MSP4 / MSP5 / MSP6

P. 5 / 7EM-4854 Rev.8

ADJUSTMENT PROCEDURE

■ ADJUSTMENT PROCEDURE

A) Zero and Span

• Apply 0% [100%] input. Turn the zero adjustment for the

fully extended position (valve stem fully retracted) or ad-

just the connecting section of the valve stem.

Adjust the

output stem, referring to Table 4, to provide an

adequate sealing spring if necessary.

• W

ith 100% [0%] input, turn the span adjustment until the

MSP reaches required fully retracted position (valve stem

fully extended).

For

three-way valves, the sealing pressure can be adjusted

to be applied in the direction where the output stem is

fully retracted*

2

. Adjustment procedure is the same for

zero.

• W

ith 0% [100%] input again, check that the MSP is at

the fully extended position. If the position is shifted, go

through the above procedure again.

Remark 1: There is only minimal effect of span adjustment

to zero point, thus the stem position shifts very little at the

extended side when the span potentiometer is turned.

Remark 2: With the stroke narrower, hunting (the motor

repeats changing direction) can happen more often. Adjust

Deadband in such cases.

*2. The sealing spring for the MSP4 is provided only for the

direction where the output stem is retracted.

Table 2. Switching Actions

ACTION SW1-3 EXPLANATIONS*

1

Direct ON Output stem is retracted with an

input decrease.

(Valve stem extended)

Reverse OFF Output stem is extended with an

input decrease.

(Valve stem retracted)

Table 3. Operations at Abnormally Low Input

OPERATION SW1-1

SW1-2

Stop *

1

ON

Extend OFF OFF

Retract ON OFF

*1.

Whatever setting for SW1-1 is disregarded for Stop mode.

Open the cover and adjust ZERO, SPAN, DZ (deadband),

DLY (re-starting timer) potentiometers and the direct/re-

verse SW on the control PCB as shown in Figure 3.

Other adjustments which are paint locked are for factory

use only and should be changed only by qualified M-System

personnel. M-System is not liable for any malfunction or

inconvenience caused by unauthorized change of them by

the user.

■ DIRECT/REVERSE ACTION

The actuator action is factory set to “Reverse” (the output

stem is retracted, with an input signal increase.), and the

operation at abnormality to “Extend.” For changing the set-

ting, use the DIP SW on the control PCB. Refer to Tables

2 and 3.

Remark 1: SW1-4 is not used.

Remark 2: With the direct action, the position output is 5

– 1V DC proportional to the input 0 – 100%.

■ GENERAL

After installing the valve and actuator, go to adjustments in

order of zero, span, seal-spring and sensitivity (deadband).

If optional limit switches are provided, adjust them at the

last.

The following explanation applies to reverse action For di-

rect action, read the value in the brackets [ ].

Remark: Applying an over-torque to the adjustments may

destroy stoppers or other sections of them. Use a small-

sized screwdriver and be sure to stop turning as soon as

they hit the stoppers.

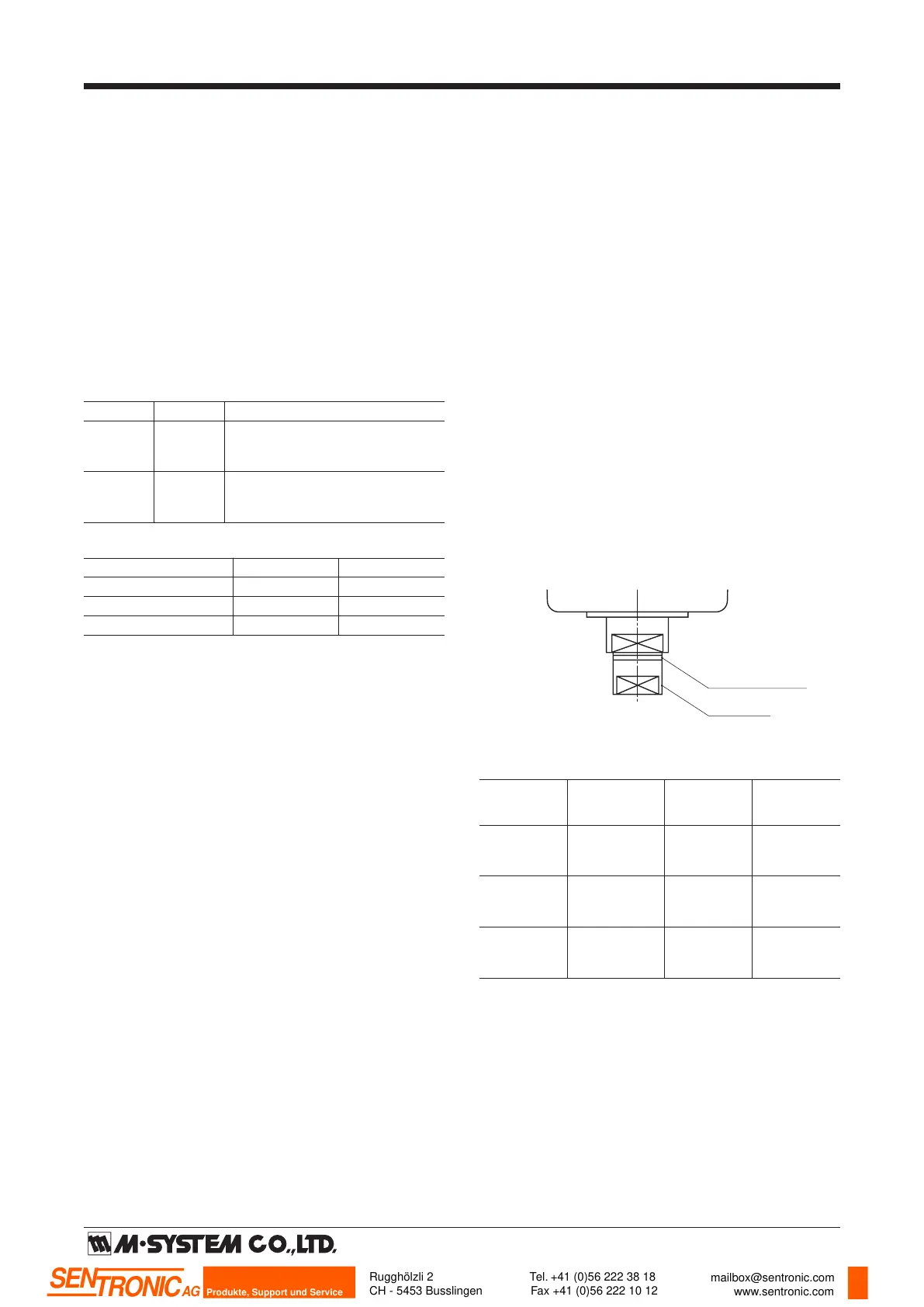

Seal-Spring Division

Output Stem

Figure 8. Seal-Spring

Table 4. Spring Contraction

SPRING SEALING CONTACT*

MODEL CONTRACTION PRESSURE PRESSURE

(mm) (N / lbs) (N / lbs)

MSP4-x3 0.5 147 / 33 98 / 22

MSP4-x4 1.0 300 / 67 250 / 56

MSP4-x7 1.0 686 / 154 294 / 66

MSP5-x3 0.5 150 / 34 110 / 25

MSP5-x4 1.0 294 / 66 216 / 49

MSP5-x7 1.0 686 / 154 294 / 66

MSP6-x3 1.0 588 / 132 441 / 99

MSP6-x4 1.0 1170 / 263 882 / 198

MSP6-x6 1.5 2350 / 529 1170 / 263

*The minimum pressure required to contract the spring.

Remark: Graduations by 1 millimeter increments are

marked on the stem. For example, with MSP4-x7, the seal-

ing pressure reaches approx. 490 N at 0.5 mm, 686 N at 1

mm.

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

Loading...

Loading...