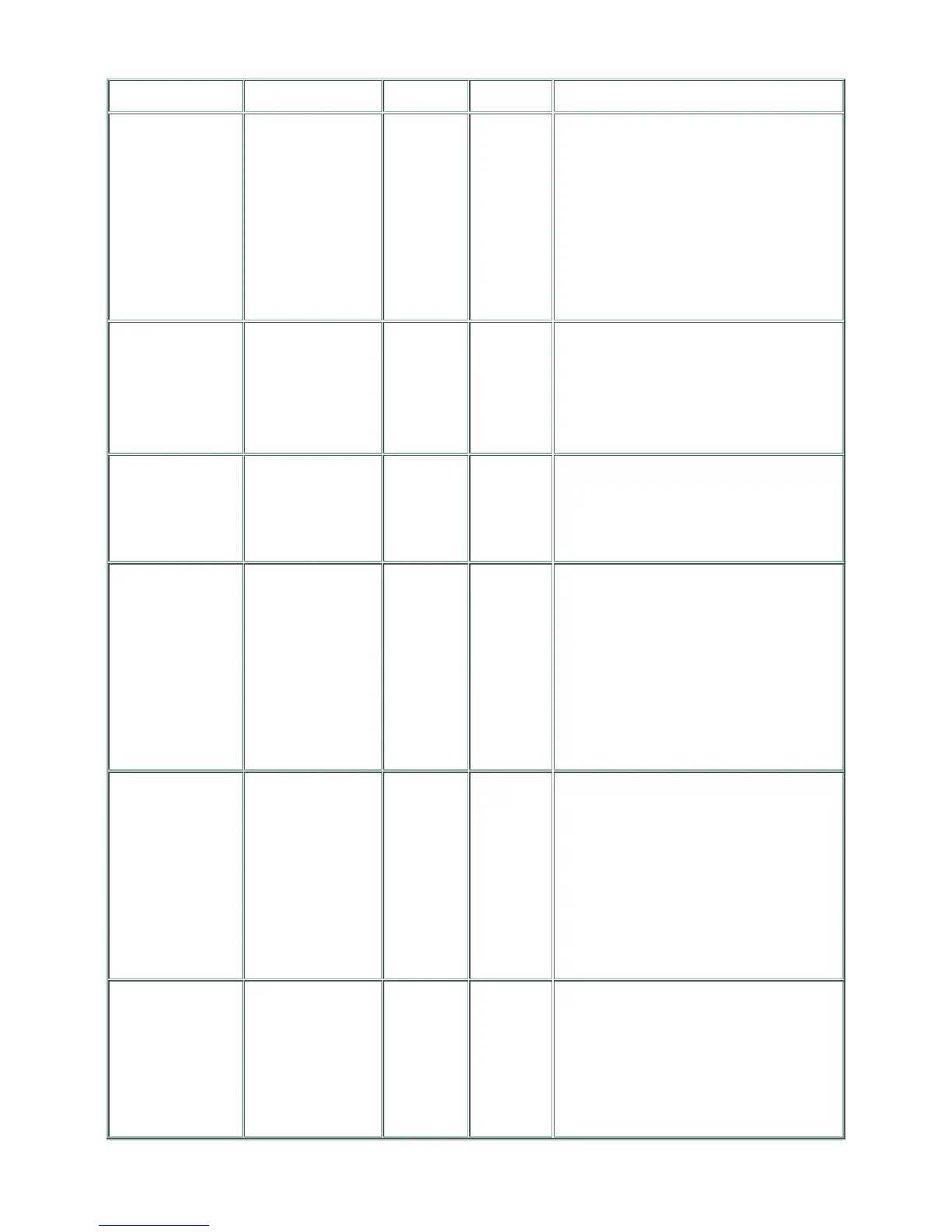

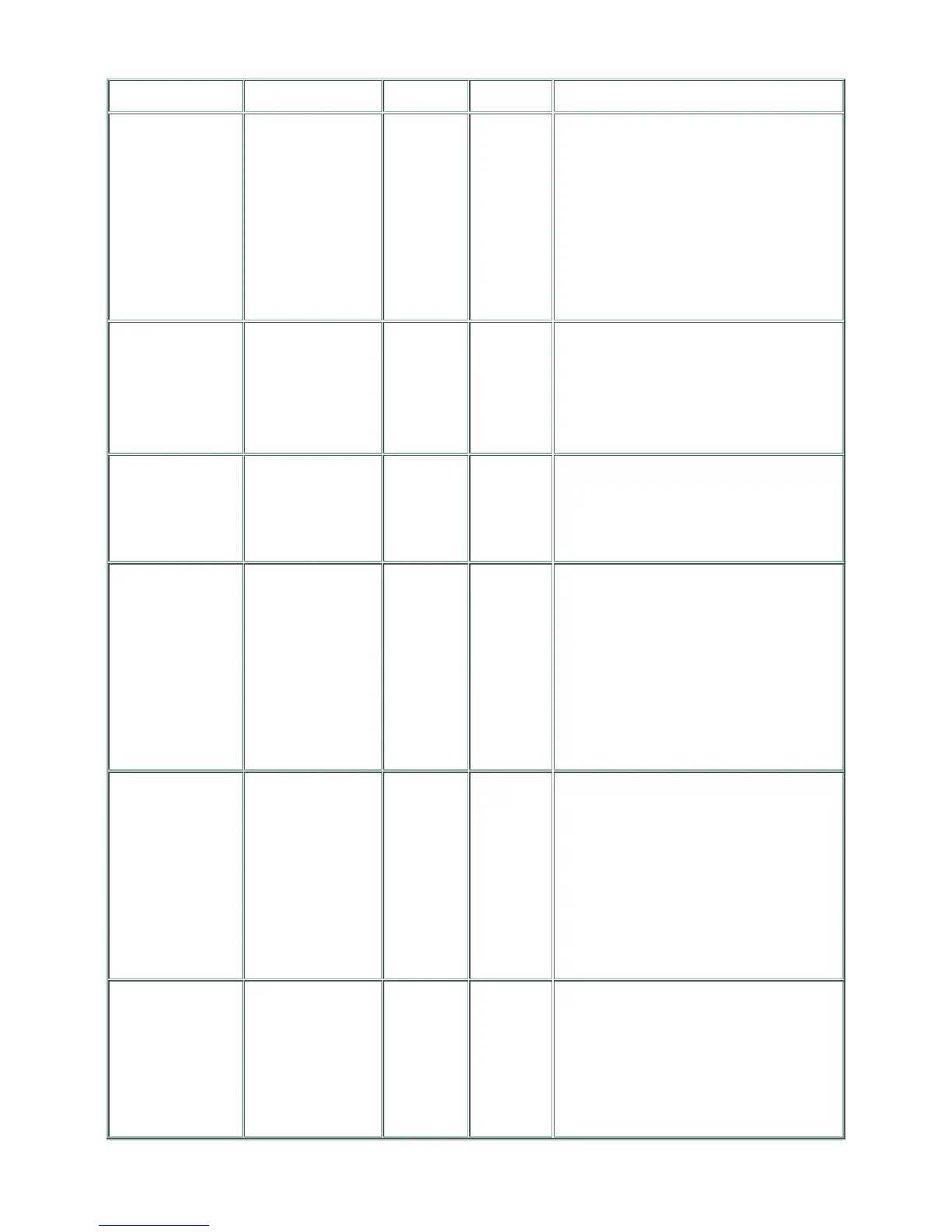

13 | P a g e

Similar to E6012; quieter arc,

smoother bead, cleaner weld

metal, fewer inclusions

Characteristics vary with

supplier. Run at lower current

than for E6012.

Use for single-pass,

high-current, high-speed

welding of groove welds in flat

position horizontal lap joints

and fillet welds in sheet metal.

High iron

oxide,

iron powder

For fillet of groove welds, flat

position, heavy slag, good

sidewall fusion. Use at high

amperages on thick plate.

Iron powder boosts deposition

rate and efficiency. Use at high

amperages on carbon and

low-alloy steels.

Low-penetrating arc, use to

bridge poor fitups. Smooth,

fine-rippled bead, convex

fillets.

E7018,

7018-1

7018R

7018-1R

7018H16, H8,

H4

Low-hydrogen

potassium,

iron powder

Iron-powder addition increases

deposition rate. Use on carbon,

high-carbon, and low-alloy

steels. Smooth arc, low spatter.

Flat and horizontal welds are

finely rippled. Convex. Other

types: E7018-1H16R,

E7018-1H8R, E7018-1H4R.

Yield strength, 53,000-72,000

lb/in. Ductility high, extra

impact strength and

compositional limits and limits

on moisture and hydrogen.

Similar to E7018-1H4R,

Loading...

Loading...