1. Park the combine on a level surface, and ensure the feeder house is level.

2. Ensure the top of the oat module is level with the combine axle and the combine

res are inated equally.

3. Adjust the header so the cuerbar is 150–254 mm (6–10 in.) o the ground.

4. Set the header angle hydraulic cylinder to between B and C on indicator (A).

5. Adjust the reel fore-a to the middle posion (5 or 6 on the reel arm decal).

6. Lower the reel completely, shut down the combine, and remove the key from the

combine ignion.

7. Place wing lock spring handles (B) in the locked (upper) posion.

8. Place both le and right header oat locks (C) in the unlocked (lowered) posion.

9. Set the stabilizer/transport wheels (if equipped) to the storage posion.

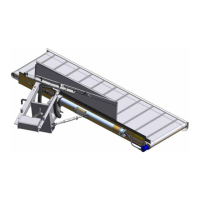

Step 1: Preadjustments

Complete before adjusng oat or wing balance.

IMPORTANT:

Read your operator’s manual and complete all the setup tasks before seng the

header oat.

Figure 4: Torque Wrench Storage Locaon

Figure 3: Float Unlocked – Right Side Shown

Figure 1: Header Angle Hydraulic Cylinder

Ensure your machine operates at top eciency by using only clean uids and lubricants. Use clean containers to handle all uids and lubricants. Store uids and

lubricants in an area protected from dust, moisture, and other contaminants.

Break-In Inspecons

To help avoid major component service or replacement, perform break-in inspecons on your machine during the rst 50 hours of operaon. Refer to your operator’s

manual for complete break-in inspecon and adjustment procedures.

Figure 2: Wing Lock Spring Handle in Locked Posion

Step 2: Retrieving Torque Wrench from Storage

1. Remove special torque wrench (A) from its storage posion at the right side of the

oat module frame. Pull in the direcon shown to disengage the wrench from

its hook.

Follow these ve steps to set the header oat and wing balance:

Inspecon Instance Item

First 5 Minutes Check hydraulic oil level in reservoir (check aer rst run-up and aer the hydraulic hoses have lled with oil).

5 Hours

Check for loose hardware and ghten to required torque.

Check knife drive belts tension (check periodically for the rst 50 hours).

10 Hours

Check auger drive chain tension.

Check knife drive box mounng bolts.

50 Hours

Change oat module gearbox oil.

Change oat module hydraulic oil lter.

Change knife drive box lubricant.

Check gearbox chain tension.

Check deck height adjustment.

Ongoing Maintenance Intervals

Refer to the operator’s manual for a comprehensive maintenance schedule and record. Log hours of operaon, use the maintenance record, and keep copies of your

maintenance records. Following the maintenance schedule will increase your machine’s life.

SETTING HEADER FLOAT AND WING BALANCE

Recommended Fluids and Lubricants

Lubricant Specicaon Descripon Use Capacies

Grease SAE mul-purpose

High temperature extreme pressure (EP)

performance grease with 1% max

Molybdenum Disulphide (NLGI Grade 2)

lithium base

As required unless

otherwise specied

—

High temperature extreme pressure (EP)

performance grease with 10% max

Molybdenum Disulphide (NLGI Grade 2)

lithium base

Driveline slip-joints —

Gear Lubricant SAE 85W-140 API service class GL-5

Knife drive box 2.2 liters (2.3 quarts)

Main drive gearbox 2.5 liters (2.6 quarts)

Hydraulic Oil

Single grade transmission/hydraulic uid (THF)

Recommended viscosity:

60.1 cSt @ 40° C (104° F)

9.5 cSt @ 100° C (212° F)

Recommended brands:

Petro-Canada Duratran

John Deere Hy-Gard J20C

Case Hy-Tran Ultracon

AGCO Power Fluid 821 XL

Lubricant trans / hydraulic oil

Header drive systems

reservoir

85 liters (22.5 US gallons)

Subject to change without noce

Loading...

Loading...