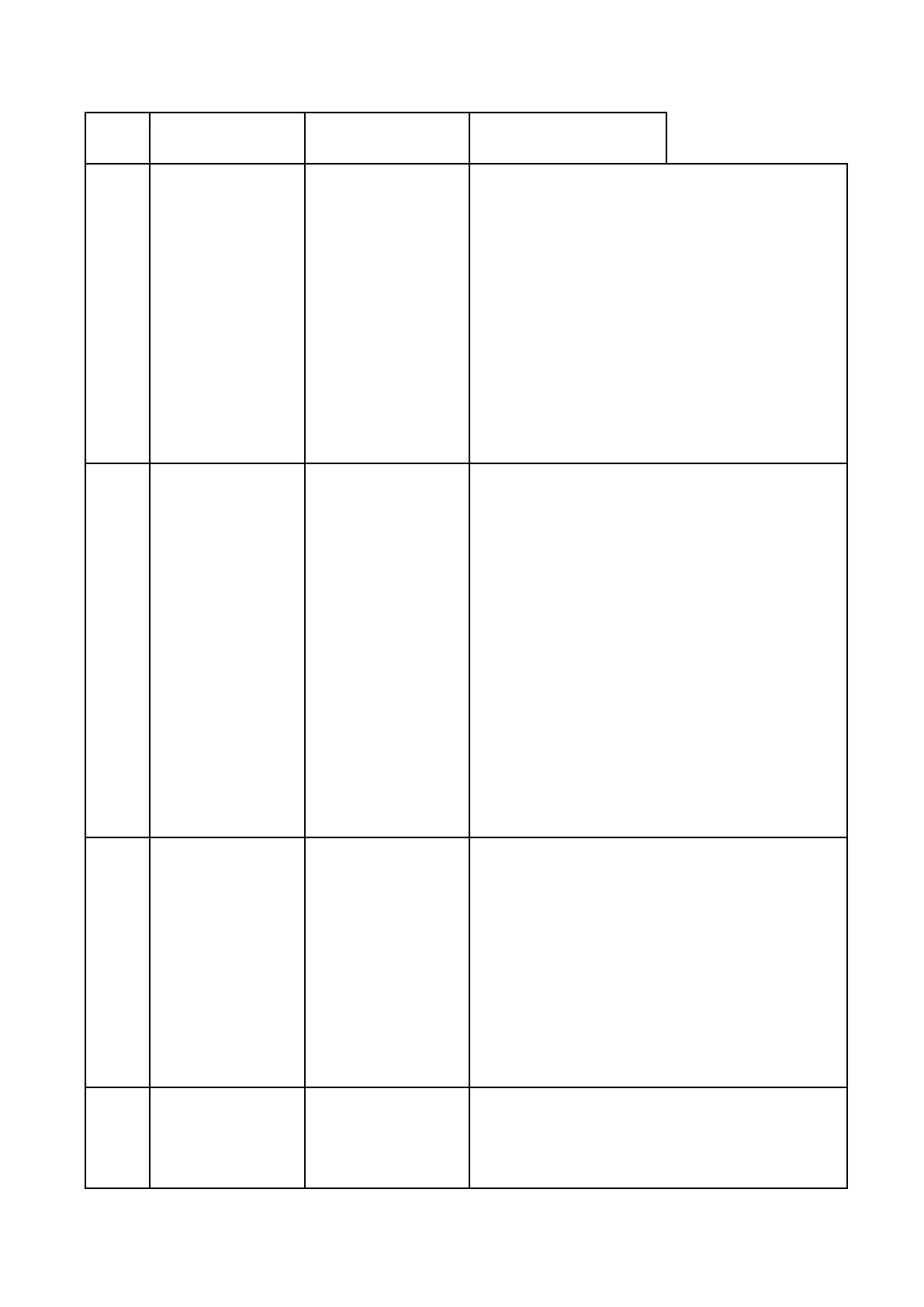

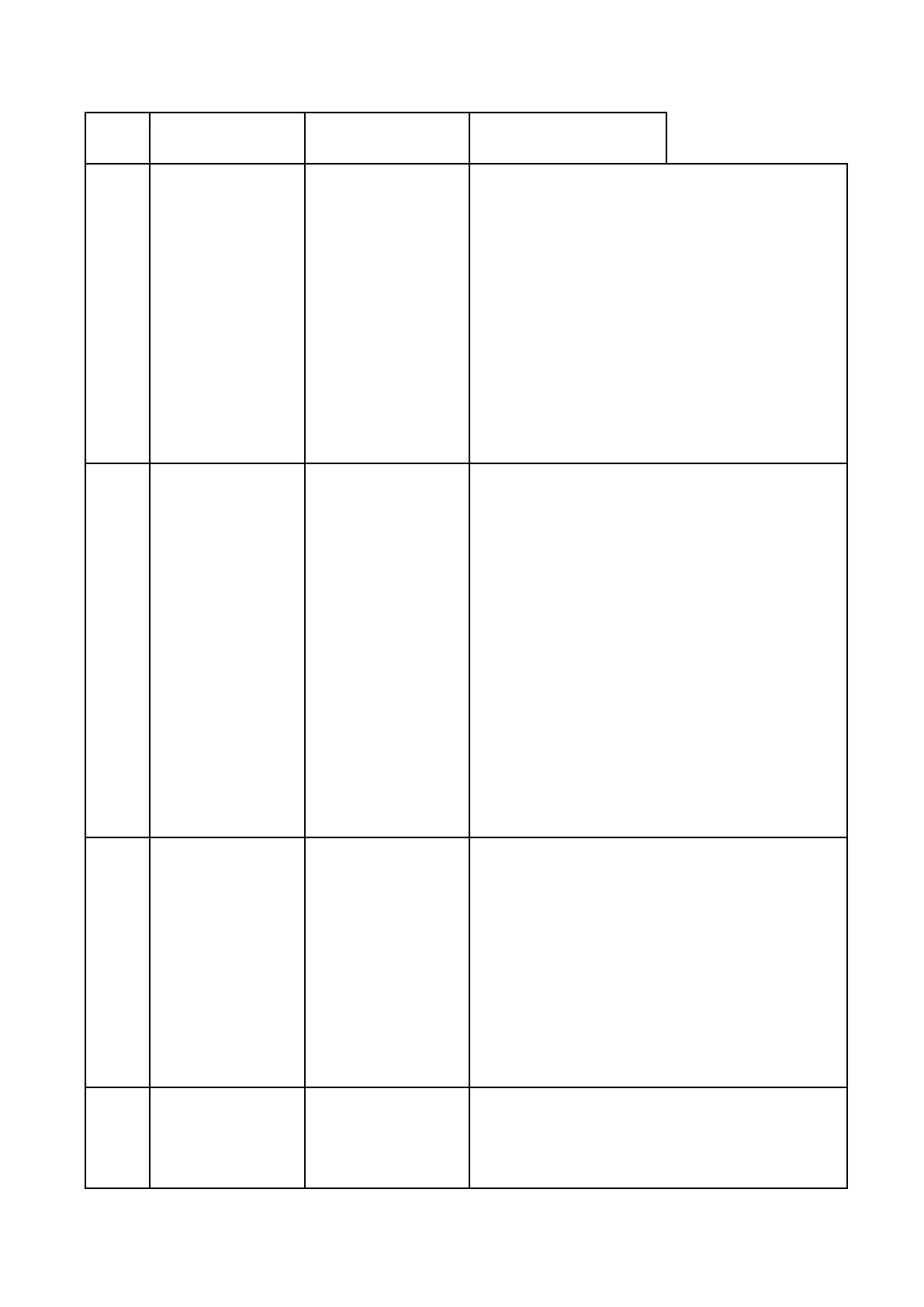

79

overvoltage

detection level

1.200 V class: 410

V

2.400 V class: 820

V( 740 V when d1-

01<400 )

output short circuit

3. Ground fault in

the output circuit

causes the DC bus

capacitor to

overcharge

4. Electrical signal

interference causes

drive malfunction

2. Check the motor power cable, relay

terminals and motor terminal box

3. Correct grounding shorts and reapply

power

4. Check the solutions for interference

suppression

»Check the control circuit lines, main circuit

lines and grounding wiring.

»If the MC is the source of interference,

connect a suppressor to it.

5. Reconnect the cable

6. Correct the wiring

Undervoltage

1.Voltage in the

DC bus fell below

the undervoltage

detection level

(P2-03)

2.200 V class: 190

V

3.400 V class: 380

V

( 350 V when d1-

01<400 )

1. Input power

phase loss

2. Loose wiring

terminals of drive

input power

3. Problem with the

voltage from the

drive input power

4. The drive main

circuit capacitors

are weakened.

5. The contactor or

relay on the soft-

charge bypass

circuit is damaged

1. Correct the drive input power wiring

2. Tighten the terminals

3. Check the voltage

a. Adjust the voltage according to the drive

input power specifications

b. Check the main circuit magnetic contactor if

there is no problem with the power supply

4&5. Turn on and turn off the power to see if

any problem occurs

Replace either the entire drive or the control

board if the problem continues to occur.

Contact the local distributor for more

information.

Undertorque

Detection 1

The current has

dropped below

the torque

detection level set

to P6-01 for

longer than the

time set to P6-02

1. Incorrect

parameter settings

2.Malfunction on

machinery side. Ex,

the machinery is

locked up

1. Reset P6-01 and P6-02

2. Ensure there is no problem on the

machinery side.

Baseblock

Drive output

interrupted by an

An external

baseblock signal

was input via one of

the multi-function

Check baseblock signal input timing and

external sequence

Loading...

Loading...