6 ENGLISH

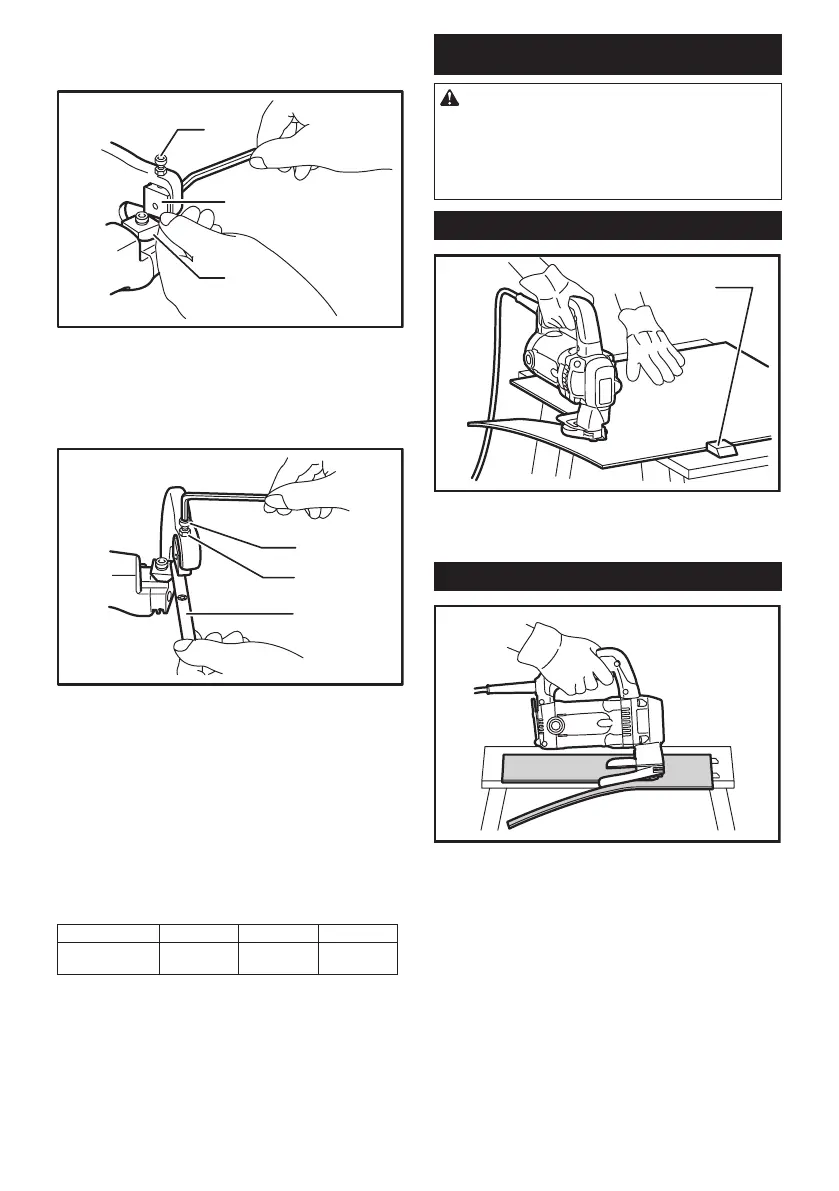

After securing the upper blade, be sure that there is no

gap left between the upper blade and the beveled sur-

face of the blade holder.

1

2

3

► 1. Lower blade positioning bolt 2. Lower blade

3. Upper blade

Then install the lower blade like the upper blade while

adjusting the clearance between the upper blade and

lower blades. When performing this adjustment, the

upper blade should be in the lowered position.

1

2

3

► 1. Lower blade positioning bolt 2. Hex nut

3. Thickness gauge

First, semi- tighten the lower blade securing bolt, then

insert the thickness gauge for the desired clearance.

The cutting thickness is indicated on the thickness

gauge so the combinations shown in the table below

should be used. Work the lower blade positioning bolt

on the yoke until the clearance is such that the thick-

ness gauge moves only with some difculty. Then rmly

tighten the lower blade securing bolt. Finally, tighten the

hex nut to secure the lower blade positioning bolt.

Thickness gauge combinations

Material thickness

2.3 mm (14 ga.) 2.5 mm (13 ga.) 3.2 mm (10 ga.)

Thickness gauge

combinations

1.0 +1.5 1.0 +1.5 1.5 + 2.0

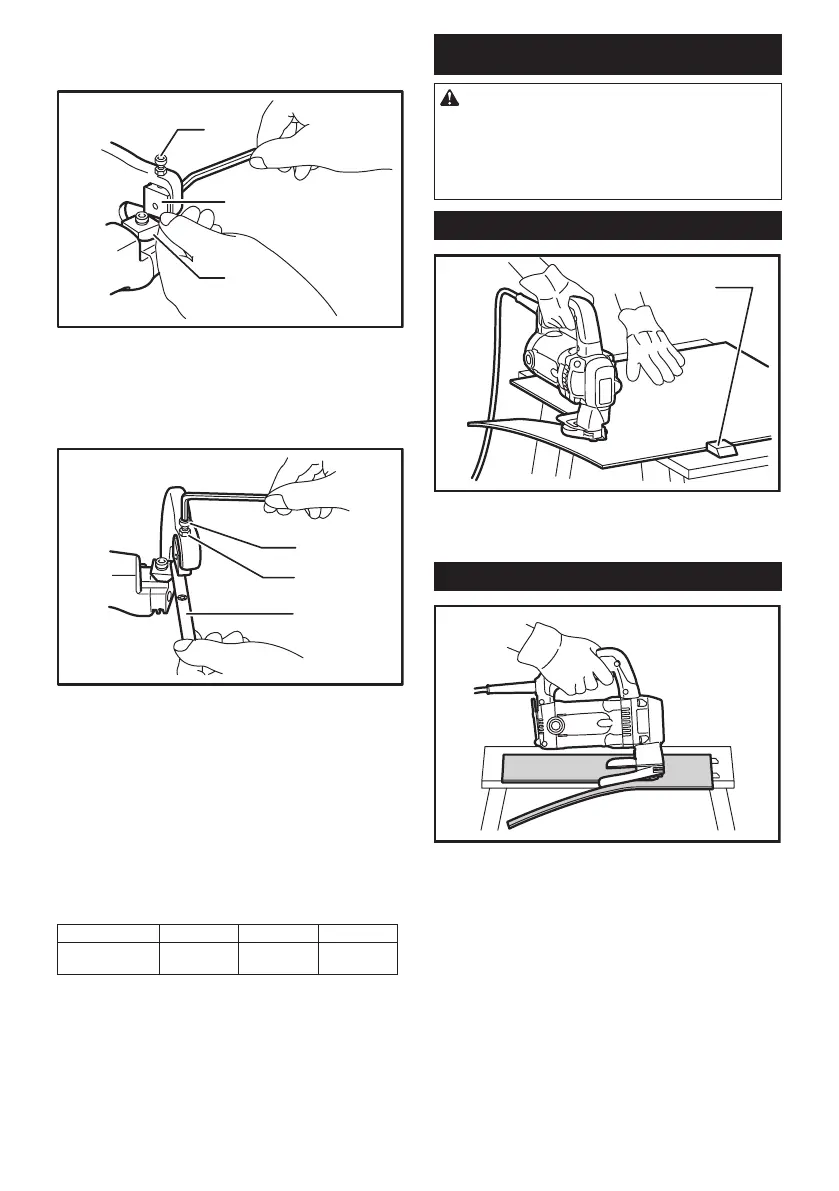

OPERATION

CAUTION:

• When cutting, always place the shear on the

workpiece so that the material cut away is posi-

tioned on the right side to the operator.

• Hold the tool rmly with one hand on the main

handle when performing the tool.

Holding material

1

► 1. Workholder

The materials for cutting should be fastened to the

workbench by means of workholders.

Shearing method

For smooth cuts, tip the tool slightly backward while

advancing it.

Loading...

Loading...