Page Number - 3

Form 403693

FlowMaster™ Rotary Driven Electric Pump

Installing the Pump

Typical installation is shown only as a guide for selecting and

installing system components. Contact your Lincoln

Industrial representative for assistance in designing a

system to suit your specic needs.

The pump was tested in light weight oil which was left in to

protect the pump from corrosion. Flush the pump before con-

necting it to the system to prevent contamination of the grease

with residual oil.

1. Mount the pump securely on the drum cover so that it

cannot move or vibrate during operation.

2. Connect material supply line to the pump outlet. Install a

safety unloader [such as 272722 (4000 PSI, 276 bar) or

272572 (2500 PSI, 172 bar)] to outlet on opposite side of

the pump.

3. Install high pressure shut-off valve in the material supply

line. (Required)

Mount the pump securely on the drum cover. Failure to do

so could result in personal injury and equipment damage.

Always install a relief valve in the pump outlet to insure pump

pressure is below 5,000 PSI (2,500 PSI for Model 85569.

Use high pressure components to reduce risk of serious

injury including uid injection and splashing in the eyes or on

the skin.

is forced into the pump cylinder. Simultaneously, grease is discharged

through the outlet of the pump. The volume of grease during intake is

twice the amount of grease output during one cycle. During the upstroke,

the inlet check closes, and one half of the grease taken in during the pre-

vious stroke is transferred through the outlet check and discharged to the

outlet port. Typical output of the pump is shown on page 4.

Appropriate Use

• All pump models are exclusively designed to pump and

dispense lubricants using 24 VDC electric power.

• The maximum specication ratings should not be

exceeded.

• Any other use not in accordance with instructions will

result in loss of claims for warranty and liability.

Pump Performance and Specication

Operating Temperature, °F (°C)- -40 to +150 (-40 to 65)

Operating Voltage, VDC - 24 (18 MIN., 32 MAX)*

Motor, HP (kW) 1/2 (0.37)

Current draw, AMPS See tables 2, 3, 4, & 5

Output/pump cycle, in

3

(cm

3

) 0.07 (1.15)

Pump performance See table 1

Pump Outlets, In - 1/4” NPTF Female

Weight, Lbs (Kg) - 30 (13.3)

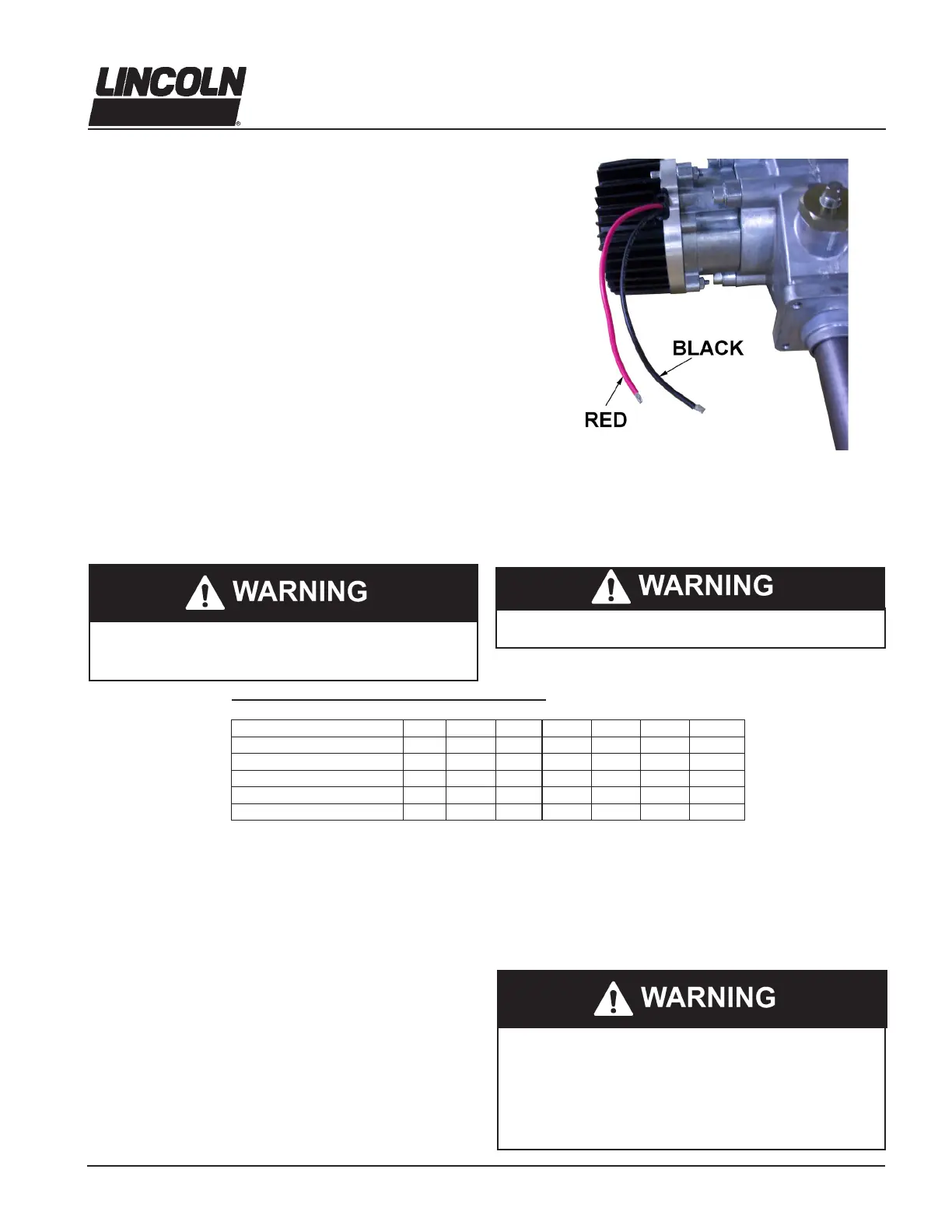

ELECTRIC PUMP PERFORMANCE SPECIFICATIONS

CUBIC IN/MIN Test conducted with Alvania NLGI#2 Grade Grease at 1000 psi Backpressure

TEMPERATURE DEG F (DEG C) 50 RPM 100 RPM 150RPM 200 RPM 250 RPM 300 RPM 350 RPM

80 (27) 3.5 7 10.5 14 17.5 21 24.5

40 (4) 3.5 7 10.5 14 17.5 21 24.5

20 (-7) 3 6 9 12 15 18 21

0 (-18) 3 6 9 12 15 18 21

-10 2.5 5 7.5 10 12.5 15 17.5

* Motor controller will shut motor off outside voltage limits.

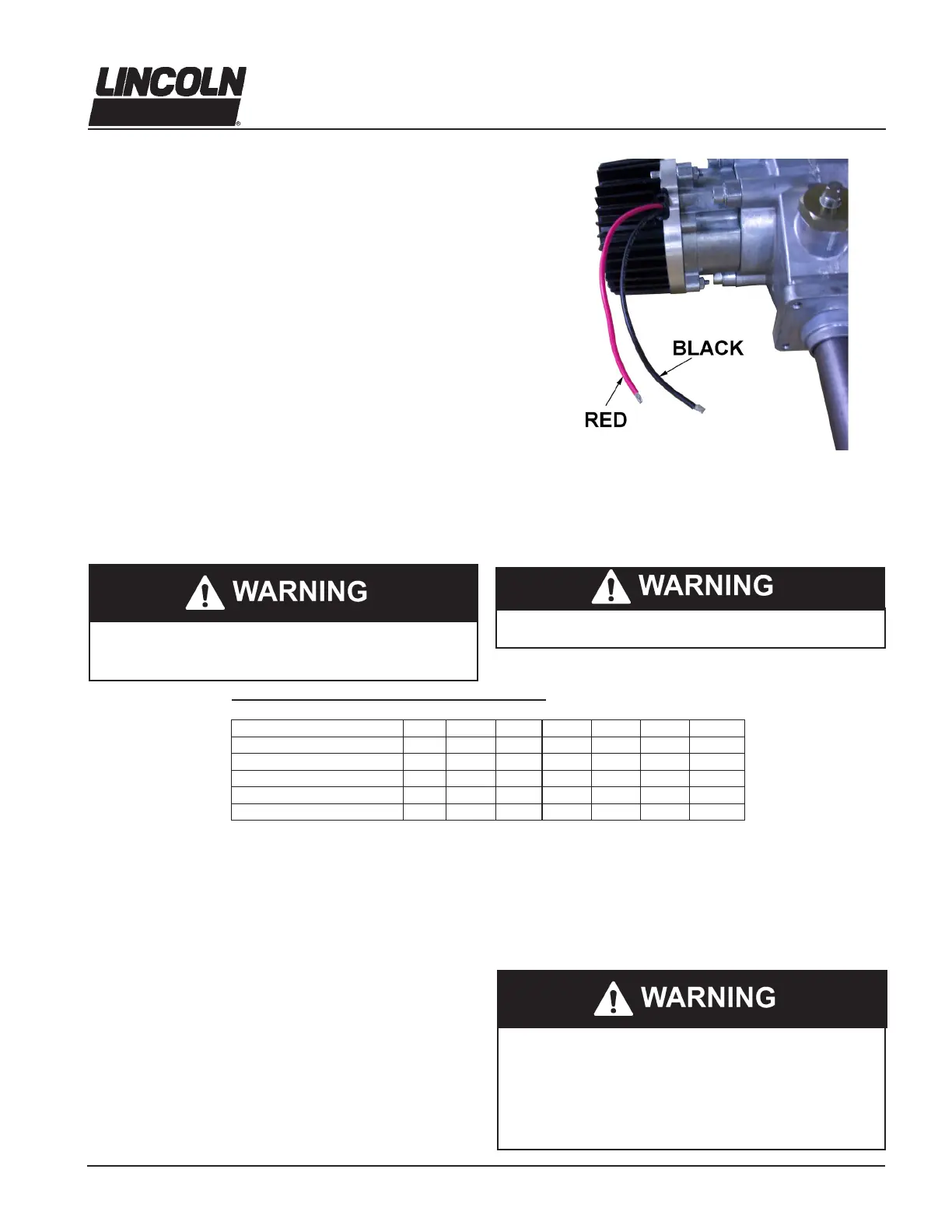

4. Wire the pump motor and vent valve (if used) as shown in

Illustration 1.

5. Connect power to motor leads. Be sure to connect red

motor lead to the positive side of the circuit (see Illustration

1A). The motor is polarity sensitive and will not run if im-

properly wired. Fuse the motor as recommended in Tables

2, 3, 4 & 5.

Table 1

ILLUSTRATION 1A

Pumps are not equipped with a high pressure shut-off valve.

Do not exceed maximum rated outlet pressure for these

pumps. Exceeding rated pressure may result in damage

to system components and personal injury.

Loading...

Loading...