Do you have a question about the Lincoln Electric BURNY KALIBURN Spirit II 150 and is the answer not in the manual?

| Brand | Lincoln Electric |

|---|---|

| Model | BURNY KALIBURN Spirit II 150 |

| Category | Welding System |

| Language | English |

Essential safety information for operators, observers, maintenance personnel, and those nearby.

Guidance on protecting against hazardous ultraviolet radiation emitted during plasma cutting.

Recommendations for ear protection due to high noise levels generated during plasma cutting.

Measures to ensure adequate ventilation and use of breathing equipment to avoid toxic fumes.

Guidelines and precautions to protect against fatal electric shock hazards.

Safety measures to prevent fires caused by sparks or flammable materials during cutting.

Safety guidelines for handling compressed gases and preventing explosions.

Minimizing exposure to electric and magnetic fields for individuals with medical devices.

Index of safety practices and relevant publications for plasma arc cutting.

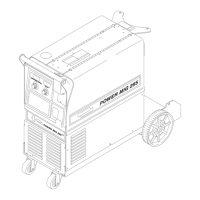

Overview of the Spirit II 150 system's capabilities, torch, and enclosure ratings.

List of standard and optional components included with the Spirit II 150 system.

Detailed electrical, environmental, and physical specifications for the power supply unit.

Information on the required torch coolant solution and its maintenance.

Dimensional and weight specifications for the Manual Gas Console (MGC).

Details on plasma gas types, shield gas types, flow rates, and inlet pressures.

Dimensional and weight specifications for the Impulse Start Console (ISC).

Specifications and diagrams for the Torch and 2-Gang Manifold assemblies.

Dimensional specifications for the 5-Gang Manifold assembly.

Chart detailing sound pressure levels at different distances from the torch.

Procedures for inspecting the system upon receipt and handling of defective or missing parts.

Guidelines for physically locating and mounting the Power Supply, MGC, ISC, and Manifolds.

Overview of system interconnection diagrams and optional Inova height control connections.

Instructions for connecting primary power, including disconnect switch and fuse recommendations.

Steps for connecting the power supply output leads to the impulse start console and work table.

Procedure for connecting the ISC control cable and ground connections.

Steps for connecting the coolant supply and return hoses to the impulse start console.

Instructions for connecting the torch leads to the impulse start console.

Procedures for connecting the torch leads to the torch base.

Step-by-step guide for connecting torch gas hoses to console, base, and manifold assemblies.

Instructions for connecting air, oxygen, nitrogen, and H17 gas supply lines to the MGC.

Procedure for connecting the plasma power supply to the MGC using CAN communication.

Details on interfacing the Spirit system with a CNC cutting machine.

Step-by-step guide for filling the system's cooling reservoir with approved coolant.

Description of MGC controls: OFF Button, Up/Down/Select Buttons, Display, and Regulator Knobs.

Procedure for configuring the system, including process, current, and gas selection.

Instructions on how to switch the system from cutting to marking mode.

Procedure to check if input gas pressures are within the acceptable operating range.

Steps to initiate cutting or marking after system setup and sequence overview.

Techniques to prevent torch damage when piercing thick materials.

Methods for starting cuts on thick materials using moving pierces or edge starts.

Guidelines for identifying and correcting issues affecting cut quality.

Procedure to view the last ten system error codes via the MGC.

How to display hardware and software version, and serial numbers for components.

Instructions for changing the display language on the MGC.

Procedure for adjusting the contrast of the MGC display.

Step-by-step guide for attaching and detaching the torch head, including o-ring lubrication.

Detailed instructions for removing and installing torch consumables like nozzles and electrodes.

Guidelines and best practices to extend the lifespan of torch consumable parts.

Table outlining parts inspection points and corresponding corrective actions for consumables.

Charts showing recommended consumables for different materials and amperages.

Index and charts providing starting parameters for cutting various materials and thicknesses.

Recommended monthly checks for the Power Supply, including cleaning and connection verification.

Maintenance tasks for the MGC, including cleaning and checking hose connections.

Inspection and maintenance of torch leads, gas hoses, and fittings for leaks and damage.

Checking fittings and connections on the Impulse Start Console for security and sealing.

Ensuring the work ground lead is securely fastened and free from corrosion.

Procedure for flushing and replacing the torch coolant and deionization cartridge.

Explanation of diagnostic LEDs and OPTO LEDs on the DSP board for troubleshooting.

Description of DSP indicator illumination sequence during system startup and operation.

Comprehensive list of system error codes, their short descriptions, and power supply long descriptions.

Common problems and their possible causes, with troubleshooting steps.

Step-by-step guide for testing chopper assemblies in the power supply.

Component reference diagram for the right side of the Power Supply unit.

Component reference diagram for the left side of the Power Supply unit.

Component reference diagram for the top view of the Power Supply unit.

Component reference diagram for the cooling section of the Power Supply unit.

Component reference diagram for the right side of the Manual Gas Console.

Component reference diagram for the left side of the Manual Gas Console.

Component reference diagram for the Impulse Start Console.

List of parts for Torch and Manifold assemblies, including handles, heads, and o-rings.

Part numbers and available lengths for shielded torch leads.

Part numbers for CAN communication cable and termination plug.

Part numbers and available lengths for 2-Gang and 5-Gang manifold control cables.

Part numbers and lengths for gas hose packages compatible with the MGC.

Part numbers and available lengths for coolant and power leads.

Part numbers and available lengths for the work ground lead.

Part numbers and available lengths for optional oxygen supply gas hoses.

Part numbers and available lengths for optional nitrogen supply gas hoses.

Part numbers and available lengths for optional air supply gas hoses.

Part numbers and available lengths for optional H17 supply gas hoses.

Part number and available lengths for the CII cable for external Inova option.

Part number and available lengths for the FII cable for internal Inova option.

Part number and available lengths for the JII cable for internal Inova option.

Diagrams showing component locations on Power Supply DSP PCB quadrants.

Introduction to the optional Inova system for arc voltage control integrated with the Spirit II.

Distinguishing internal Inova console plugs from other connections on the power supply.

Methods for connecting the internal Inova console to protective earth ground.

List of PCBs and components for the internal Inova option.

Diagram showing the location of internal Inova option components in Spirit II 150 & 275.

Continuation of component location diagrams for Spirit II 150 & 275.

Diagram showing the location of internal Inova option components in Spirit II 400.

Continuation of component location diagrams for Spirit II 400.

Information on the system's compliance with European EMC standards and classification.

User responsibility for installation and resolving detected electromagnetic disturbances.

Recommendations for reducing emissions via mains supply filtering, shielding, and maintenance.

Routine maintenance requirements for ensuring proper EMC performance.

Considerations for bonding metallic components to reduce shock risk and improve compatibility.

Methods for earthing the workpiece to potentially reduce emissions, with safety considerations.

Using selective screening and shielding for cables and equipment to alleviate interference.

Loading...

Loading...