Page 6 of 19 507388-03Issue 2110

If a exible gas connector is required or allowed by

the authority that has jurisdiction, black iron pipe shall

be installed at the gas valve and extend outside the

furnace cabinet. The exible connector can then be

added between the black iron pipe and the gas supply

line.

CAUTION

Compounds used on threaded joints of gas piping must

be resistant to the actions of liqueed petroleum gases.

IMPORTANT

Never use a ame to check for gas leaks. Explosion

causing injury or death may occur.

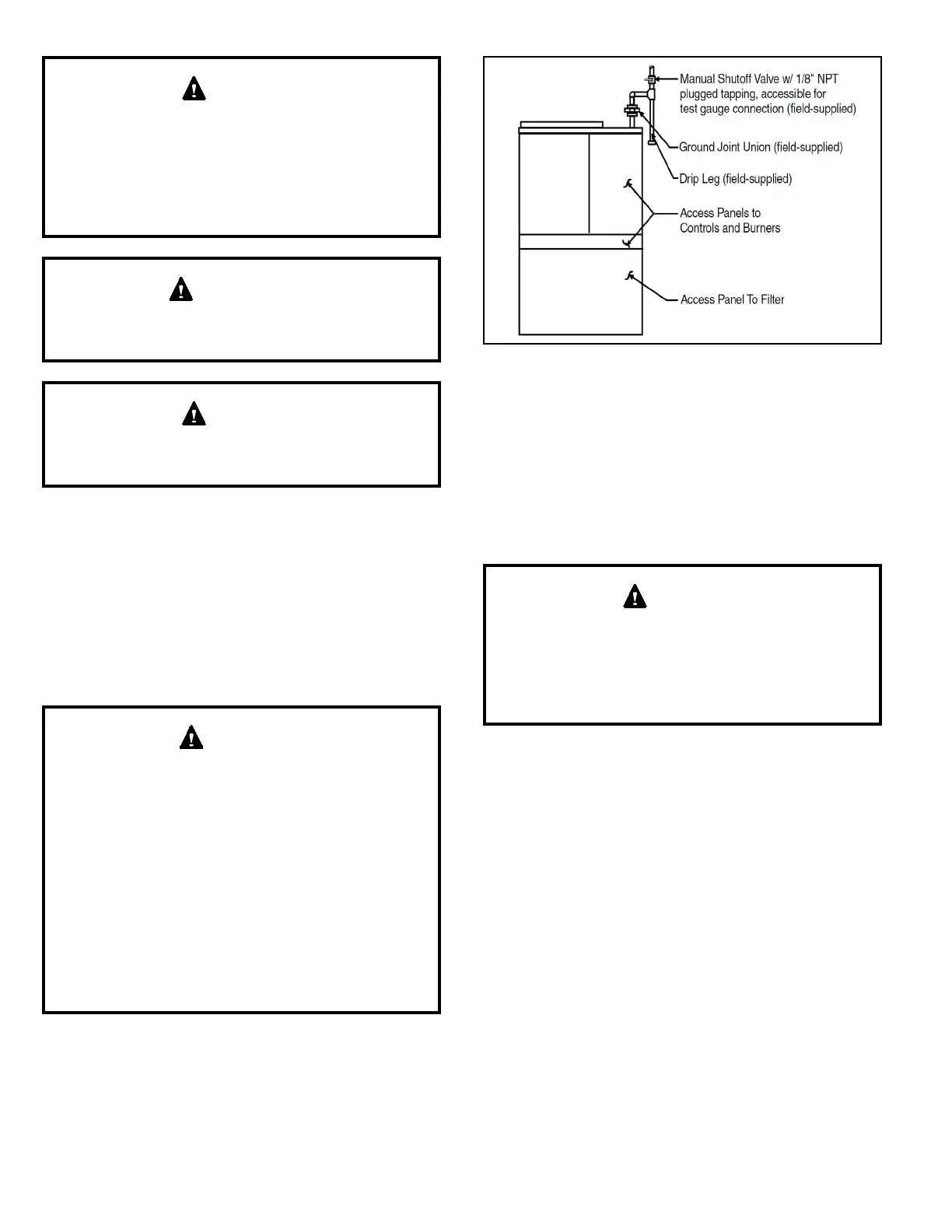

CAUTION

A manual shuto valve must be located outside the unit.

The use of a union located upstream of the controls is

recommended, between the controls, and the manual

shuto valve. This will facilitate removal of controls and

manifold. See Figure 3 for recommended placement of the

union.

Provide a drip leg in the supply piping located exterior

to the unit. Piping connections must be sealed with non-

hardening pipe joint compound resistant to propane.

The furnace must be isolated from the gas supply piping

system by closing the individual manual shuto valve

during any pressure testing of gas supply piping system

at test pressures equal to or less than 1/2 psig or 14”

W.C. If the piping system is to be tested at pressures in

excess of 1/2 psig, the furnace and its individual shuto

valve must be disconnected from the gas supply piping

system. The gas valve supplied with this furnace is

rated at 1/2 psig. Any higher pressure may rupture the

pressure regulator diaphragm which will cause over-

ring of the burners and improper burner operation.

This action may produce a high concentration of carbon

monoxide which can result in asphyxiation.

WARNING

Figure 3. Gas Supply Piping

Leak Check

After gas piping is completed, carefully check all piping

connections (factory and eld installed) for gas leaks. Use

a leak detecting solution or other preferred means.

NOTE: If emergency shuto is necessary, shut o the main

manual gas valve and disconnect the main power to the

furnace. The installer should properly label these devices.

Some soaps used for leak detection are corrosive to

certain metals. Carefully rinse piping thoroughly after

leak test has been completed. Do not use matches,

candles, ame or other sources of ignition to check for

gas leaks.

CAUTION

Loading...

Loading...