object which might interfere with them.

If any wire becomes wrapped around the wheel

hubs or bearings, this must be removed. Failure

to do so may result in rapid wear to the wheels.

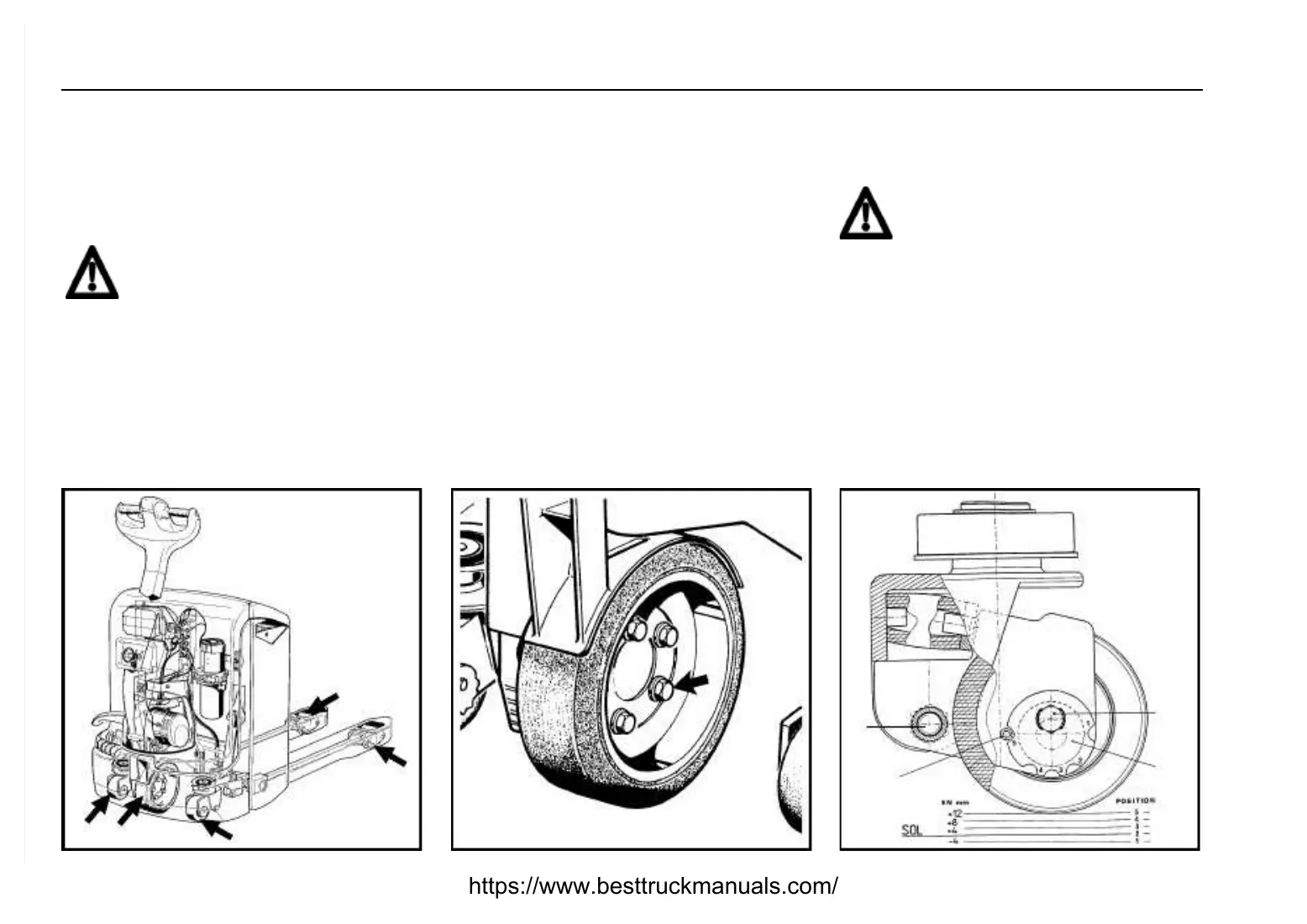

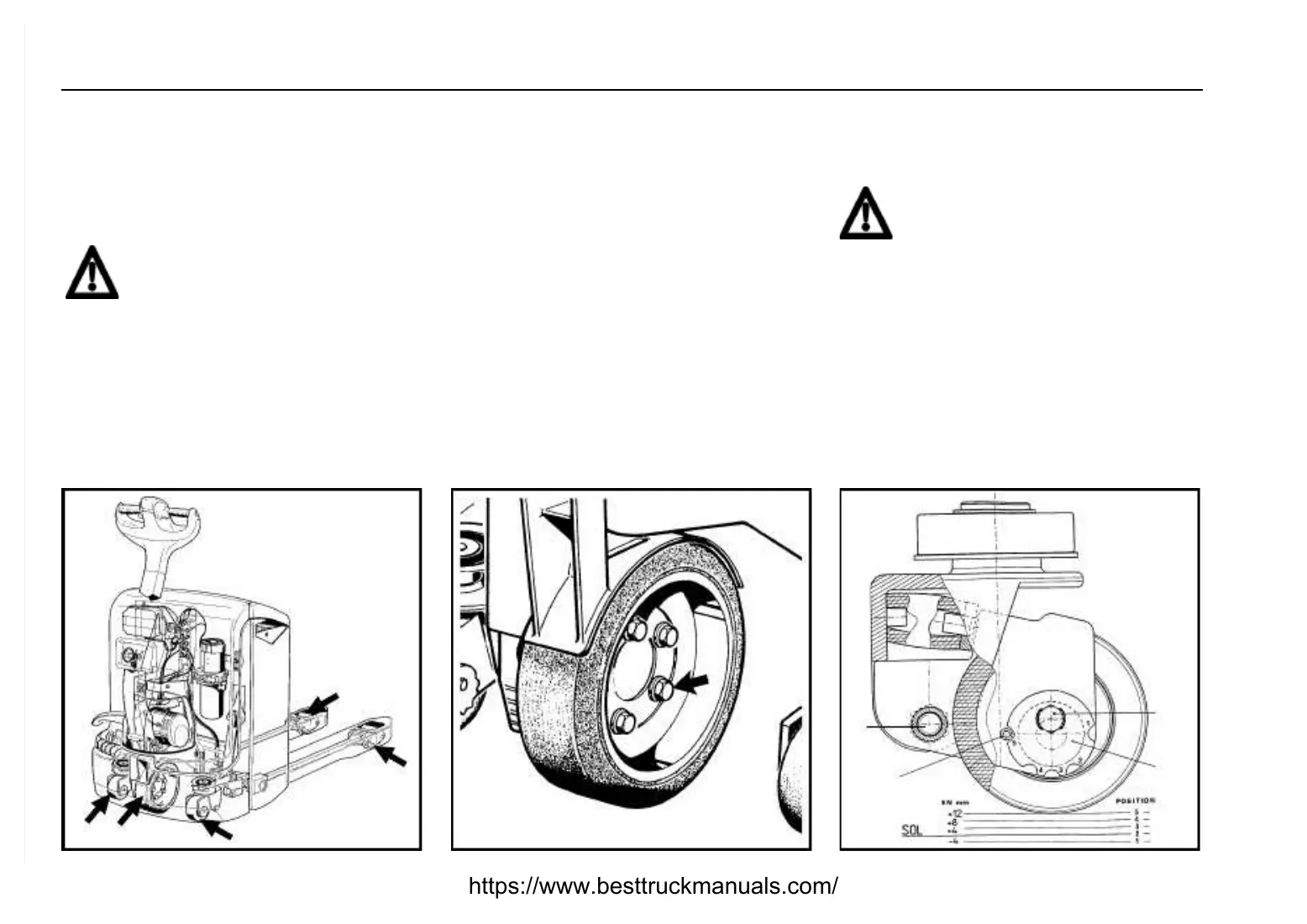

Fitting and adjustment of the stabiliser wheel

to be able to turn the eccentric assembly and the wheel

spindle using the other bolt.

adjacent to the locking pin (2)

If, in spite of all precautions, water finds its way into the

motors, the truck must be run to prevent the formation of

rust, so that it dries under its own heat. Motors may also

be dried using compressed air.

If the truck is cleaned frequently, it will also need fr

the ground, and chock it up

Recommended torque setting: 80 Nm

wheels. Recommended torque setting: 50 Nm

Checking the condition of the wheels

the ground, and chock it up

Disconnect the battery before commencing cleaning.

Steam jets or highly detergent products must be used only

with great care, as they dilute the grease in lifetime-

lubricated bearings. Since re-greasing is not possible,

these cleaning methods can result in wea

When using cleaning equipment, do not expose

electrical circuits, motors or switch panels to

direct jets. Protect these components before

When using compressed air, first remove any stubborn

dirt using a cold detergent.

Before commencing lubrication tasks, clean oil filling

holes and surrounding areas in particular, as well as

grease nipples. Dry the truck after cleaning.

https://www.besttruckmanuals.com/

Loading...

Loading...