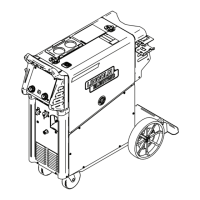

Do you have a question about the Lincoln Electric Power-Arc 5500 and is the answer not in the manual?

| Max Open Circuit Voltage | 80V |

|---|---|

| Input Frequency | 50/60 Hz |

| Power Factor | 0.93 |

| Efficiency | 85% |

| Processes | Stick, TIG |

Hazards associated with arc welding, including injury and death risks.

Warnings and precautions regarding electrical shock from the equipment.

Risks from welding fumes and gases, emphasizing ventilation.

Crucial safety instructions to read before starting installation procedures.

Details on weld output terminals, receptacles, and recommended welding cable sizes.

Procedures for connecting welding cables and proper machine grounding.

Essential safety guidelines to follow before operating the equipment.

Details on the machine's rated amperage, duty cycle, and electrode compatibility.

Safety and operational advice for running the gasoline engine.

Step-by-step instructions for starting the engine in cold and hot conditions.

How to use the machine as an auxiliary power supply, including load management.

Detailed steps for performing welding tasks with the machine.

Key techniques for welding: position, striking arc, arc length, and speed.

Essential safety warnings before performing any maintenance tasks.

Guidelines for checking, changing, and maintaining engine oil levels.

Instructions on how to effectively use the troubleshooting section to diagnose issues.

Common problems related to no generator power or welding output.

Troubleshooting steps when generator power is available but welding fails.

Issues with erratic engine running, stopping, sputtering, or not starting.

Specific causes and solutions for the engine failing to start.

Loading...

Loading...