37

MAINTENANCE SECTION

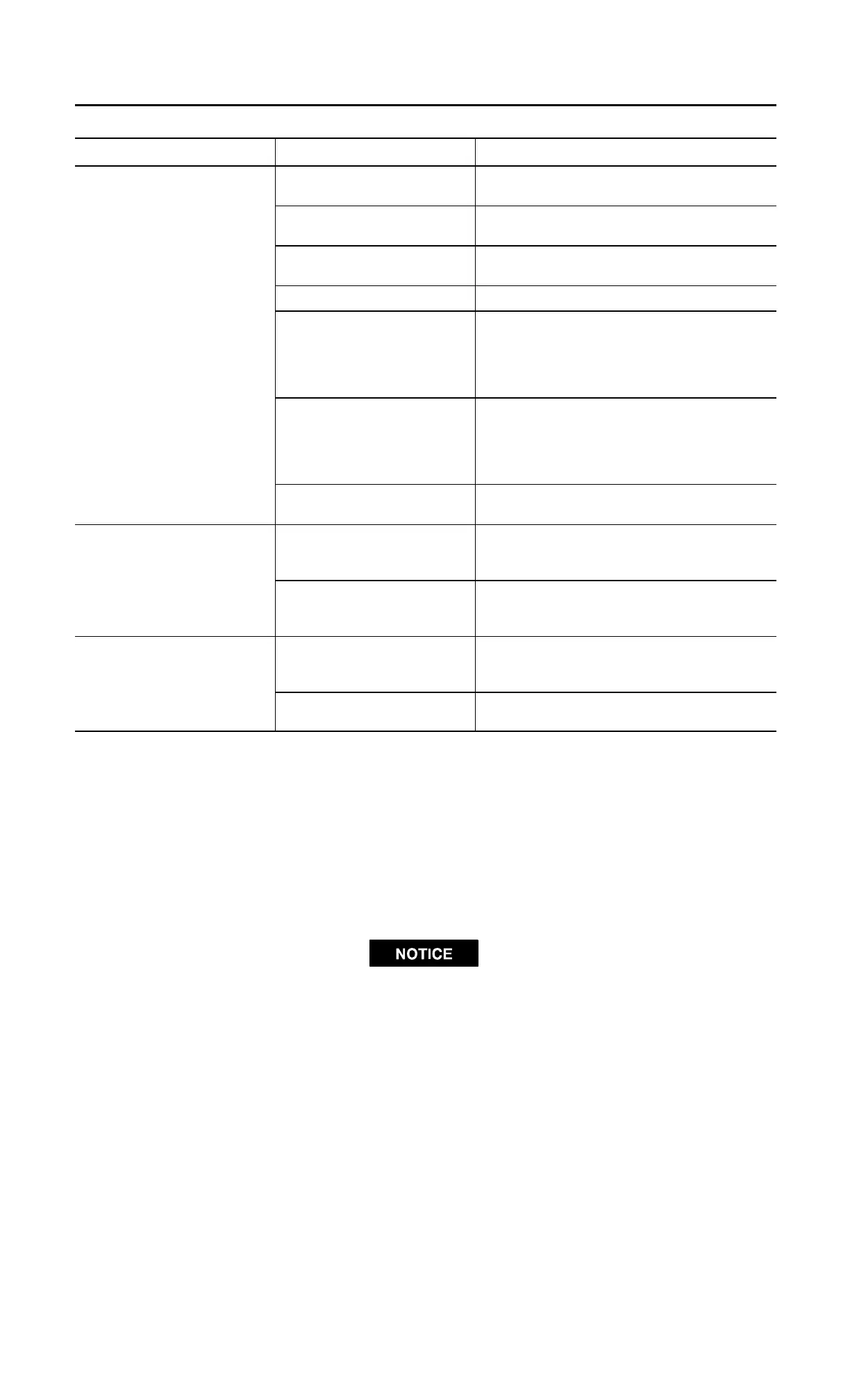

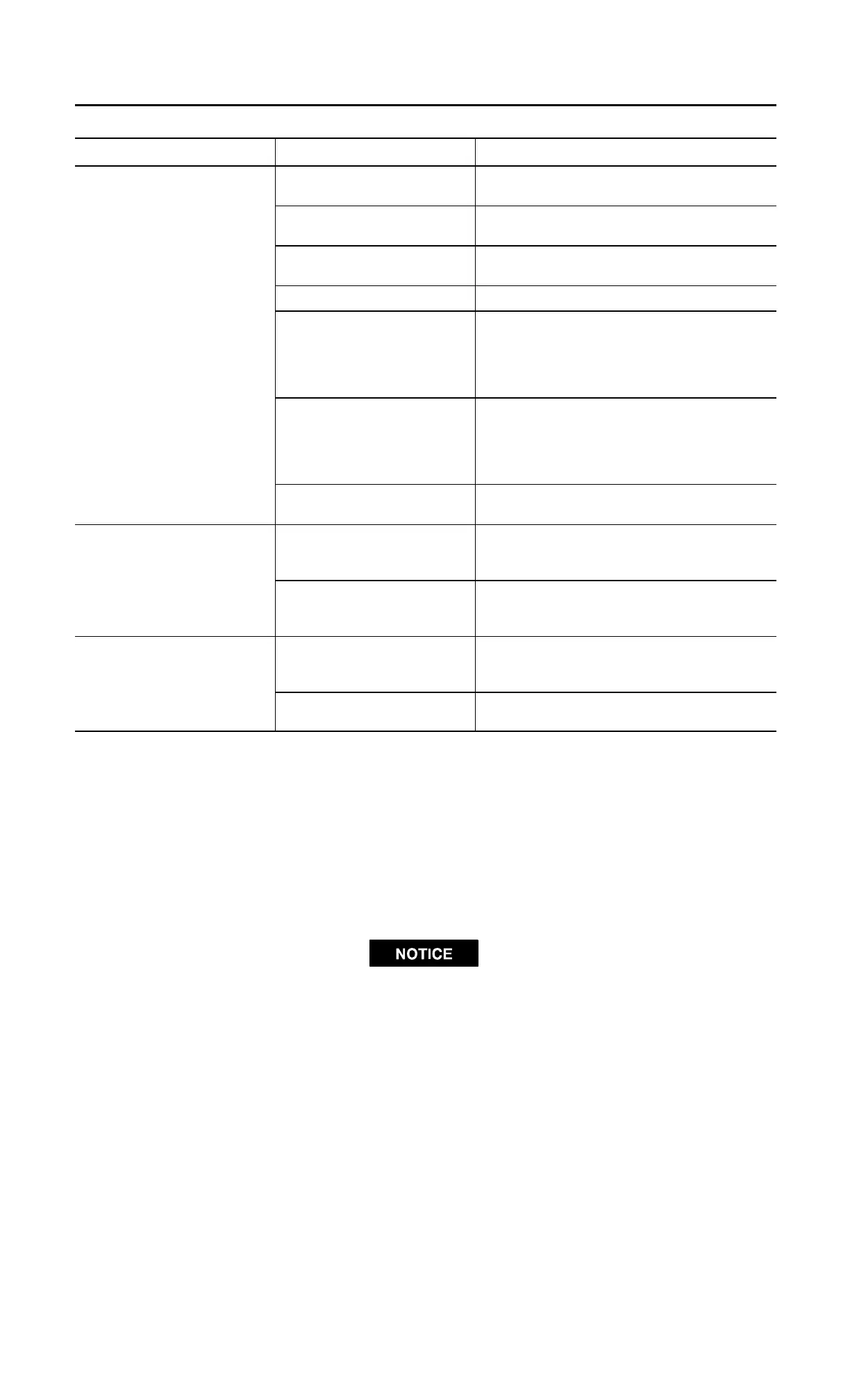

TROUBLESHOOTING GUIDE

Trouble Probable Cause Solution

Low power Dry Motor Daily, inject 3 cc of Mac Tools Pneumatic Oil into

the inlet and run the tool to lubricate the motor.

Inadequate air supply Install proper air supply and connection. Refer to

Dwg. TPD905–1 and Dwg. TPA1814 on Page 3.

Dirty Inlet bushing Screen Using a clean, suitable, cleaning solution in a well

ventilated area, clean the Inlet Bushing Screen.

Worn or broken Vanes Replace a complete set of Vanes

Worn or broken Cylinder and/or

scored End Plates

Examine Cylinder. Check outside and ends for

wear or damage and inside for scored or wavy

bore.

Replace Cylinder if any of these conditions exist.

Replace End Plates if they are scored.

Dirty motor parts. Disassemble the Tool and clean in a clean, suit-

able, cleaning solution in a well ventilated area.

Assemble the Tool and inject 3 cc of the

recommended oil into Inlet and run Tool to

lubricate internal parts.

Damaged Reverse Valve Replace Reverse Valve. Refer to Installation of

Reverse Valve.

Motor will not run Incorrect assembly of motor Disassemble motor and replace worn or broken

parts and reassemble. Refer to Assembly of the

Motor.

Insufficient lubricant in impact

mechanism.

Lubricate impact mechanism through Hammer

Case Grease Fitting using the recommended

grease.

Tool will not impact Broken or worn impact mecha-

nism parts

Remove Hammer Case Assembly and examine

impact mechanism parts. Replace any worn or

broken parts.

Impact mechanism not

assembled correctly.

Refer to Assembly of Impact Mechanism.

SAVE THESE INSTRUCTIONS. DO NOT DESTROY.

Loading...

Loading...