12 | P a g e

OPERATING INSTRUCTIONS

1. Turn on the power switch, the digital display will show amps, and the cooling fan will begin to

start turning.

2. Adjust knob of the desired welding current ranging from 30-140amps.

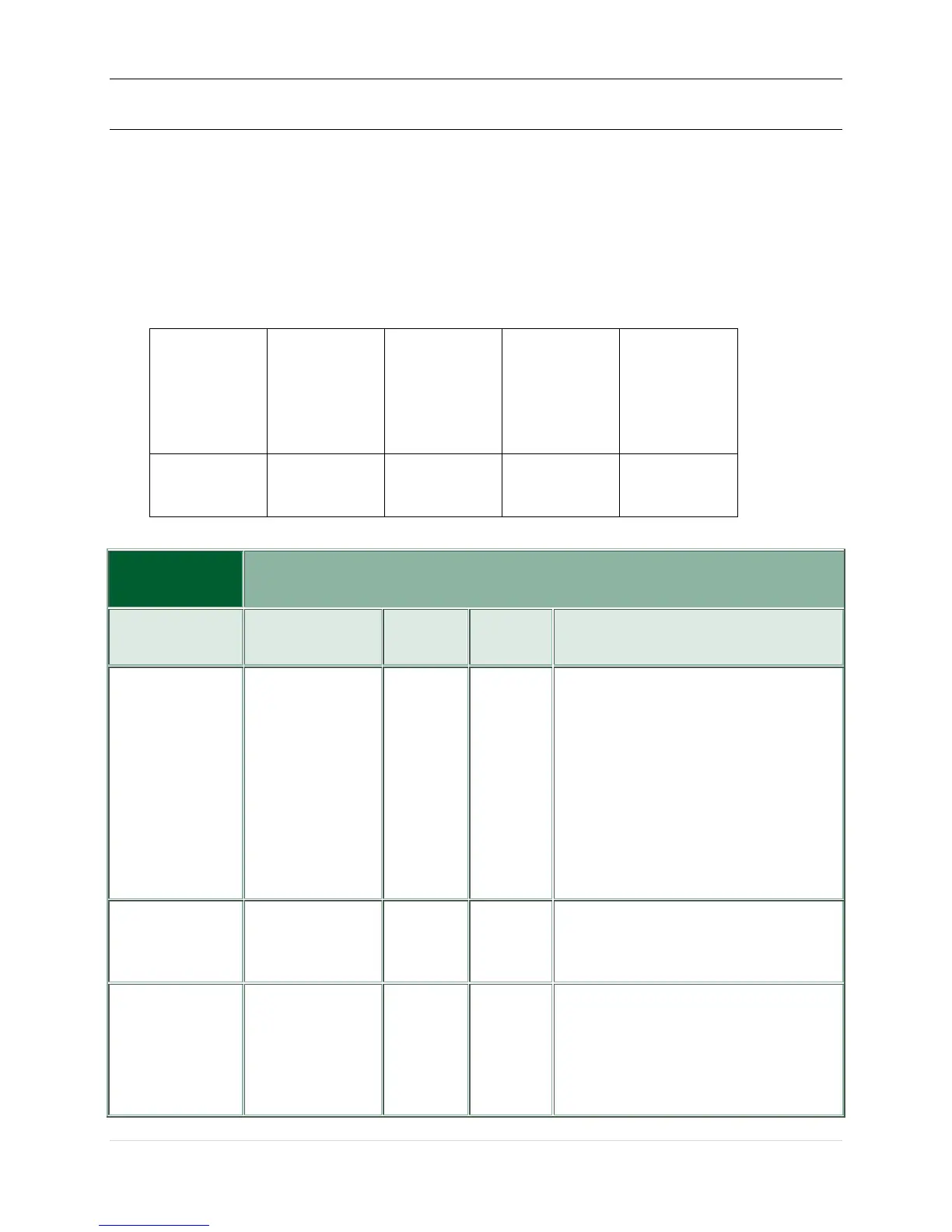

3. A general welding current chart is provided below:

Specification

of Diameter

in MM

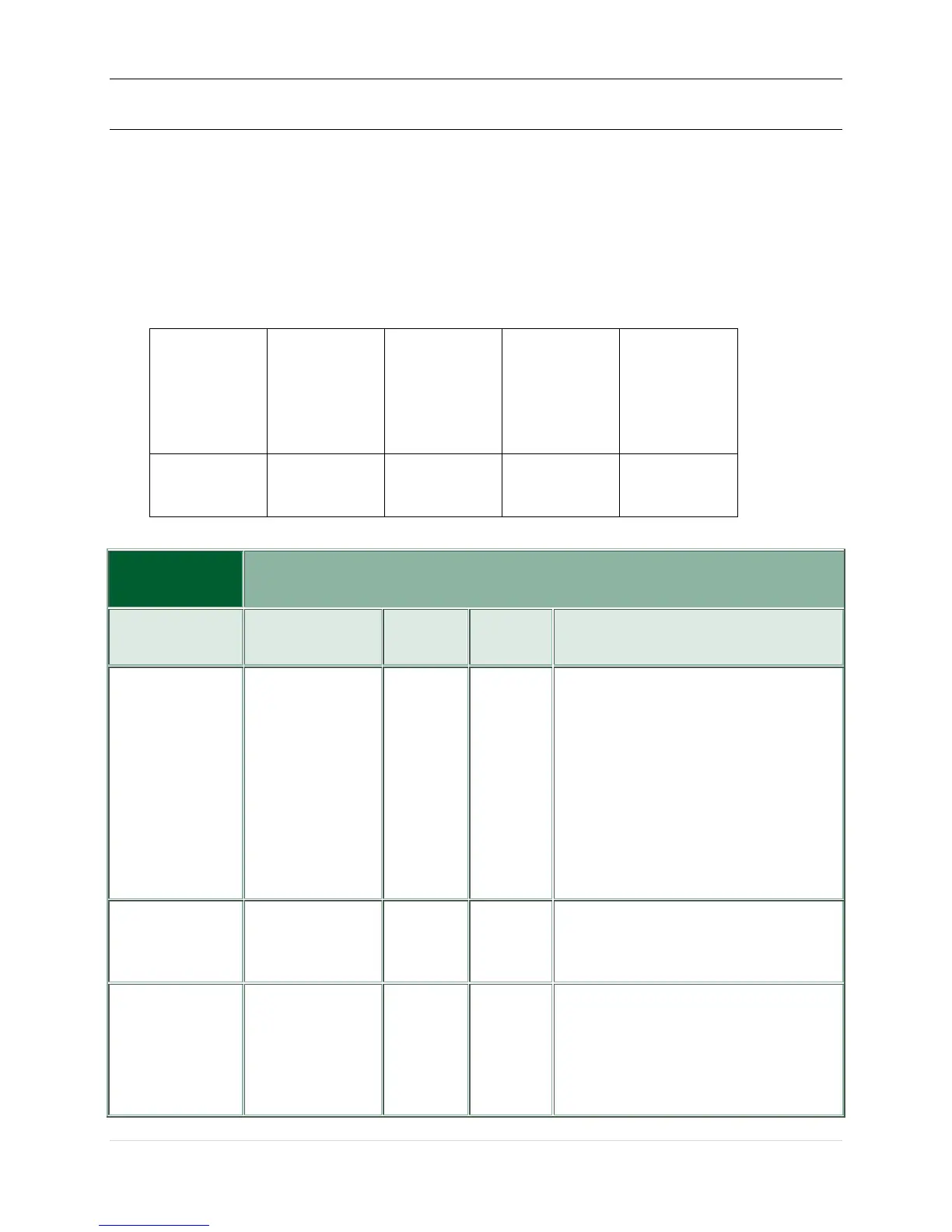

4. Here is a Stick Welding Classification Chart:

Covered Electrodes for SMAW of Carbon Steel per AWS A5.1

Arc-Welding Processes - SMAW

Characteristics, applications

A general purpose electrode for

joining of carbon steel.

Deep-penetrating forceful arc.

Thin slag. Us in all positions,

single and multiple pass, plate

and pipe, galvanized and alloy

steels. Ships, bridges, buildings,

piping, tanks, pressure-vessel

fittings.

Similar to E6010, but for use

with ac. Dcep gives reduced

penetration.

Dense slag that covers the bead,

low-penetrating arc. Use to

bridge joints with poor fitup.

Fillets have smooth convex

face. Runs well at amps higher

Loading...

Loading...