Page 4 of 20

Maintenance Procedures

Ensure that the fluid supply to the meter is dis-

connected, and the line pressure is released be-

fore disassembly, with the exception for repair or

maintenance to the LC Display or PCB where

there is no necessity to isolate the meter from flow.

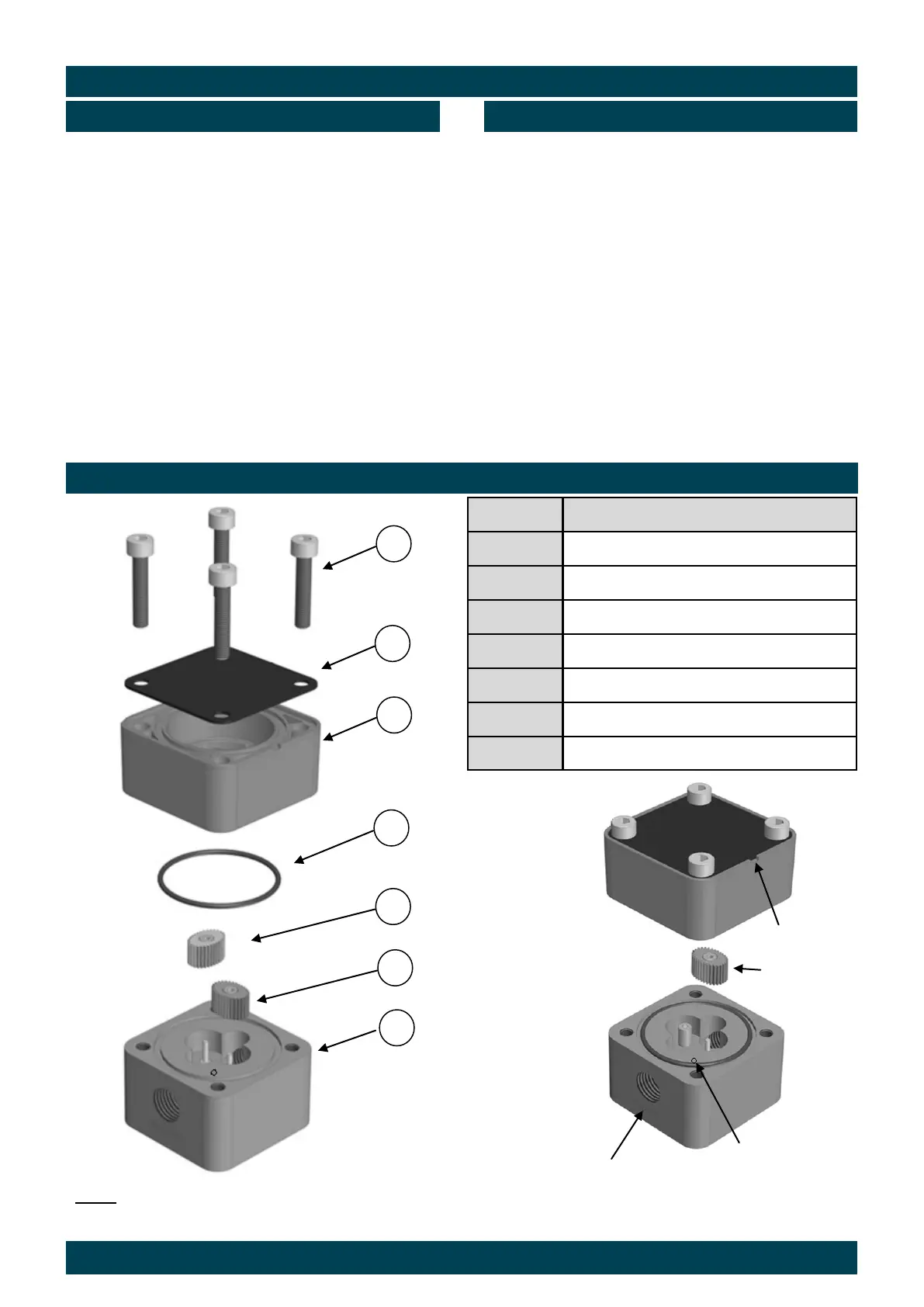

Refer to the below exploded parts diagram.

1. Loosen and remove 4 Phillips head or cap head

screws (Item 7).

2. Remove the meter cap (Item 5) and O-Ring (Item

4).

3. Remove the rotors (Item 2 & 3), note the position/

orientation of the rotor with the magnet(s) or grub

screws

4. Clean and Inspect all components, replace as

necessary, see page 12 & 13 for spare parts

listing.

1. Place the rotors (Item 2 & 3) on the shafts inside

the body at 90° to each other in the same way as

it was originally factory fitted. Rotate the rotors

by hand to ensure correct engagement.

2. Fit the O-Ring (Item 4) into the O-Ring groove in

the meter body (Item 1).

3. Fit the top cap assembly (Item 5), fit the legend

plate (Item 6) into correct orientation. Ensure all

the alignment marks are lined up with the mark

on the body.

4. Fit and tighten the 4 bolts/screws (1-3-2-4, Item 7

to the required torque. (See page 11 for details)

5. Check meter function using low air pressure.

Restore the fluid & reconnect the wiring as

detailed on pages 6-10.

Disassembly Reassembly

Item No Part Description

1 Meter Body

2 Active Rotor

3 Neutral Rotor

4 O-Ring

5 Meter Cap

6 Legend Plate

7 Meter Cap Screws

7

6

5

4

3

2

1

Exploded Diagram - Type M,F,S,CR

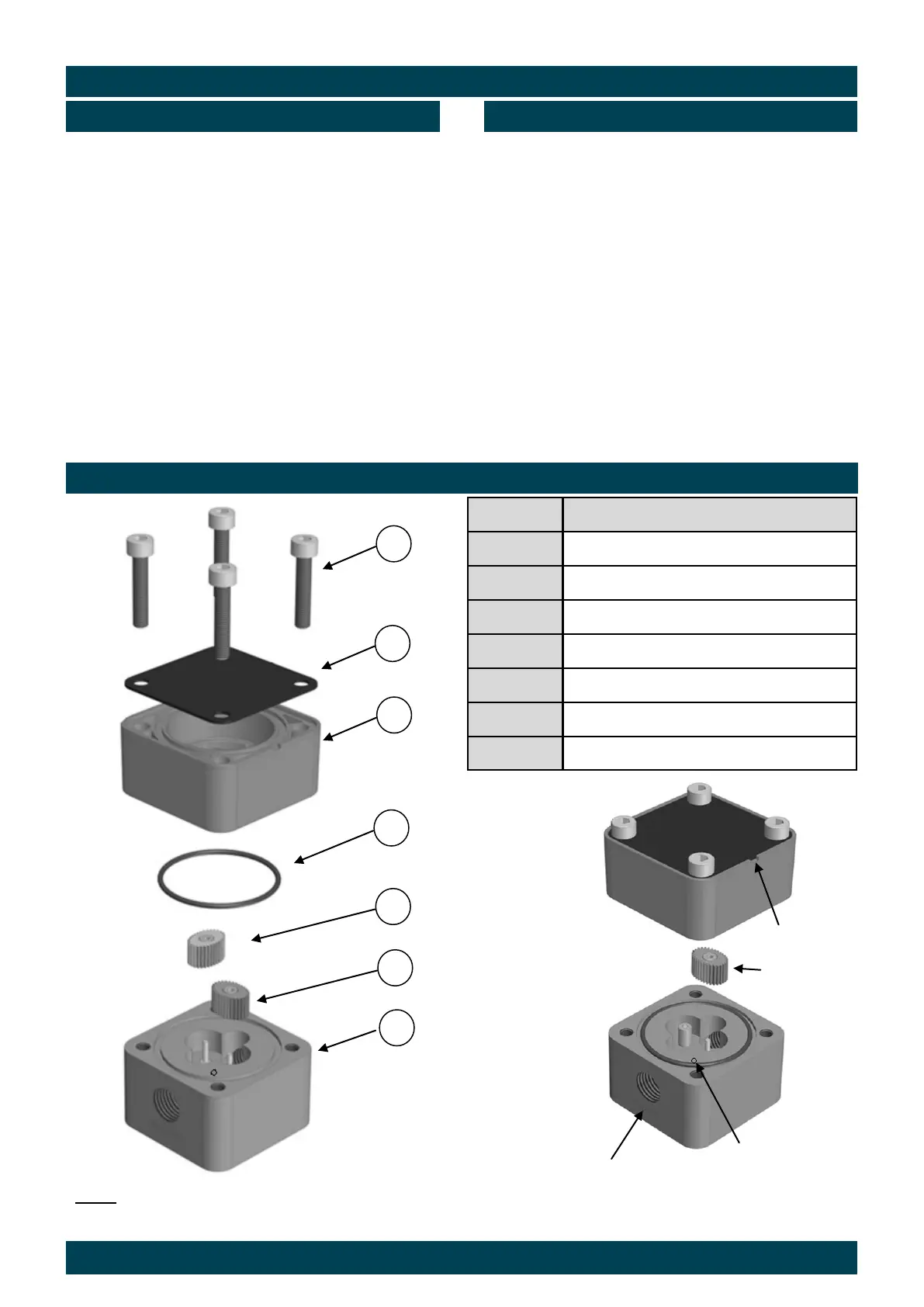

Cap Notch

Active Rotor

Port Inscription

Alignment Dimple

The Active Rotor, Alignment Dimple and Cap Notch must be aligned when assembling the flow-

meter. The ‘CR’ Range has a notch in the body not an alignment dimple. Magnet hole/grub screw

side must be facing the meter body.

Loading...

Loading...