[3] DISASSEMBLY/ASSEMBLY

[3] -2. Gear assembly, Motor section (cont.)

ASSEMBLING

(1) Assemble Gear assembly to DC motor. (Fig. 10)

(2) Assemble Speed change lever to Lever of Gear assembly. (Fig. 11)

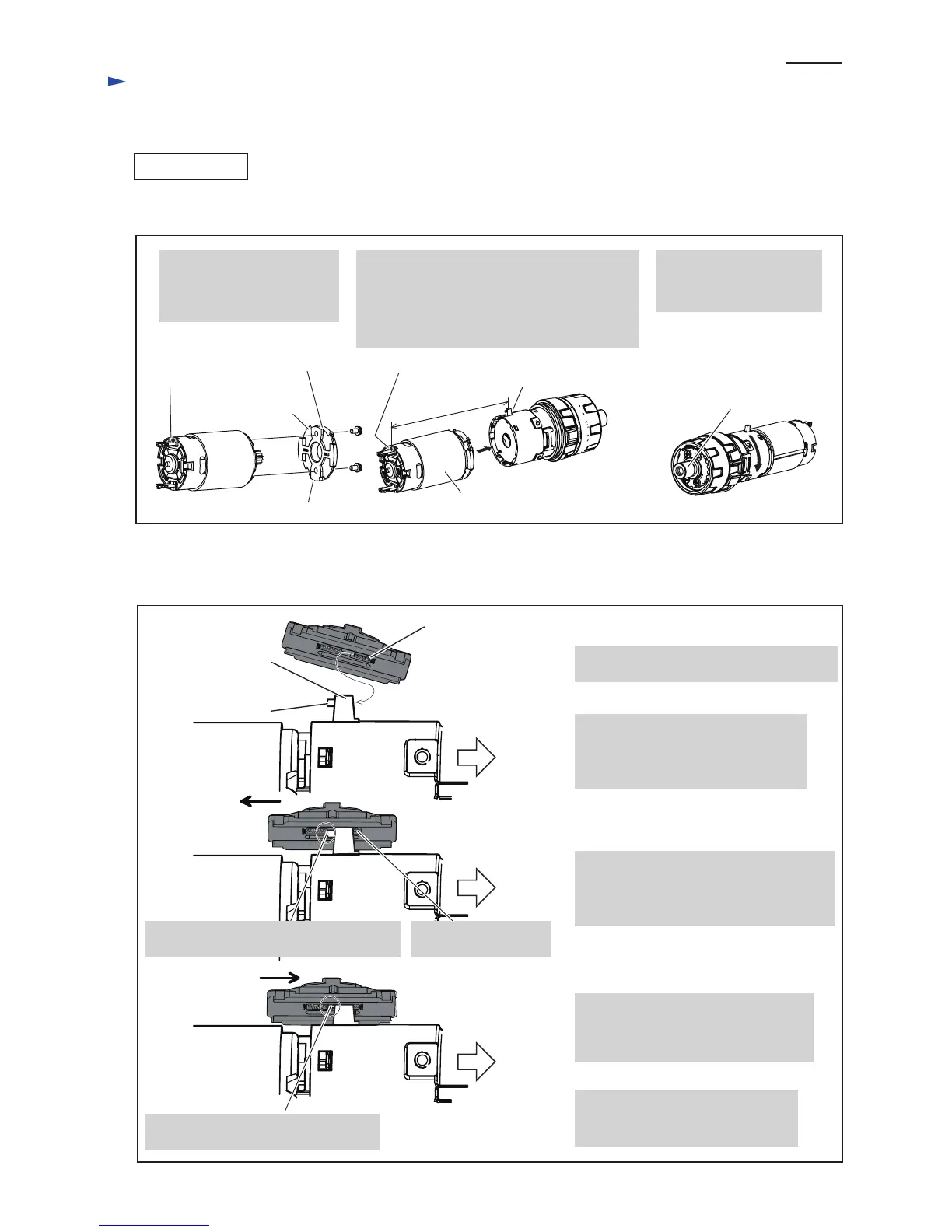

Fig. 10

1. Facing Non-projection side

to Red mark side,

assemble Motor bracket to

DC motor.

Red mark

to show

(+) terminal

Motor bracket

(Projection side)

Non- projection

side

2. While aligning the lever of Gear assembly

to Red mark on DC motor in line,

assemble Gear assembly to DC motor.

Make sure that DC motor’s pinion gear

engages with planet gears in Gear assembly.

DC motor

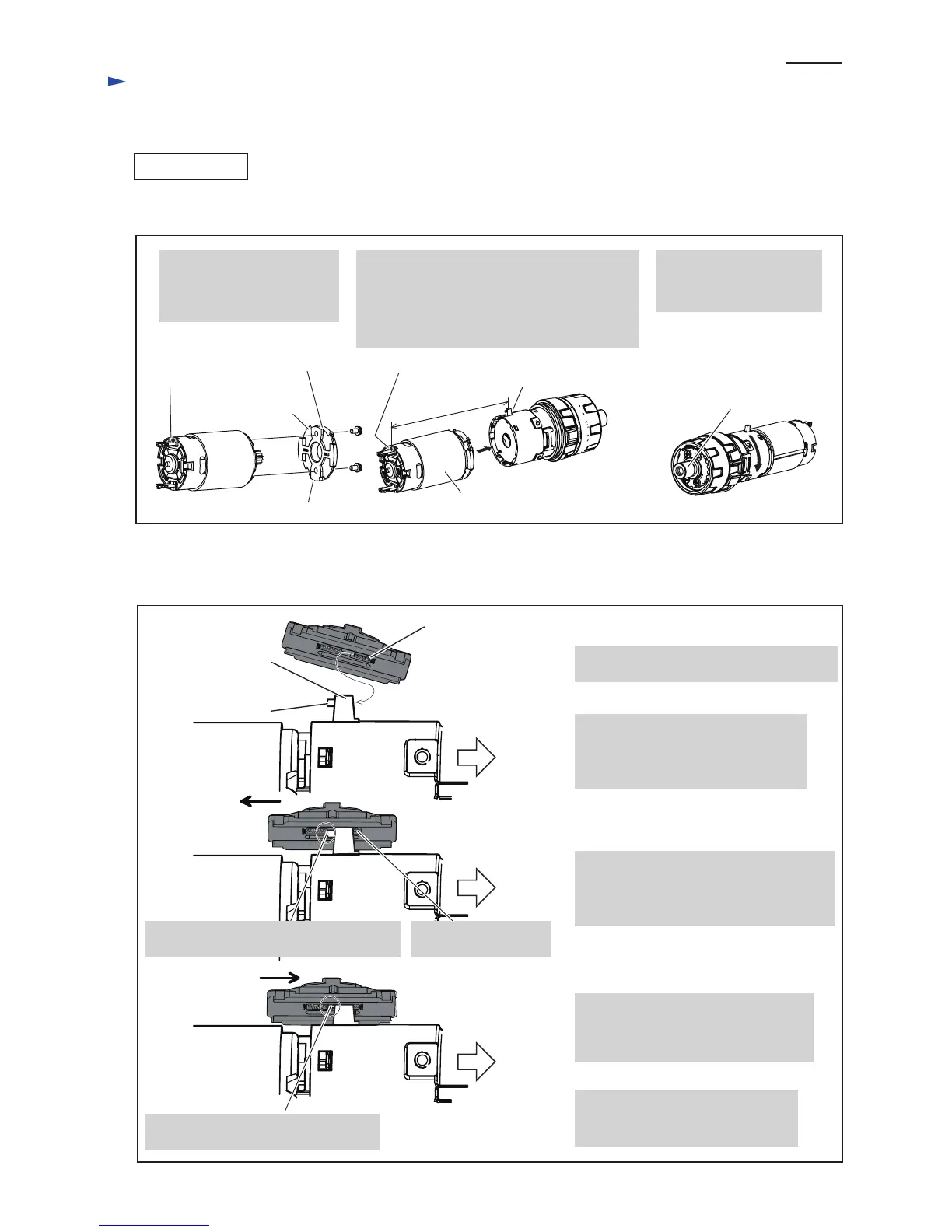

Fig. 11

Drill chuck

side

DC Motor

Drill chuck

side

DC Motor

Drill chuck

side

DC Motor

Lever of

Gear assembly

Projection of

Gear assembly

Front end of Compression spring 4

1.Make sure 2 pcs. of Compression spring 4

are mounted to Speed change lever.

2. Apply the front end of Compression

spring 4 of Speed change lever to

the flat side (Non-projection side)

of Lever of Gear assembly

Space between rear Compression spring 4

and Projection.

3. Push Speed change lever toward

Motor side until it stops to have space

between the projection of Gear assembly

and the rear end of Compression spring 4.

4. Fit the projection of Gear assembly

into Compression spring 4, returning

Speed change lever slowly toward

Drill chuck side.

5. Slide Speed change lever to either

position 2 (High speed mode) or

1 (Low speed mode).

Projection fit to the coil of rear end of

Compression spring 4

Compression spring 4

compressed by Lever

Red mark Lever of Gear assembly

for speed change

3. Turn Gear assembly

clockwise viewed from

Spindle side.

Spindle

Repair

P 6/ 11

Loading...

Loading...