Do you have a question about the Lincoln Electric K1419-4 and is the answer not in the manual?

Precautions to prevent electrocution from welding equipment.

Fire and explosion prevention measures during welding and cutting.

Safety precautions for equipment powered by an engine.

Safety measures to protect eyes and skin from arc rays.

Safety precautions for handling compressed gas cylinders.

Hazards associated with welding fumes and gases and ventilation requirements.

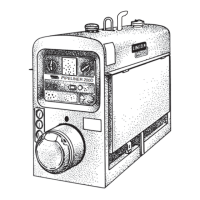

Detailed technical specifications for the RANGER® 10,000 welder.

Detailed technical specifications for the RANGER® 10,000 PLUS welder.

General safety measures to be observed during installation.

Information on the auxiliary power output capabilities of the welder.

Permissible current limits for simultaneous welding and auxiliary power loads.

Proper procedures for grounding the welder for electrical safety.

Extra safety measures to ensure safe operation.

Basic steps and information for operating the welder.

Specifications and information regarding the welder's output capabilities.

Procedures for starting and stopping the engine safely.

General guidelines for different welding processes.

Procedures and settings for stick welding.

Explanation of the welder's controls and their functions.

Procedures and settings for TIG welding with the optional module.

Procedures and settings for wire feed welding.

Critical safety measures before performing any maintenance tasks.

Step-by-step instructions for changing the engine oil.

Explanation of the main electrical and mechanical components and their interaction.

How rotor field feedback influences auxiliary power output.

How the weld winding, reactor, and range switch control welding current.

Function of the output bridge, choke, and polarity switch in delivering power.

Instructions on how to effectively use the troubleshooting guide.

Troubleshooting for constant voltage (CV) welding output issues.

Troubleshooting for engine starting, shutdown, and power output problems.

Troubleshooting steps for a cold welding arc.

Procedures for removing and replacing the engine and rotor.

| Brand | Lincoln Electric |

|---|---|

| Model | K1419-4 |

| Category | Welding System |

| Language | English |

Loading...

Loading...