Do you have a question about the Lincoln Electric K2481-1 and is the answer not in the manual?

| Brand | Lincoln Electric |

|---|---|

| Model | K2481-1 |

| Category | Welding System |

| Language | English |

Warnings regarding emissions and general arc welding safety.

Discusses EMF effects, pacemaker interference, and exposure mitigation.

Details the risks of electric shock and necessary protective measures.

Covers eye/skin protection from arc rays and health risks from fumes/gases.

Addresses risks from sparks, flammable materials, and gas cylinders.

Details safety requirements for electrically powered equipment.

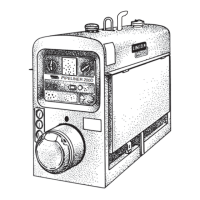

Details electrical and physical specs for 180A and 140A models.

Details electrical and physical specs for 125A models.

Covers essential safety rules to follow during installation.

Covers site selection and placement guidelines for the welder.

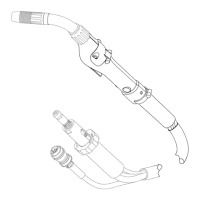

Identifies included components for 140A and 180A models.

Identifies included components for the 125A flux core unit.

Describes welder capabilities and defines common welding terms.

Explains the machine's main controls and their functions.

Lists items and steps for setting up flux-cored welding.

Details how to connect cables and load the wire spool.

Lists items and steps for setting up MIG welding.

Guides on connecting shielding gas cylinders for MIG welding.

Explains setup for aluminum welding using a spool gun.

Lists optional kits like Spot Timer, Innershield, and Spool Gun.

Describes utility carts for storing and transporting the welder.

Covers safety, compartment cleaning, motors, and wire reel spindle.

Details cleaning and maintenance for the welding gun.

Explains maintenance and replacement for gun consumables.

Explains the methodology for identifying and resolving machine malfunctions.

Lists common issues like output, feeding, gas flow, and welding problems with solutions.

Provides the electrical schematic for the wire feeder welder.

Displays the physical dimensions of the wire feeder welder unit.

Loading...

Loading...