E-34

35 Series 4WD, Model - 3535, 4035, 4535 and 5035 SM June’08

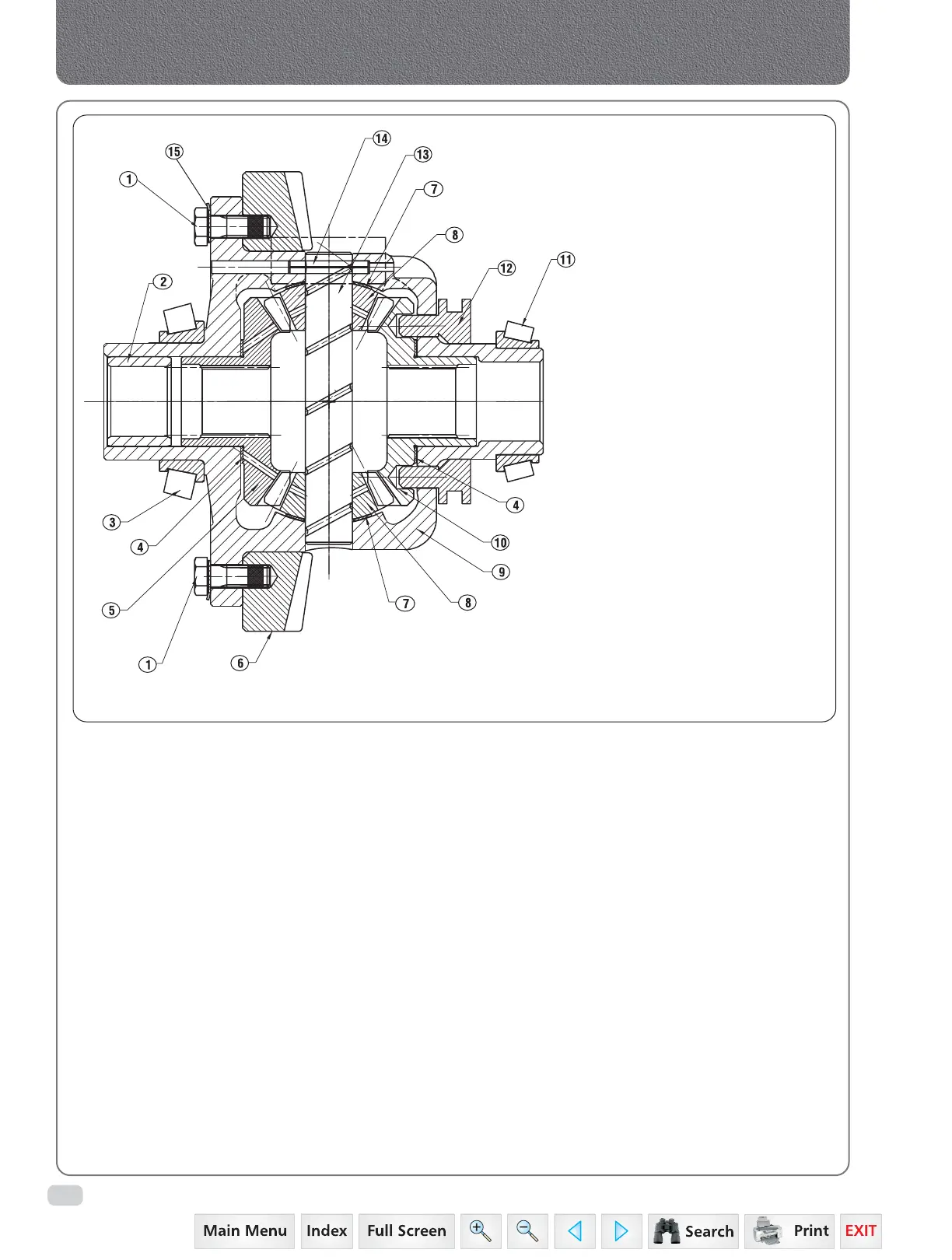

Differential

2. Description

The differential is located in the rear housing and is

mounted on two taper roller bearings. The drive bevel

(ring or crown) gear is bolted to the differential case

LH side.

The taper roller bearing is preloaded by shims located

between the differential cage and sides of the rear

housing, determine the backlash between the bevel gear

and the drive pinion and preload on the taper roller

bearings support that the differential.

Adjustment of the drive pinion and bevel gear tooth

contact is obtain by graded spacer between transmission

splined shaft bearing head and machine surface of the

housing.

The differential lock unit is incorporated which is

controlled by a foot pedal as assembled at the right

hand.

The differential gear assembly is a mechanism to provide

smooth steering. It automatically provides relative speed

to both rear wheels according to road resistance and

braking friction at the wheel.

Layout of Differential Assembly

1. Bolt

2. Bush Bull Pinion Shaft Support

3. Taper Roller Bearing

4. Thrust Washer Bevel Gear

5. Bevel Gear Differential LH

6. Gear Crown Wheel

7. Thrust Washer Bevel Pinion

8. Pinion Differential

9. Differential Case

10. Bevel Gear Differential RH

11. Taper Roller Bearing

12. Coupling

13. Shaft Differential Pinion

14. Pin Spring Differential

15. Lock Plate Bolt Diff. Case

Loading...

Loading...