10

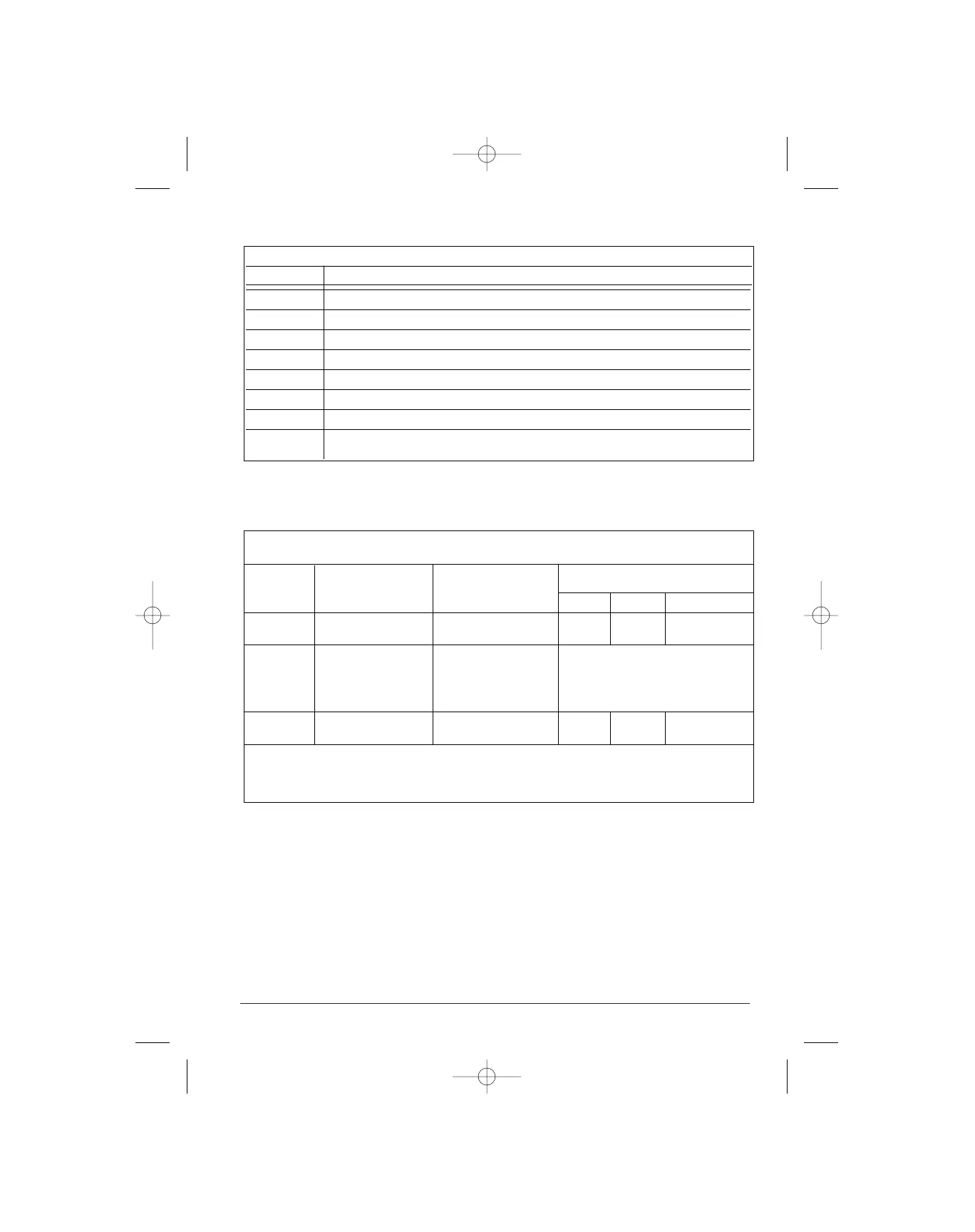

INSPECTOR’S REPORT

ITEM REMARKS (LIST DEFICIENCIES AND RECOMMENDED ACTION)

Inspector’s Date

Signature Inspected Approved by Date

Figure 13B — Recommended Inspector’s Report

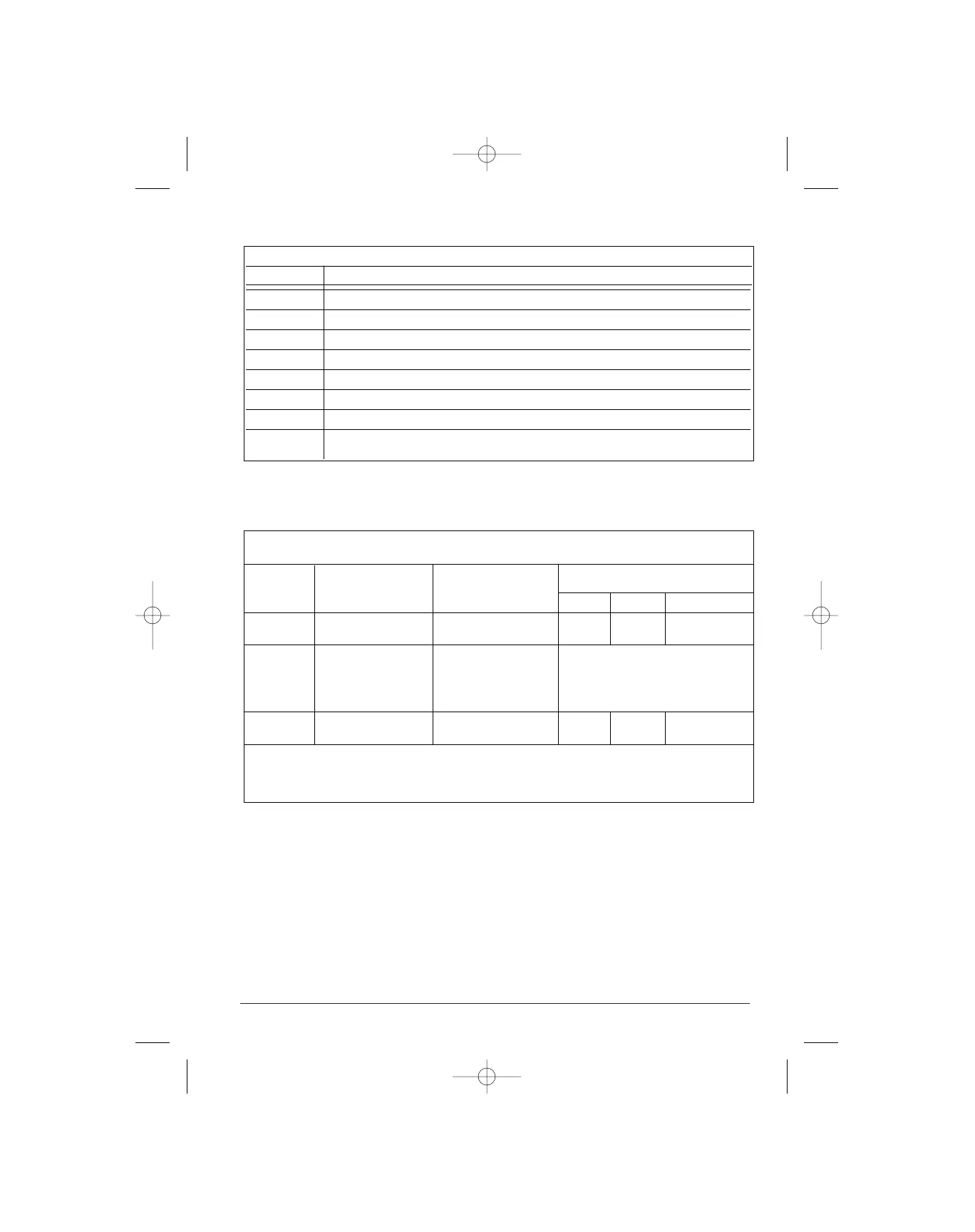

RECOMMENDED LUBRICATION SCHEDULE*

LITTLE MULE LEVER OPERATED CHAIN HOIST

FIGURE COMPONENT TYPE OF LUBRICANT TYPE OF SERVICE AND

NUMBERS FREQUENCY OF LUBRICATION

HEAVY NORMAL INFREQUENT

See Figures

Load Chain SAE 20-30 machine oil Daily Weekly Monthly

15 & 16

See Figures Load Pawl Shaft, Multi-purpose Lithium At periodic inspection

15 & 16 Pinion Shaft, Gear & base bearing grease (see Figure 13A)

Bearings, Pinion &

Gear Teeth

See Figures Bottom Block Shaft, SAE 20-30 machine oil

Monthly Yearly Yearly

15 & 16 Bearing & Hook Swivel

(*) This lubrication schedule is based on a hoist operating in normal environmental

conditions. Hoists operating in adverse atmospheres containing excessive heat,

corrosive fumes or vapors, abrasive dust, etc., should be lubricated more frequently.

CAUTION - DO NOT LUBRICATE BRAKE AREA OF HOIST.

Figure 14 — Recommended Lubrication Schedule

Loading...

Loading...