OM-154 500 Page 2

SECTION 2 – INSTALLATION

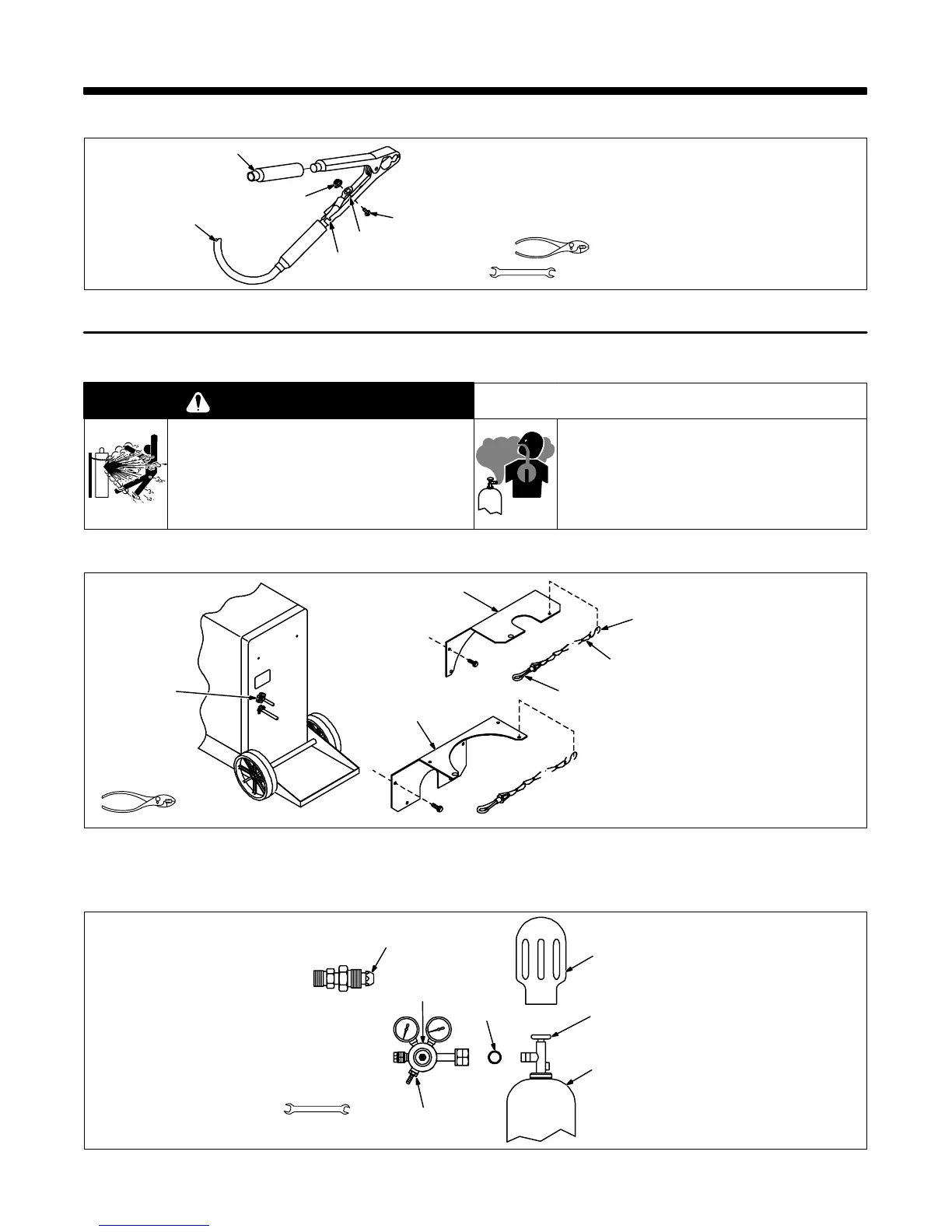

2-1. Installing Work Clamp

1 Insulator

2 Bolt

3 Smaller Hole

4 Work Clamp Tabs

Bend tabs around work cable.

5 Work Cable From Unit

6 Nut

Ref. ST-025 190-C

Tools Needed:

3/8, 7/16 in

1

2

3

4

5

6

Figure 2-1. Installing Work Clamp

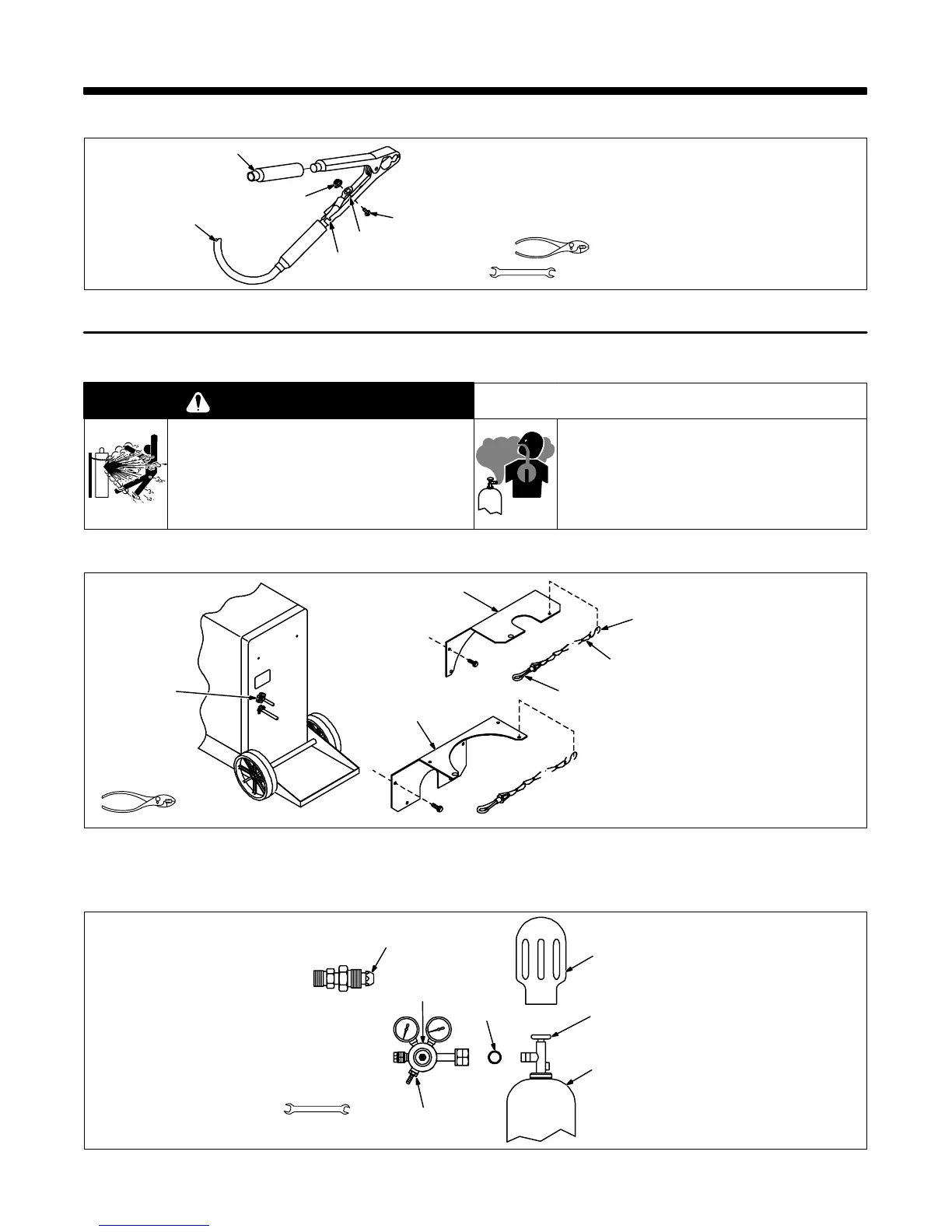

2-2. Installing Gas Supply

WARNING

CYLINDERS can explode if damaged.

• Keep cylinders away from welding and other

electrical circuits.

• Never touch cylinder with welding electrode.

• Always secure cylinder to running gear, wall, or

other stationary support.

BUILDUP OF SHIELDING GAS can harm

health or kill.

• Shut off shielding gas supply when not in use.

warn4.1 9/91

A . Installing Safety Chain

1 Cylinder Bracket As Shipped

2 S-Hook

Crimp between small hole in

bracket and chain.

3 Chain

4 Snap

Crimp onto open end of chain.

5 Cylinder Bracket For Large

Gas Cylinder

6 Gas Fitting

ST-160 791

1

2

3

Tools Needed:

4

5

6

Figure 2-2. Installing Safety Chain

B . Installing Regulator/Flow Gauge

Obtain gas cylinder and chain to

running gear, wall, or other station-

ary support.

1 Cap

2 Cylinder Valve

Remove cap, stand to side of valve,

and open valve slightly. Gas flow

blows dust and dirt from valve.

Close valve.

3 Cylinder (CO

2

shown)

4CO

2

O-Ring

ssb3.1* 12/92 – ST-154 583 / ST-154 623 / Ref. ST- 800 746

Tools Needed:

1-1/8, 5/8 in

5

6

2

3

4

1

5 Regulator/Flow Gauge

Install so face is vertical.

6 Gas Hose Connection

Install gas hose between flow

Gauge and welding power source.

Flow rate is set to 20 cfh (cubic feet

per hour).

7 Adapter

Install adapter between regulator/

flow gauge and cylinder when using

argon or mixed shielding gas.

7

Figure 2-3. Installing Supplied Regulator/Flow Gauge

Loading...

Loading...