Page 11 of 20

Troubleshooting Guide

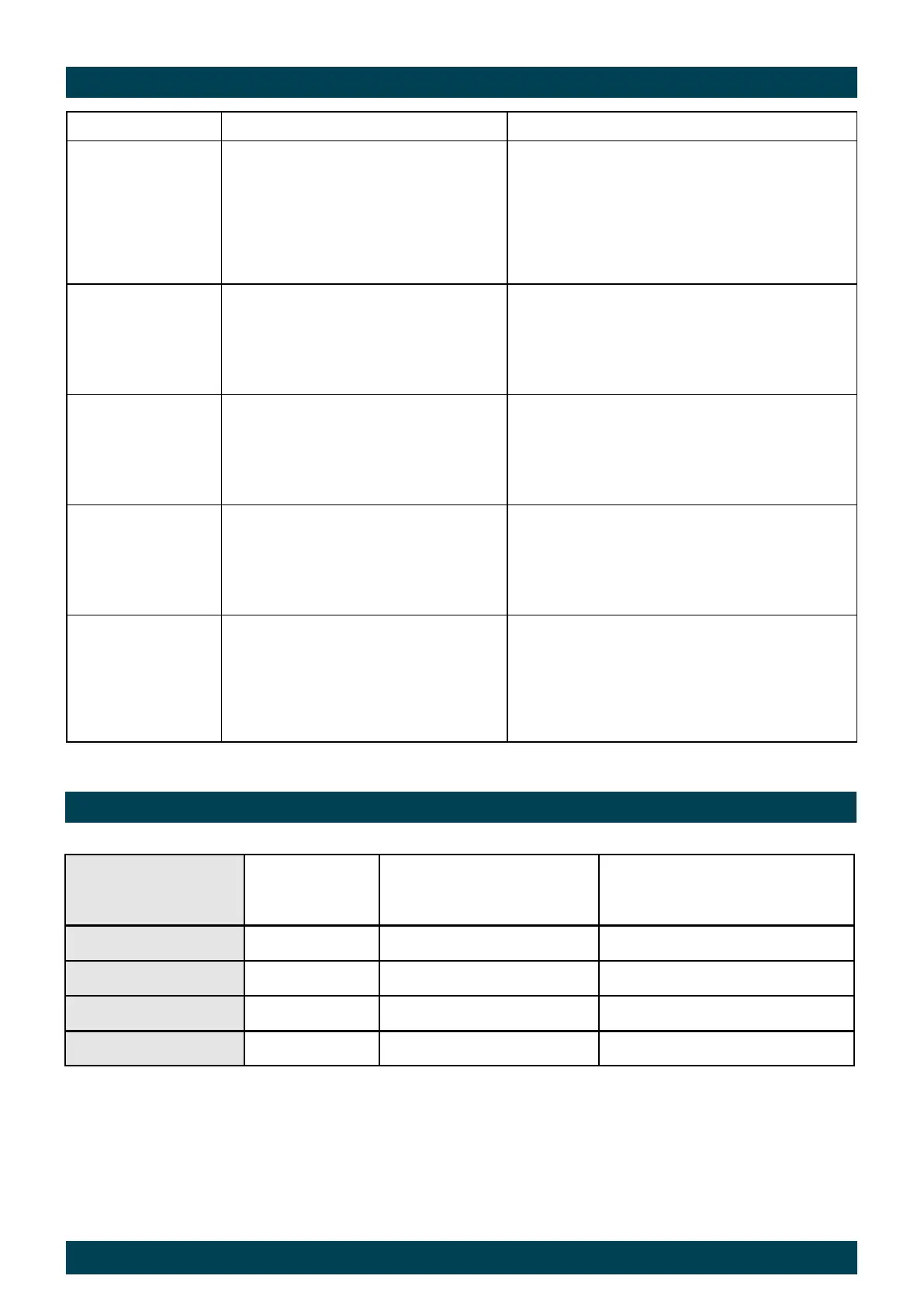

Problem Cause Remedy

Fluid will not flow

through meter

a) Foreign matter blocking rotors

b) Line strainer blocked

c) Damaged rotors

d) Meter connections over tightened

e) Fluid is too viscous

a) Dismantle meter, clean rotors (strainer must be fit-

ted in line)

b) Clean strainer

c) Replace rotors (Strainer must be fitted in line)

d) Re-adjust connections

e) See specifications for maximum viscosity

Reduced flow through

meter

a) Strainer is partially blocked

b) Fluid is too viscous

a) Clean strainer

b) See specifications for maximum viscosity

Meter reading inaccu-

rate

a) Fluid flow rate is too high or too low

b) Air in fluid

c) Excess wear caused by incorrect installa-

tion

a) See specifications for minimum and maximum flow

rates

b) Bleed air from system

c) Check meter body and rotors. Replace as required.

Refer to installation instructions

Meter not giving a

pulse signal

a) Faulty hall effect sensor

b) Faulty reed switch

c) Magnets failed

a) Replace PCB Board

b) Replace PCB Board

c) Replace magnets

LCD register not work-

ing

a) Battery not connected properly

b) Battery flat

c) Faulty wiring connections

d) Faulty LC Display

e) Faulty connection from LC Display

a) Check battery connections

b) Replace battery

c) Check wiring for loose or faulty connections

d) Replace LC Display

e) Check wiring connections

-

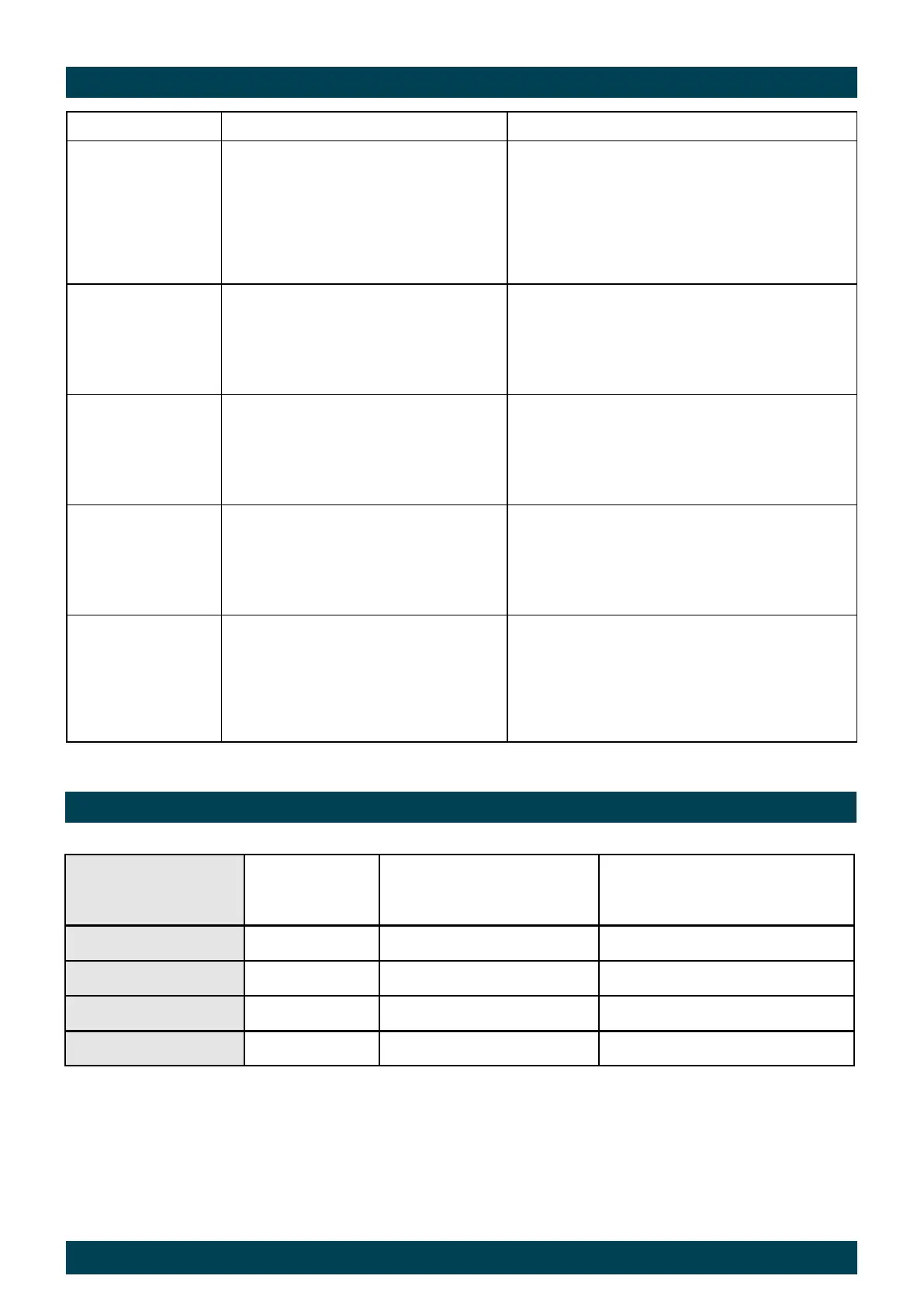

800 8.5 Nm Yes

800 5 Nm Yes

800 5 Nm Yes

75 2 Nm Yes

Loading...

Loading...