CDA3000 Operation Manual

2-7

2 Mechanical installation

1

2

3

4

5

A

DE

EN

FR

IT

ES

FR

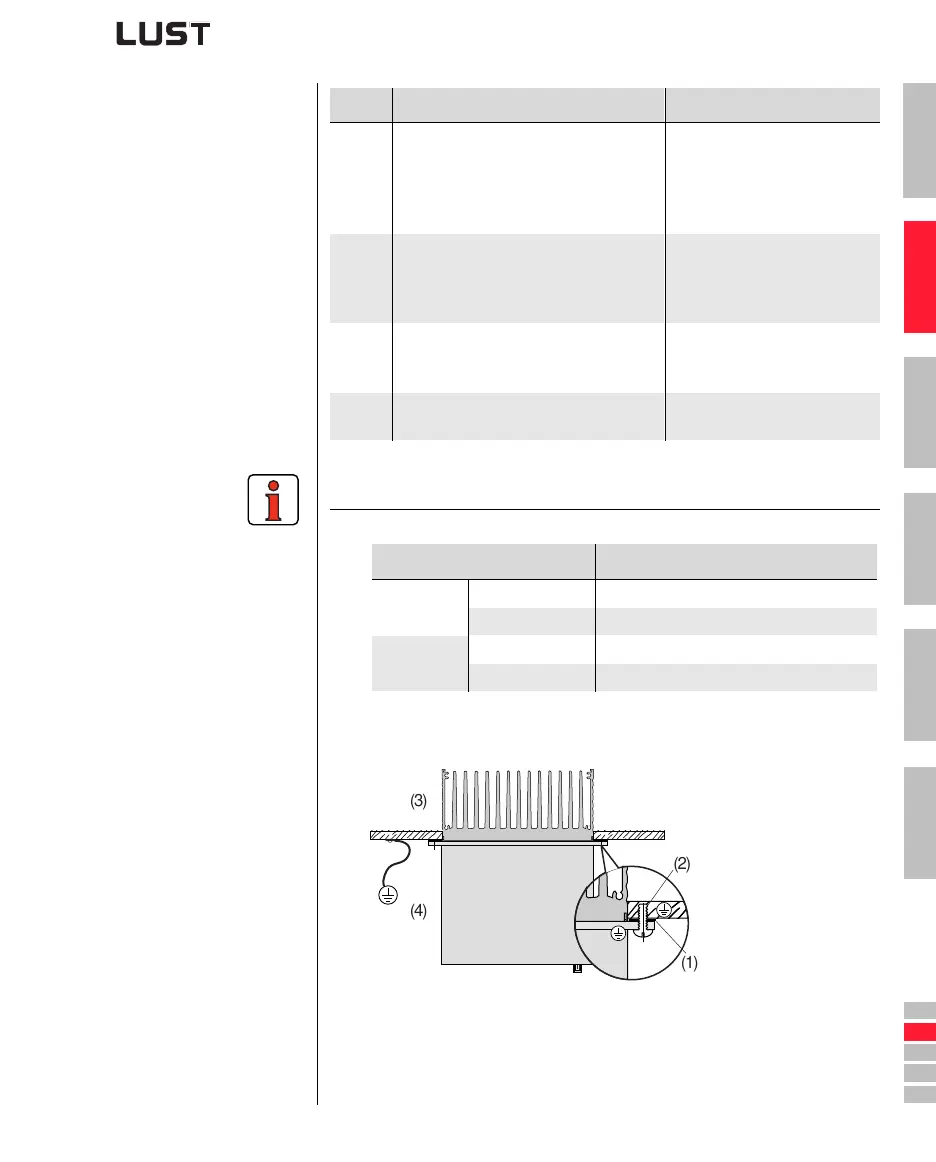

2.5 Push-through

heat sink (Dx.x)

Step Action Comment

1

Mark out the positions of the tapped

holes and the breakthrough on the

backing plate.

Cut a tap for each fixing screw in the

backing plate.

Dimensional drawings/hole

spacing - see Table 2.6.

The tapping area will provide

you with good, full-area contact.

2

Mount the inverter module vertically on

the backing plate. Tighten all screws to

the same tightness.

Pay attention to the mounting

clearances! The mounting seal

must contact flush on the sur-

face.

3

Mount the other components, such as the

mains filter, line choke etc., on the

backing plate.

Mains filter max. 20 cm below

the inverter module

4

Continue with the electrical installation in

section 3.

Note the following points:

• Distribution of power loss:

• The all-round mounting collar must be fitted with a seal. The seal

must fit flush on the surface and must not be damaged:

(1) Seal

(2) Tapped hole for

EMC contact

(3) Outside

(4) Inside

• The backing plate must be well grounded.

• The best result for effective EMC installation is attained with a chro-

mated or galvanized backing plate. If backing plates are varnished,

the coating must be removed in the area of the contact surface!

BG3 BG4 BG5 BG6

Power loss

Outside (3) 70% 75% 80% 85%

Inside (4) 30% 25% 20% 15%

Protection

Heat sink side (3) IP54 IP54 IP54 IP20

Machine side (4) IP20 IP20 IP20 IP20

(1)

(4)

(3)

(2)

Loading...

Loading...