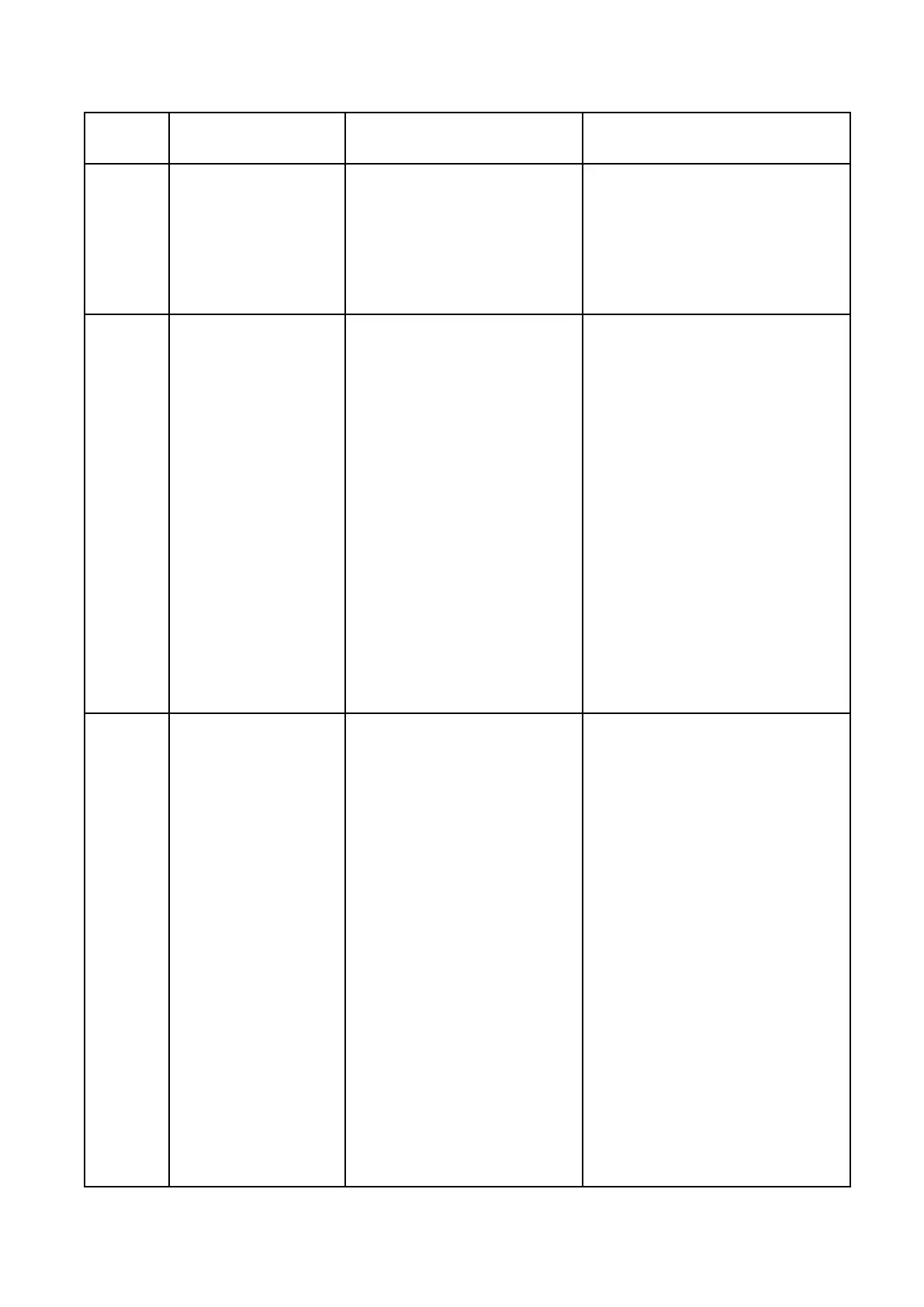

85

heat

2. Measure the output current

a. Reduce the load

b. Lower setting in C6-00

( Carrier Frequency Option )

3.Replace the cooling fan

Motor Overheat 1

The temperature

signal from motor

temperature sensor

via analog input

terminal A1 (E3-

01=20) exceeded the

overheat detection

level of the drive.

1. Incorrect motor

temperature input (terminal

MT) wiring

2. Fault on the machinery

(e.g., machinery is locked up)

3. Motor overheat

1. Check the load, acceleration /

deceleration time and cycle time

a. Reduce the load

b. Increase C1-00 to C1-03

(Acc./Dec. Time) settings

2. Adjust d1-02 to d1-09 (V/F

Characteristics)

Note: If the d1-02 and d1-09 are

set too low, the tolerance at low

speed will be reduced.

3.a. Check the setting for motor

rated current. Set d1-00 as per

the data written on the motor

plate.

b. Check if the motor cooling is

working properly.

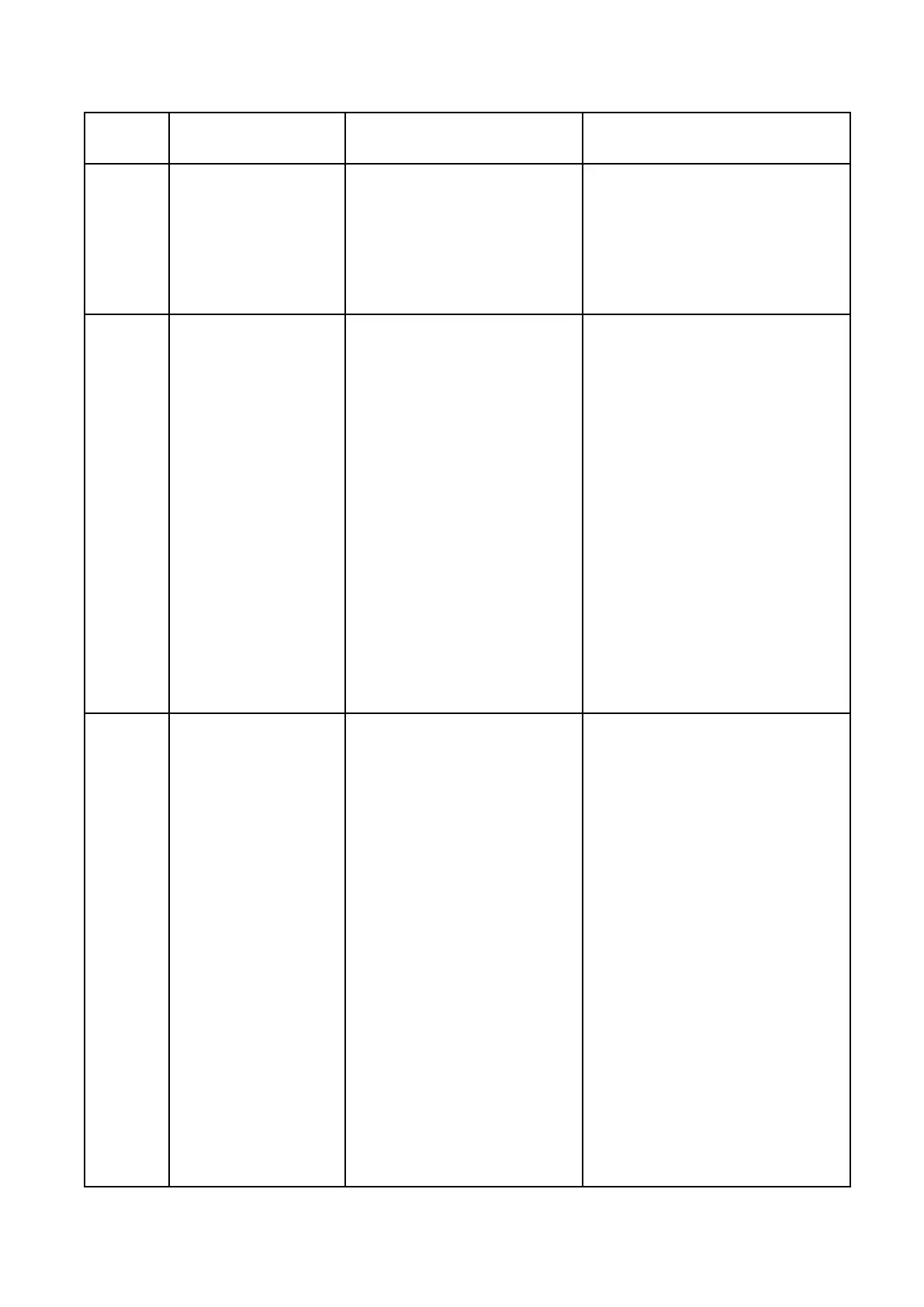

1. The load is too heavy

2. The acceleration and

deceleration times are too

short

3. The motor is driven below

the rated speed with a high

load

4. Incorrect setting in P1-00

(Motor Protection Function

Selection) when running a

special motor

5. The voltage determined

by the V/F is too high

6. d2-00 (Motor Rated

Current ) setting incorrect

7. The base frequency is set

too low

8. Use one drive to run

multiple motors

1. Check loading capacity

» Reduce the load

2. Confirm acceleration and

deceleration times

»Increase C1-00 to C1-03

parameter settings

3. »Reduce the load

» Increase the speed

» Either increase the motor

capacity or use a special-

purpose motor if the motor

needs to operate at low speeds

4. Set P1-00 to 2.

5. Adjust d1-02 to d1-09 settings

(V/F Characteristics)

Note: If d1-02 to d1-09 settings

are too low, load tolerance at

low speeds will be reduced

6.Confirm the motor rated

Loading...

Loading...