Page Number - 5

Form 403693

FlowMaster™ Rotary Driven Electric Pump

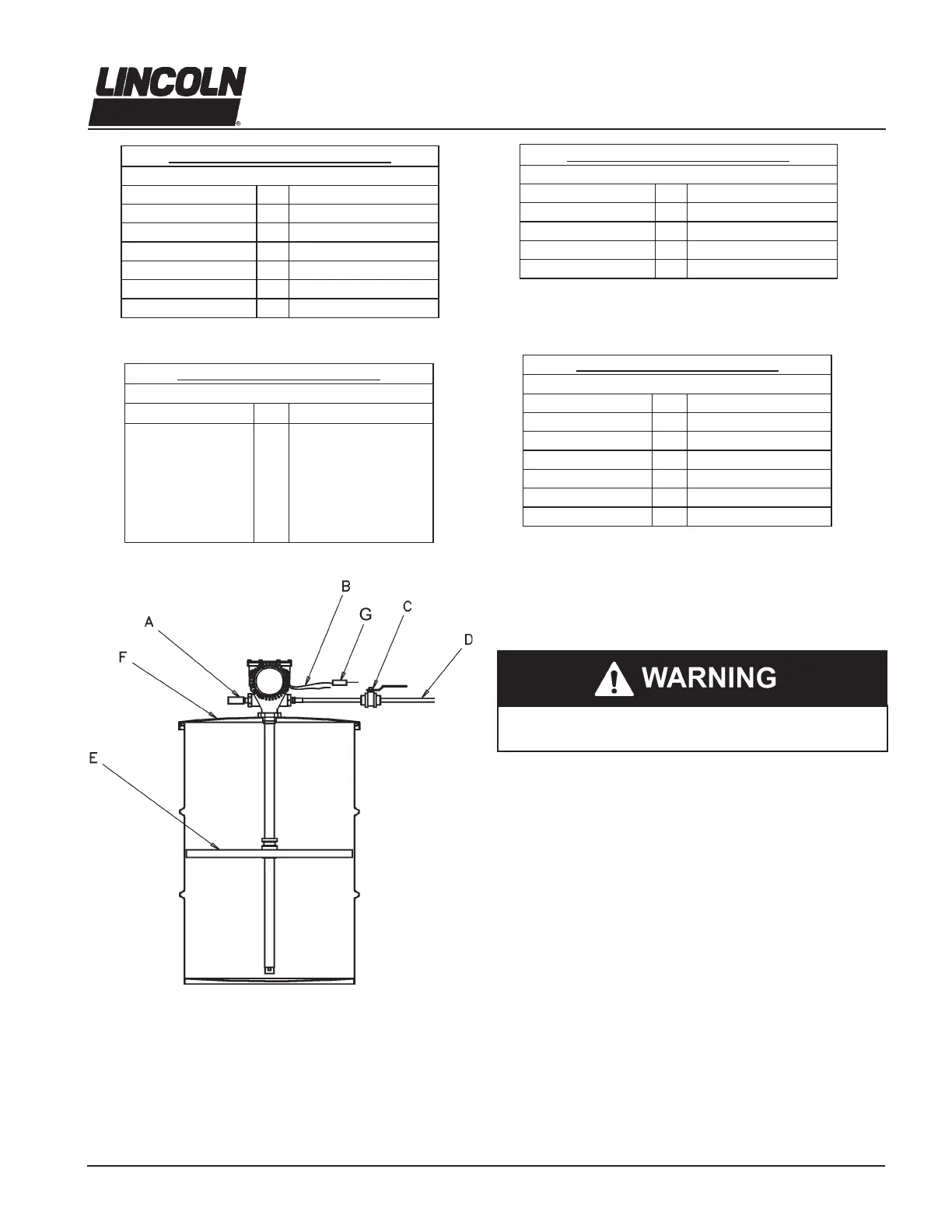

* A eld installed fuse of 5 amps is recommended.

ELECTRIC FLOWMASTER PUMP

24 VDC, 34:1 Gear Ratio, 2 Stage 85552 & 85553

Back Pressure (PSI) RPM Current Draw (AMPS)*

0 58.2 1.16

1000 57.6 1.57

2000 57.0 2.10

3000 56.5 2.62

4000 55.9 3.20

5000 55.4 4.20

* A eld installed fuse of 20 amps is recommended.

Table 2

Table 3

ELECTRIC FLOWMASTER PUMP

24 VDC 19:1 Gear Ratio, 2 Stage, 85554 & 85566

Back Pressure (PSI) RPM Current Draw (AMPS)*

0 105 1.28

1000 103 2.03

2000 101 2.96

3000 99 3.68

4000 98 4.83

5000 96 6.47

ELECTRIC FLOWMASTER PUMP

24 VDC, 5:1 gear ratio, 85567, 85568, 85591

BACK PRESSURE (PSI) RPM CURRENT DRAW (AMPS)*

0 375 2

1000 350 4.5

2000 325 7.3

3000 300 9.6

4000 280 12

5000 250 15.3

* Fuse for 6 amps

* Fuse for 10 amps

Table 4

Table 5

ELECTRIC FLOWMASTER PUMP

24 VDC, 17.8:1, gear ratio, 2-stage 85569

BACK PRESSURE (PSI) RPM CURRENT DRAW (AMPS)*

0 107 1.28

1000 105 2

2000 103 2.75

2500 100 3.2

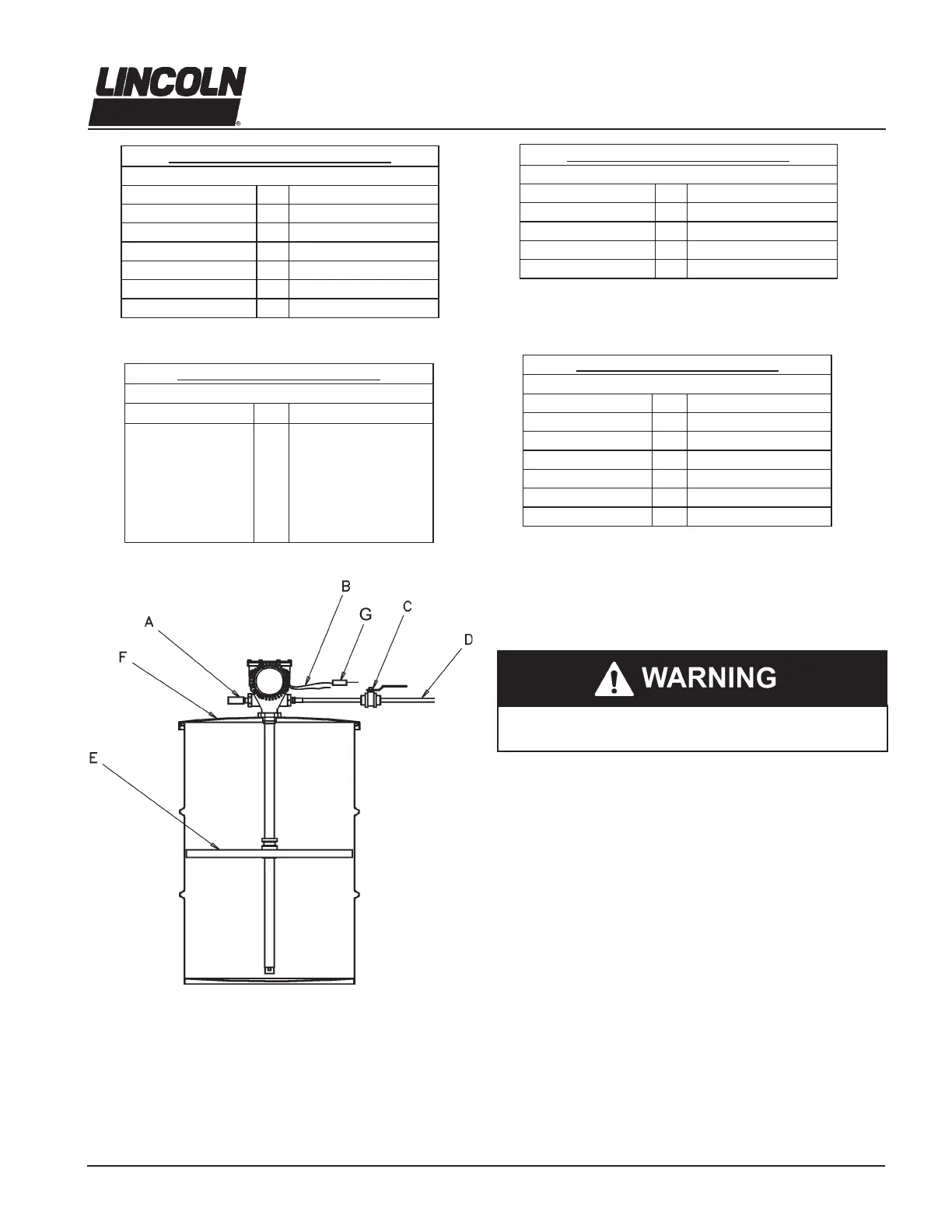

Illustration 2

A - Safety Unloader 272722 or 272572

B - 24 VDC from Controller

C- Outlet Shut-off Valve

D - Material Supply Line

E - Follower Plate (85492 for 120 lb.)

F - Drum Cover (84616 for 120 lbs.)

G - Field Installed Fuse

Operation

All pumps are set to run at full speed. Do not change the

settings for the pump until after the start up procedure.

1. Remove the pump outlet line.

2. With the pump in a full container of lubricant, energize the

pump. Make sure all air has been expelled from the pump

and even lubricant ow is achieved.

3. Reattach the pump outlet line. Never allow the pump to run

dry of lubricant. Monitor the supply lubricant level and rell

when necessary.

Loading...

Loading...