8 ENGLISH

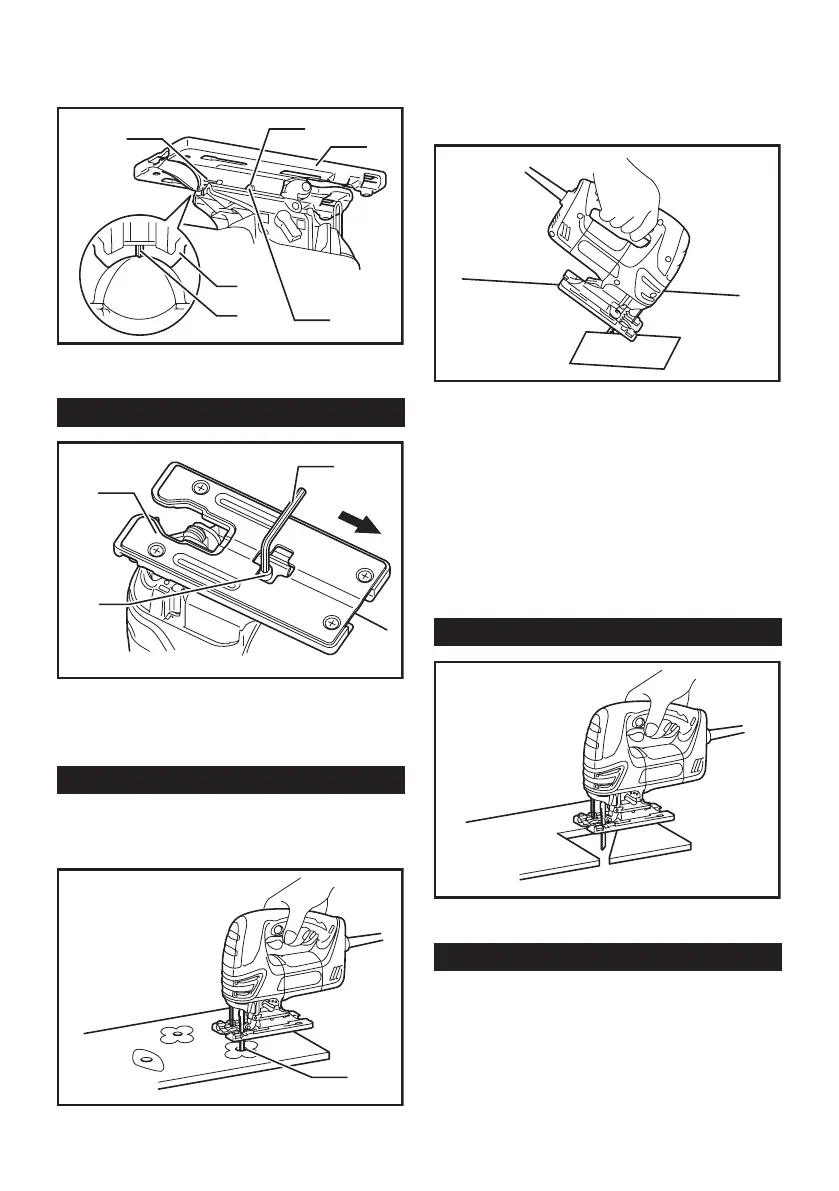

Tilt the base until the desired bevel angle is obtained.

The V-notch of the gear housing indicates the bevel

anglebygraduations.Thentightentheboltrmlyto

secure the base.

1

2

3

4

5

6

►1. Graduation 2. Bevel slot 3. Base 4. Gear housing

5. V-notch 6. Bolt

Front ush cuts

1

2

3

►1. Base 2. Bolt 3. Hex wrench

Loosen the bolt on the back of the base with the hex

wrench and slide the base all the way back. Then

tighten the bolt to secure the base.

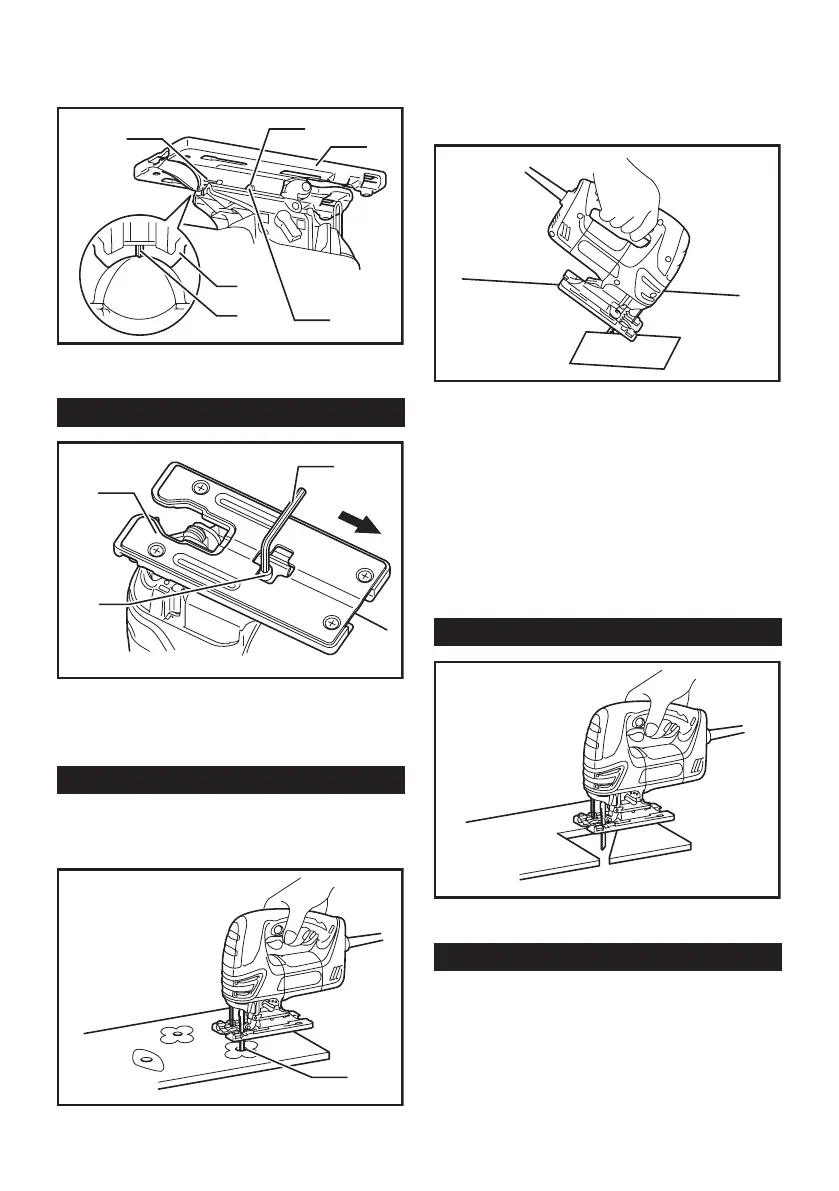

Cutouts

Cutouts can be made with either of two methods A or B.

A) Boring a starting hole:

1

►1. Starting hole

For internal cutouts without a lead-in cut from an

edge, pre-drill a starting hole 12 mm or more in

diameter. Insert the blade into this hole to start

your cut.

B) Plunge cutting:

You need not bore a starting hole or make a

lead-in cut if you carefully do as follows.

(1) Tilt the tool up on the front edge of the base

withthebladepointpositionedjustabovethe

workpiece surface.

(2) Apply pressure to the tool so that the front

edge of the base will not move when you

switch on the tool and gently lower the back

end of the tool slowly.

(3) As the blade pierces the workpiece, slowly

lower the base of the tool down onto the

workpiece surface.

(4) Complete the cut in the normal manner.

Finishing edges

Totrimedgesormakedimensionaladjustments,runthe

blade lightly along the cut edges.

Metal cutting

Always use a suitable coolant (cutting oil) when cutting

metal.Failuretodosowillcausesignicantbladewear.

The underside of the workpiece can be greased instead

of using a coolant.

Loading...

Loading...