end-stop. Please make sure that the

application can withstand this in a safe way.

• Instruction concerning the turning of the piston rod eye. When mounting and taking into use, it is not

permitted to make excessive turns of the piston rod eye. In cases where the eye is not positioned correctly,

it is permitted to first screw the eye down to its bottom position, at a maximum torque of 2 Nm (1), and

thereafter a maximum half turn outwards again (2).

The item numbers for ordering the Cable Lock are:

• Item number: 0231007 (light grey) for one cable lock (1 piece).

• Item number: 0231037 (black) for one cable lock (1 piece).

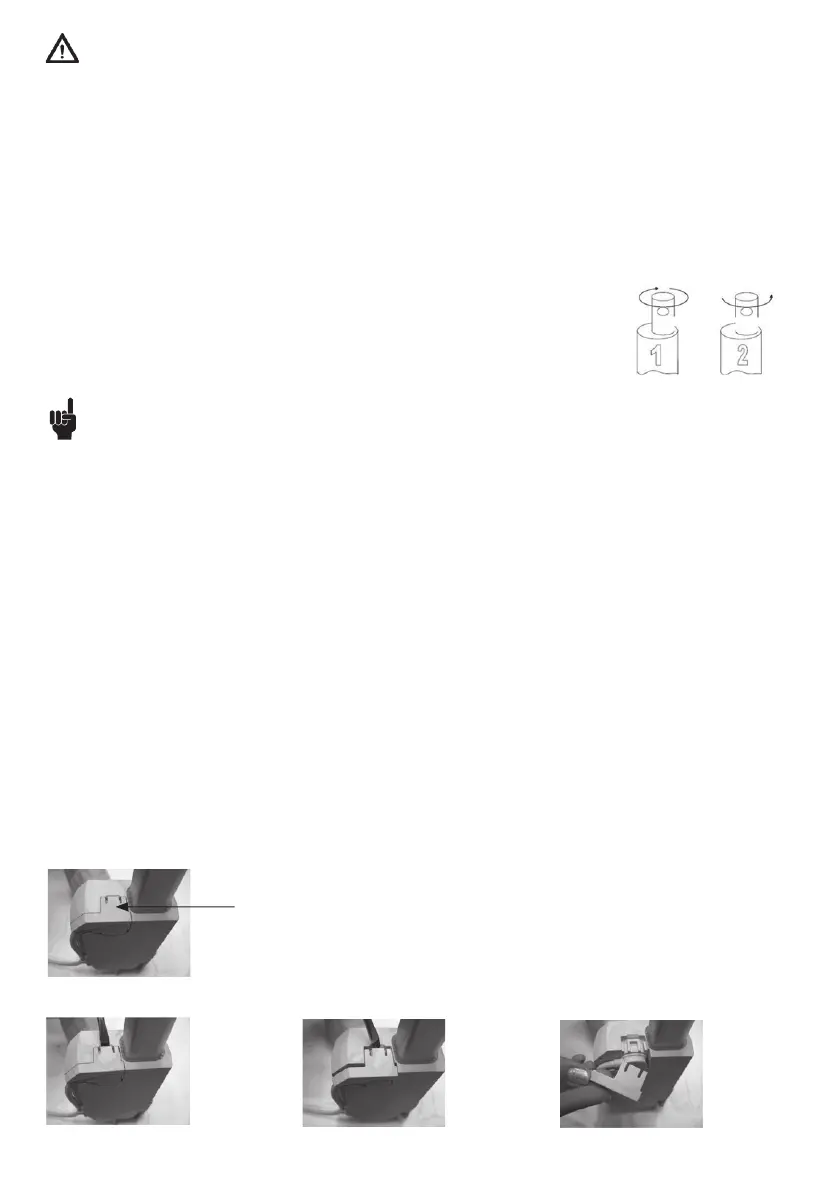

Below you see an instruction in how to mount and remove the cable lock from LA23.

a) Mount a cable lock:

Push down until the cable lock clicks into place.

Step 1:

Insert e.g. a screw-

driver at a 45 °C

angle as illustrated.

Step 2:

Turn the screwdriver

to release the cable

lock.

Step 3:

Now the cable lock

can be removed by

hand.

b) Cable lock removal

Note: When a cable lock has been removed, it is recommended to replace it with a new.

Recommendations

• Do not place load on the actuator housing and do prevent impact or blows, or any other form of stress to the housing.

• Ensure that the cable lock is mounted correct.

• Ensure that the duty cycle and the usage temperatures for LA23 actuators is respected

• Ensure that the cable cannot be squeezed, pulled or subjected to any other stress.

• The LA23 is not suitable for use in outdoor applications where it can be exposed to sun and rain.

If outdoor use cannot be avoided, it is very important that the LA23 is mounted in a position where it is well shielded. It is up to the customer to

provide the shielding. Furthermore, it will be good practice to ensure that the actuator is fully retracted in the “normal” position. The reason is that

there will be a vacuum inside the actuator if it is extended which over time can lead to water entering the actuator.

• The B and G 24V motors must only be used with their respective control box types.

• Not acceptable: B motor with OpenBus™ control boxes!

Reason: The actuator will be too strong, it will run too fast, be noisy and only have a short lifetime. The actuator will not live up to what we promise.

• Not acceptable: G motor with 24V supply!

Reason: The actuator will be too weak, this means it will only run slowly, not be able to lift as much in the cold and under low current conditions.

The actuator will not live up to what we promise.

Loading...

Loading...