HSLG Slide Gate Operator Installation Guide - 4 - P1220 X14

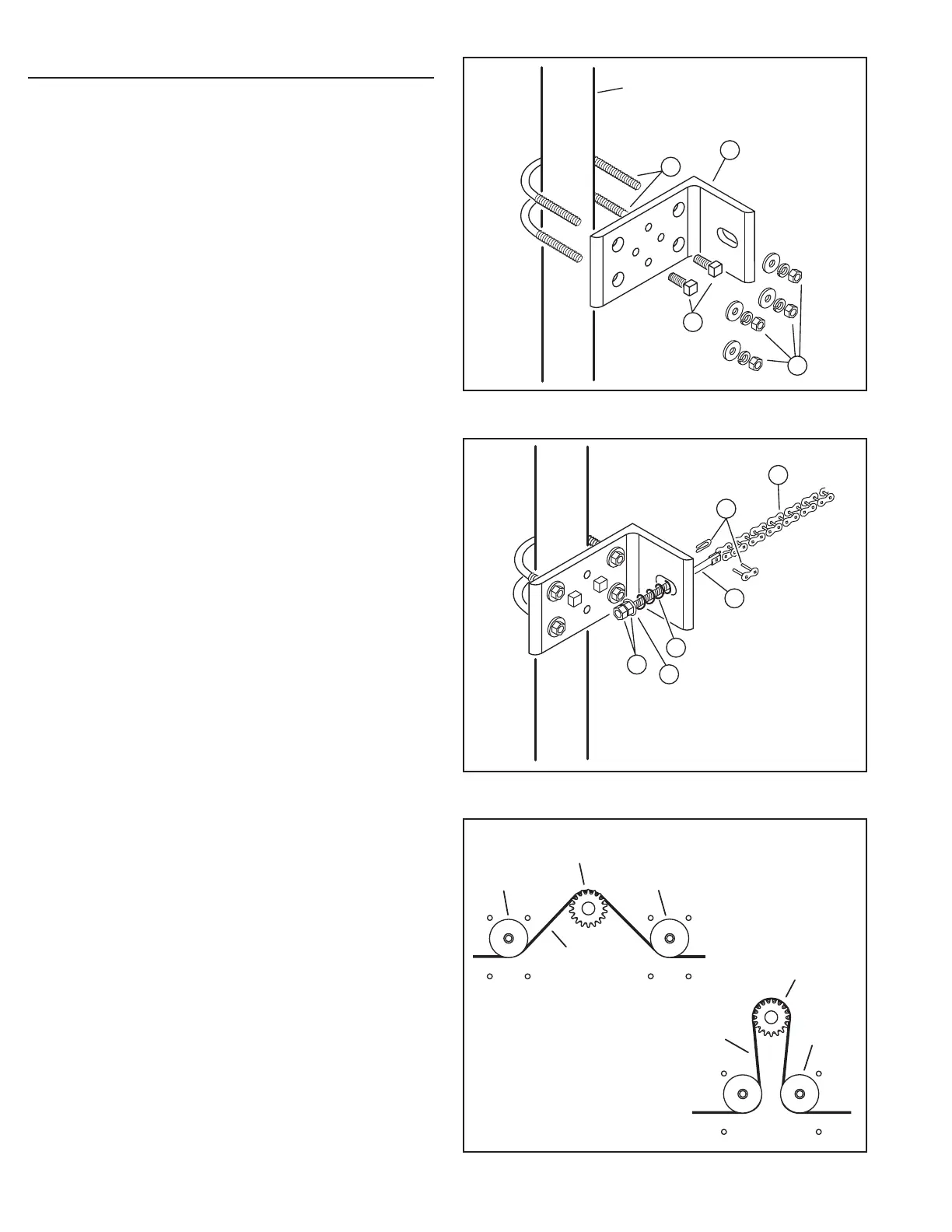

Gate Bracket and Chain Assembly

✓ NOTE: The item numbers shown in these illustrations

are for reference only. For the actual part numbers, refer

to the parts lists in the rear of this manual.

Assemble a gate bracket (1) to the front edge of the gate, using

two U-bolts (2), and mounting hardware (3). Before tightening down

completely, be sure the bracket is parallel to the gate. Tighten the U-bolt

hardware the rest of the way, then screw the square head bolts (4) into

the threaded holes in the gate plate until they bottom out against the

gate. These will help keep the bracket from twisting on the pipe.

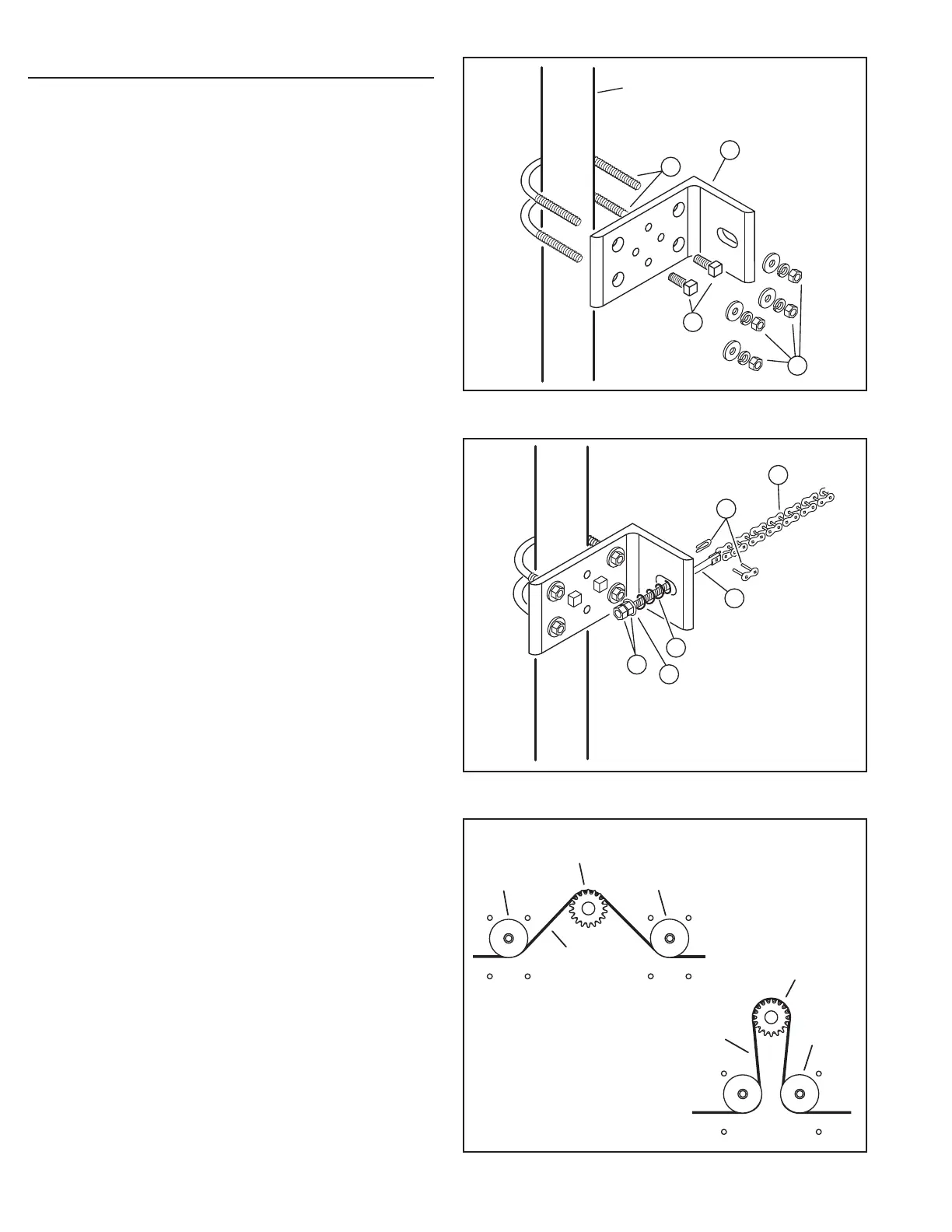

Slide a threaded chain pin (5) through the bracket as shown, with spring

(6), at washer (10), and two hex nuts (7). Attach one end of the drive

chain (8) to the chain pin using master link (9) and begin unrolling the

chain toward the operator.

Remove the rain cover from the back of the slide gate operator. Carefully

thread the drive chain under the rst idler, over the drive sprocket, and

then under the last idler. Make sure you feed most of the chain through

the idlers and sprocket before attaching the chain to the back end of

the gate.

Assemble the other gate bracket on the rear edge of the gate, using

the same process as the front gate bracket. Once this is done, take the

other chain pin, spring and jam nuts and assemble with the end of drive

chain and the other master link.

At this point you should be able to adjust the chain tension by tightening

the jam nuts on each end. Approximately 1/4” to 3/8” of slack

per foot of drive chain is acceptable. Make sure the chain

does not drag on the ground, across the gate rollers or the idler frame

of the operator.

Additional mounting holes have been provided in the gate bracket for

installer convenience.

END OF GATE PIPE SHOWN

REFERENCE ONLY

1

2

3

4

Figure 3. Mounting Gate Bracket to Gate

Figure 4. Chain Pin and Chain Assembly

8

9

5

6

7

10

NOTE: IDLER CONFIGURATION

MAY APPEAR DIFFERENT DEPENDING

ON THE SLIDE OPERATOR MODEL

DRIVE

SPROCKET

DRIVE SPROCKET

IDLER

WHEEL

IDLER WHEEL

CHAIN

PATH

CHAIN

PATH

IDLER WHEEL

Figure 5. Chain Path

www.LinearGateOpeners.com | (888) 378-1053 | Sales@LinearGateOpeners.com

Loading...

Loading...