E-36

35 Series 4WD, Model - 3535, 4035, 4535 and 5035 SM June’08

Differential

4. Cleaning & Inspection

a. Thoroughly clean the inside of the rear housing

and blow air.

b. Lubricate all serviceable bearing and wrap in

grease proof paper.

c. Remove all gasket material from joint face.

d. Inspect bushes for wear or damage, worn gear,

chipped or broken teeth, check splines for burrs

and correct fit. All gears should slide easily on

spline shaft but no excessive side play.

Check sliding couplings and gear for burrs and

broken teeth and worn out.

e. Check the shifter rails and forks for straightness,

wear of poppet recesses and freedom of

movements, grooves for damage.

f. Replace all not serviceable parts with new.

NOTE: Use new oil seals, ‘O’ ring and poppet springs.

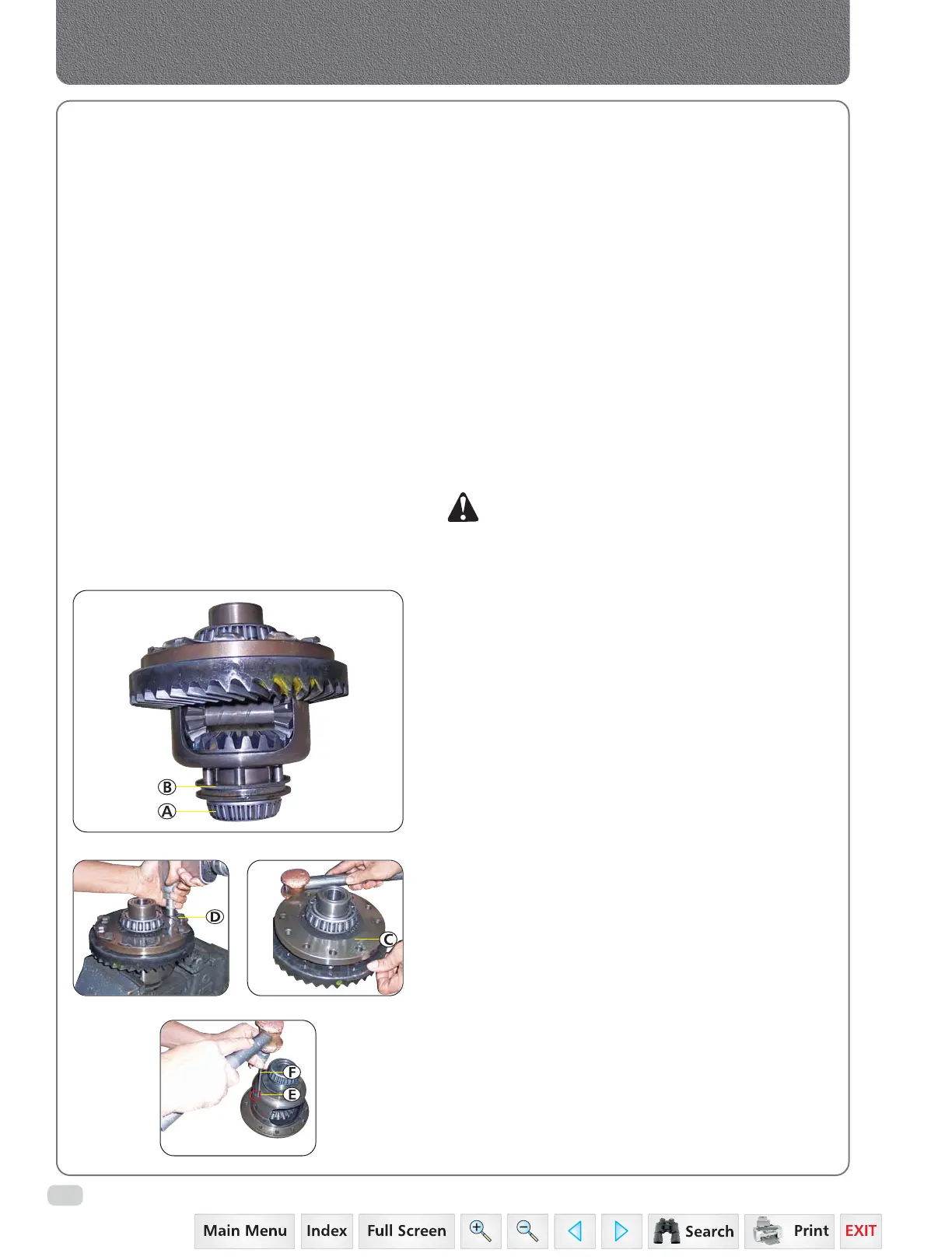

5. Dismantling of Differential Assembly

a. Place the Differential in bench-vice.

b. Remove the taper roller bearing (A) and withdraw

differential lock coupling (B).

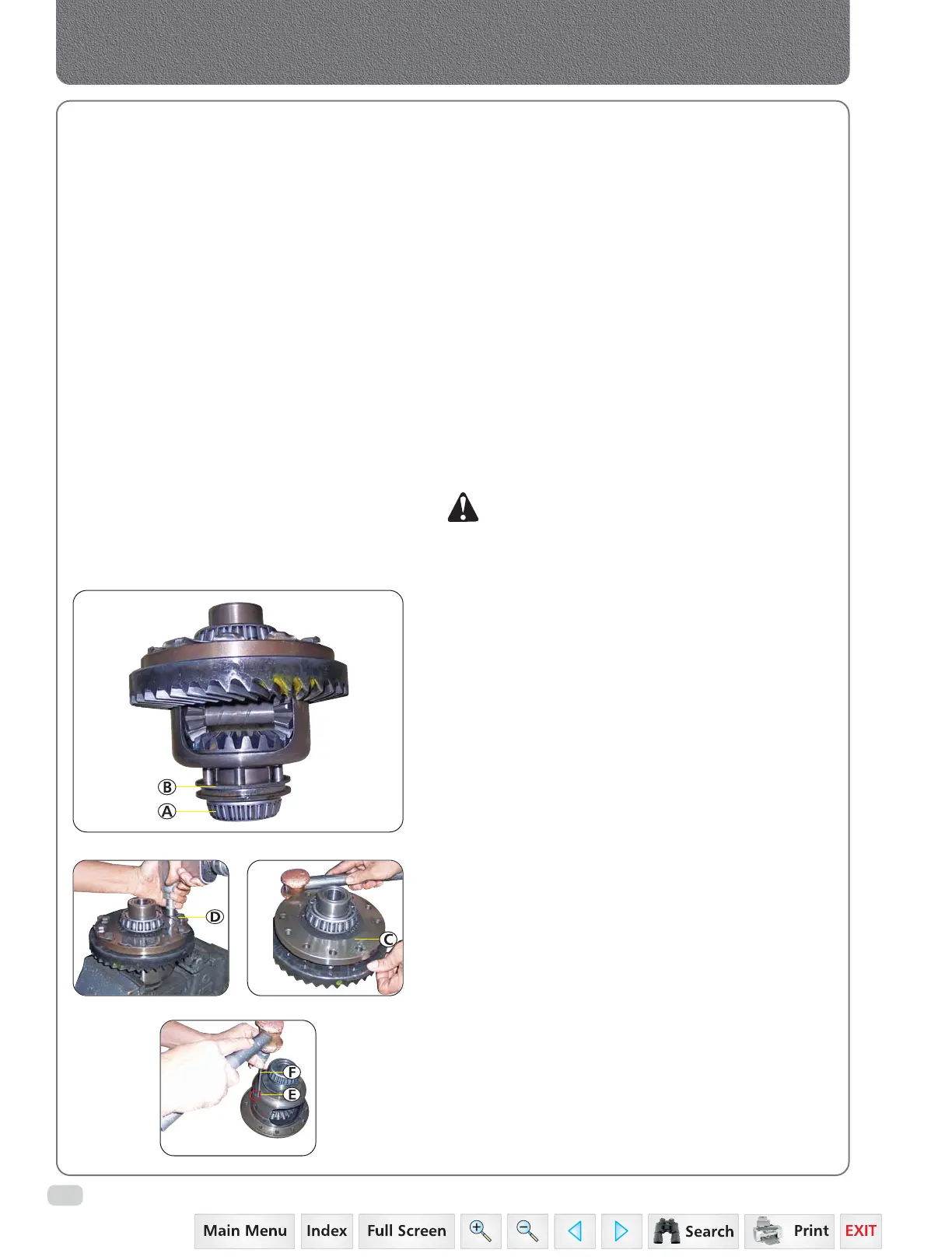

c. Remove Ring Gear (C) by loosening bolts (D).

d. Remove spring pin (E) by using Special Tool (F).

Loading...

Loading...