8

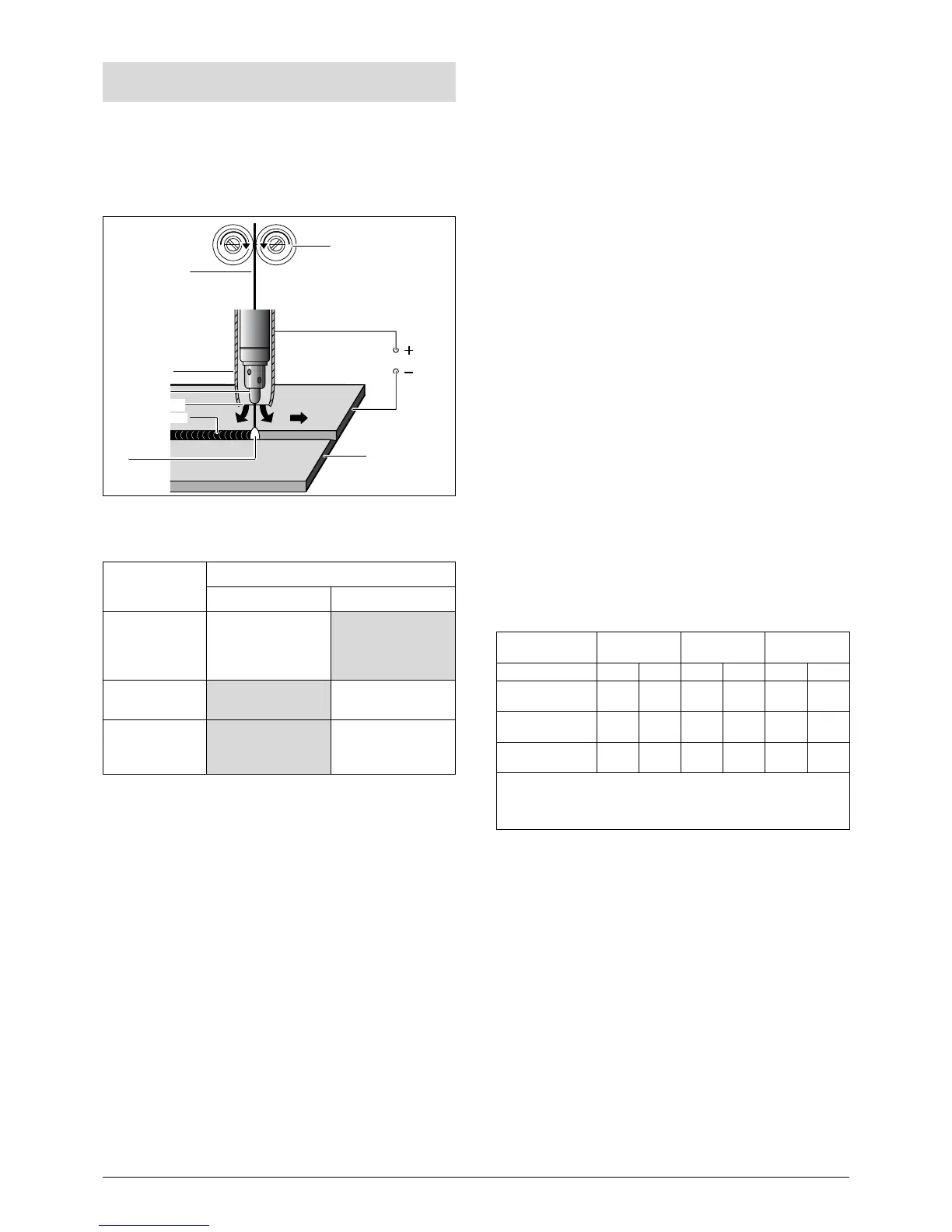

Principal of the MIG/MAG welding

The welding wire is fed from the wire coil to the contact tip due

to the wire-feeding rolls. The arc burns between the melting

wire electrode and the workpiece. The welding wire acts as

arc carrier and filler material. Shielding gas flows through the

gas nozzle and protects the arc against the atmospheregas.

At metal shielded gas welding both, inert and active gases are

used. The distinction is made between Metal Inert Gas (MIG)

and Metal Active Gas (MAG) welding.

Further possible classification is by the type of arc. This

means the external form of the arc, is proneness to short-

circuiting, and the way of transfer to the workpiece.

It is not possible to select the arc force to each individual

welding process. This is only limited possible for example at

the short circuiting arc.

Short-arc welding is possible with all shielded metal arc weld-

ing processes through selection of the suitable arc voltage

and the respective speed of the wire-feed.

Types of arc

Short circuit arc

This type of arc is specially suitable for thin materials and po-

sitional welding due to a relative cool welding pool welded

with very short arc, low arc voltage and low current. The ma

-

terial transfer takes place within the short circuit.

This cycle is repeated again and again so the short circuit and

the arcing period is constantly alternating.

)

The transition from the short circuit to spray arc de-

pends on the wire diameter and the gas mixture.

Transitional arc

With continuously increasing current, the limit range from

short arc to transition arc is achieved. The material transfer

takes place partly within the short circuit and partly out of it.

The transition arc is a critical current range, characterised by

intensive spattering. This range should be avoided, if possi

-

ble.

Long arc

Long arcs are typical at welding at the higher ampere range

under carbondioxid and gases with a high CO2 content. It is

not particularly suitable for positional welding. In this type of

arc large drops are formed which falls into the welding pool

mainly by force of gravity. Due to that short circuits occasion-

ally occur, which by the increase of the current at the moment

of the short circuiting lead to spattering when the arc is reignit

-

ed.

Spray arc

The spray arc is not suitable for positional welding, due to the

extremely liquid nature of the welding pool. The spraying arc

forms by welding at the higher range of ampere using inert

gas or mixtures with high argon content. The most typical

characteristic of the spray arc is the short circuit free transfer

of extremely fine droplets.

Working range at MAG welding

Principle of msg-soldering

The process of msg-soldering is very similar to the proc-ess

of msg-welding. Because of the lower temperature,the base

material is not fuzed but jointed by melting thesolder which

coates the materials.

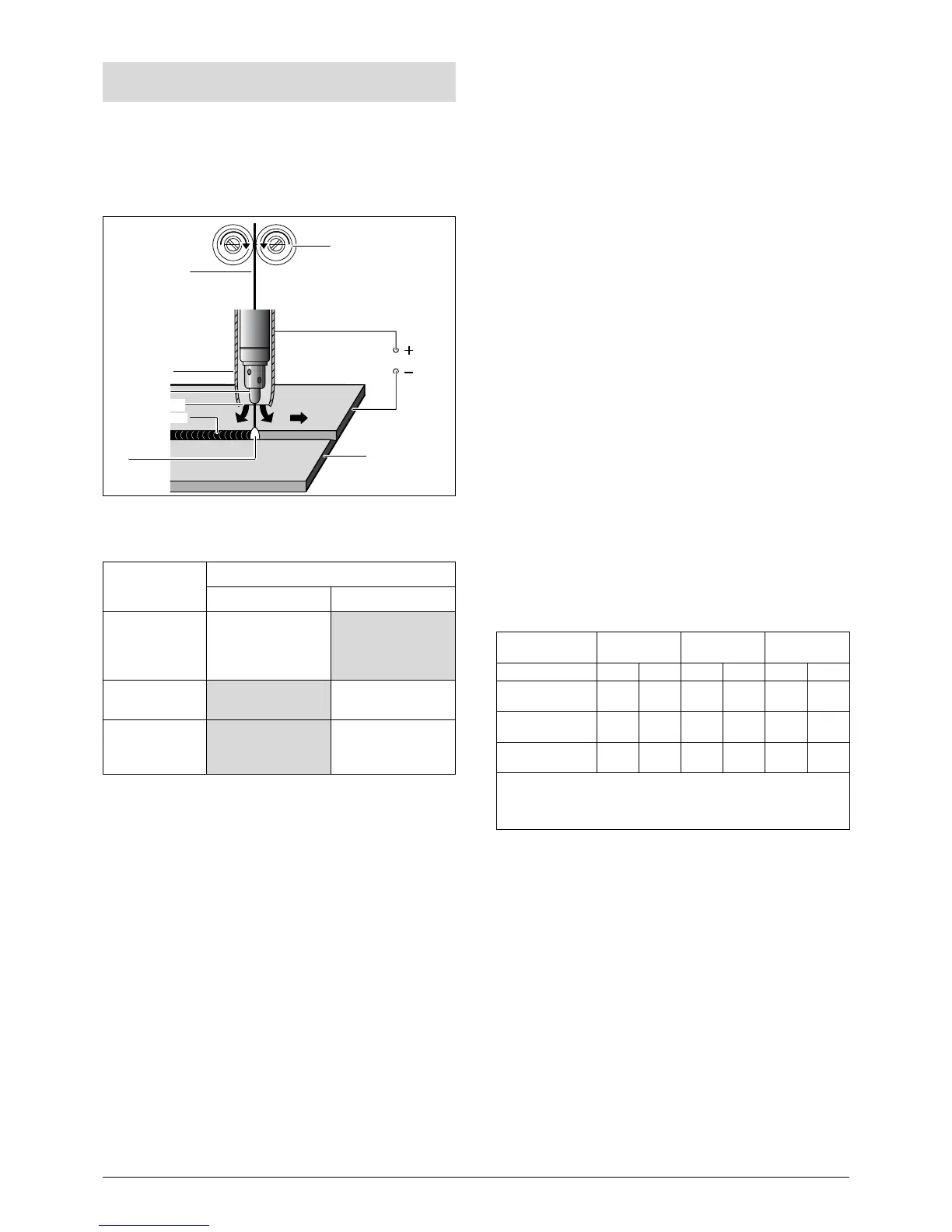

10 Basics of the MIG/MAG welding pro-

cess

Welding

Process

Shielding Gas

Inert Active

MIG Helium (He)

Argon (Ar)

Mixtures of

Ar/He

MAG-C Carbon dioxide

100 % CO

2

MAG-M Mixtures of

Ar/CO

2

Ar/O

2

Loading...

Loading...